Palladium-tin nano-chain network catalyst and preparation method and application thereof

A technology of nano chains and catalysts, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as hidden safety hazards and environmental pollution, and achieve high practical value, easy operation and repeatability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

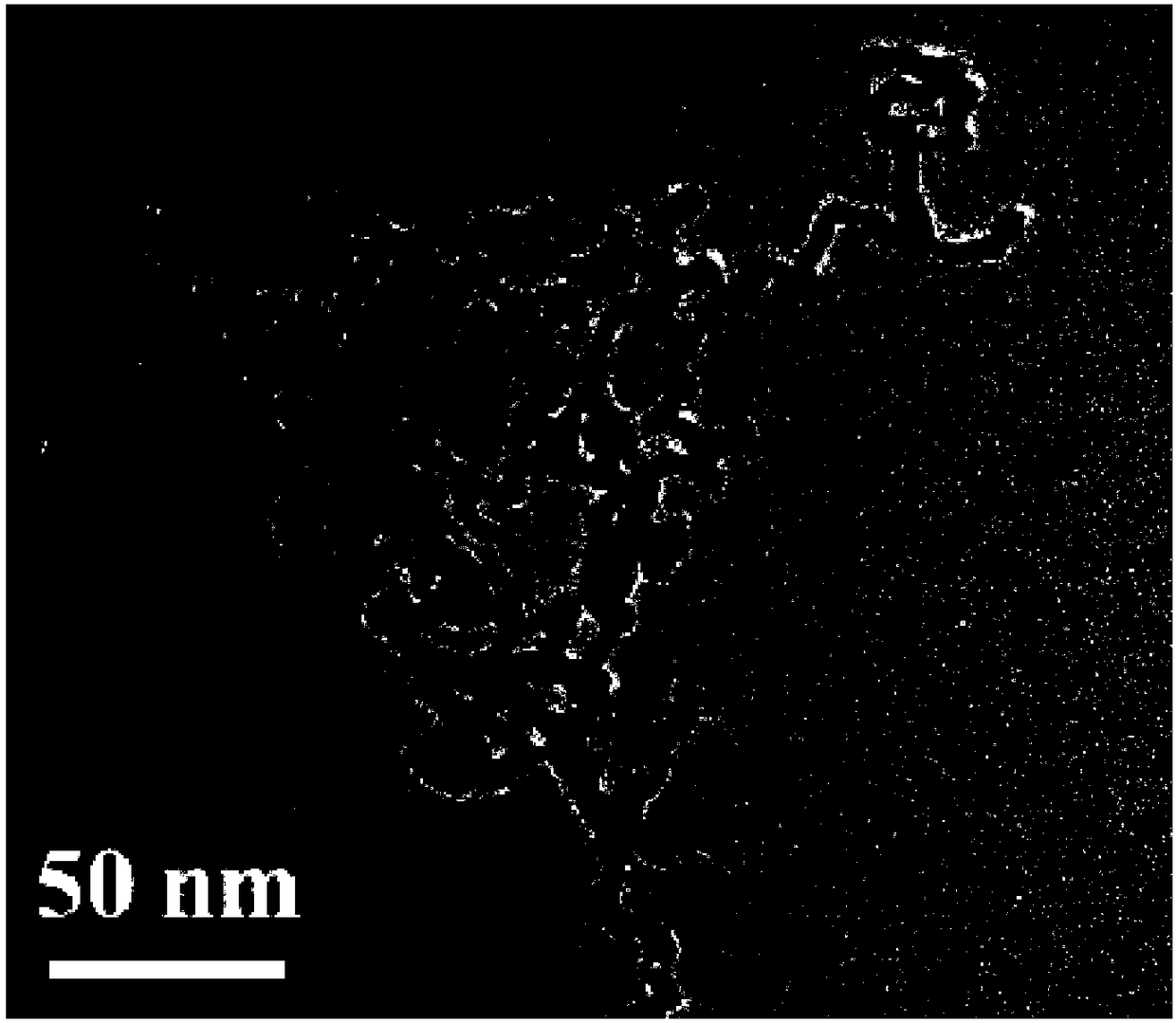

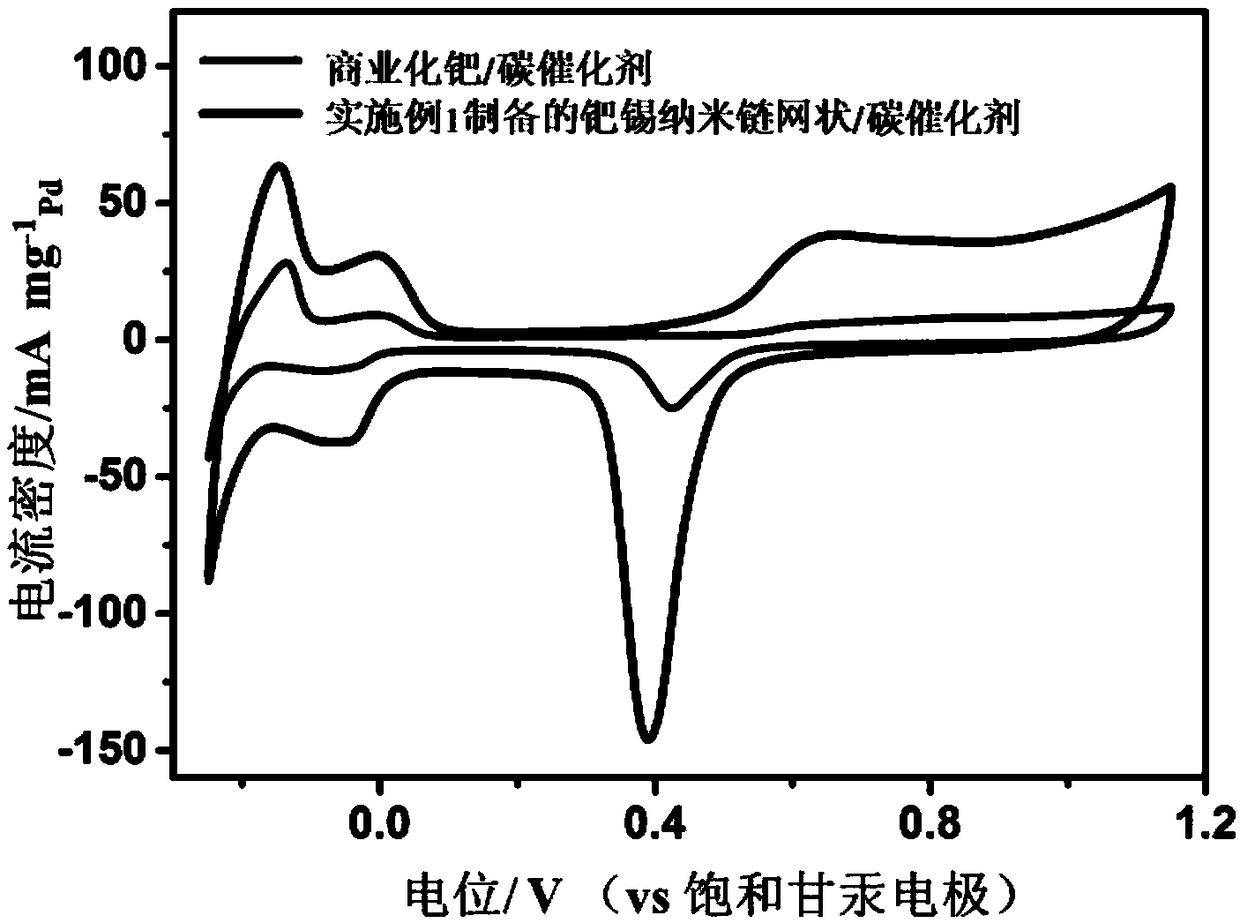

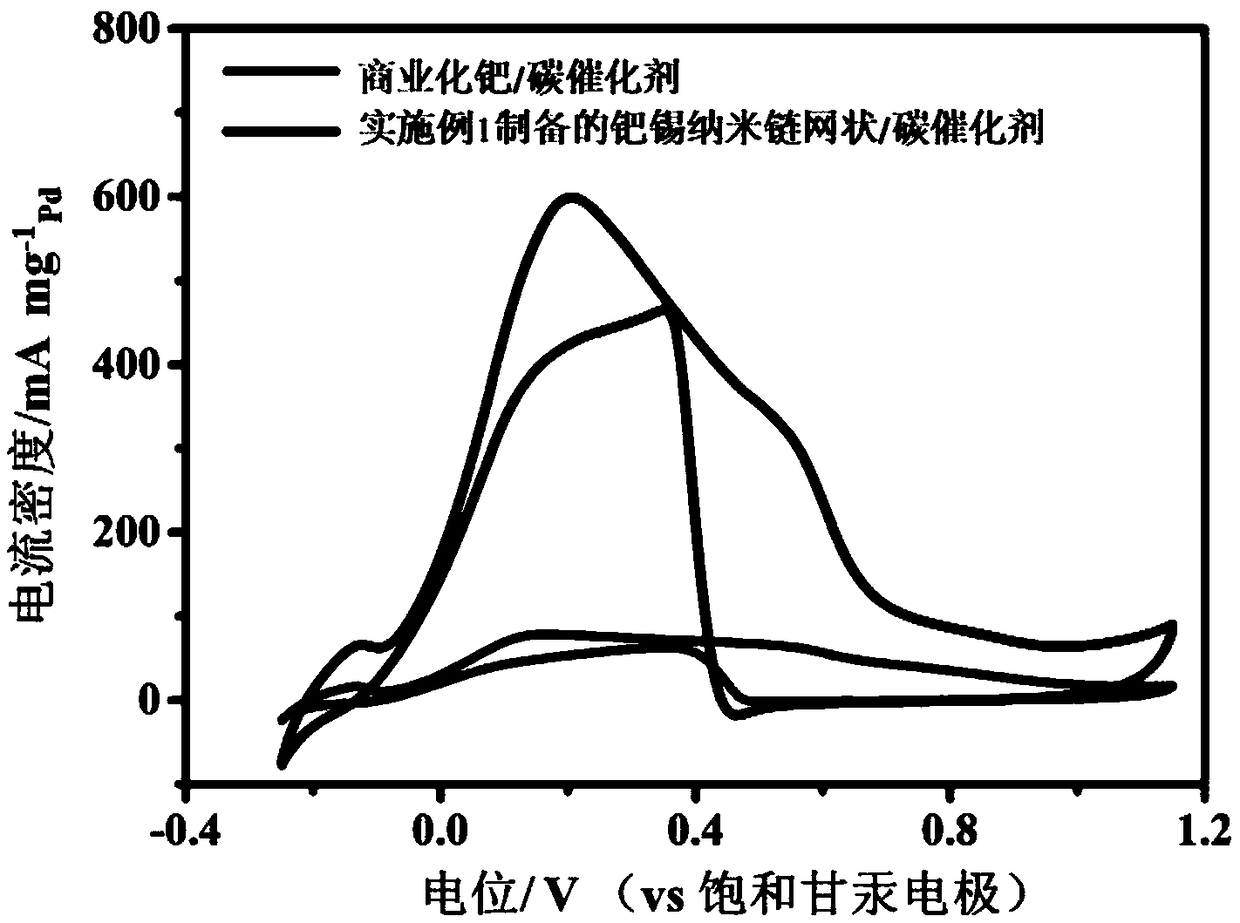

Embodiment 1

[0037] The preparation method of the present embodiment 1 palladium tin nano-chain network catalyst comprises the following steps:

[0038] (1) Add 60mg of polyvinylpyrrolidone (PVP) to 30mL of ethylene glycol solution and sonicate for 10min with a power of 600W;

[0039] (2) Add 22.74mg of ammonium chloropalladate, 4.53mg of stannous chloride dihydrate and 15mg of citric acid into the solution obtained in step (1) and sonicate for 5min with a power of 600W;

[0040] (3) Transfer the mixed solution obtained in step (2) to a 50mL hydrothermal kettle, heat to 80°C for 3h, then raise the temperature to 220°C for 15h;

[0041] (4) The product obtained in step (3) is mixed solution of ethanol and water with a volume ratio of 1:1 at 15000rpm min -1 Centrifuge for 20 minutes at a high speed, repeat washing 3 times, and then ultrasonicate for 10 minutes at a power of 600W to disperse in 10 mL of ethanol;

[0042] (5) Add 19.23mg of XC-72 carbon powder into 20mL of ethanol and sonica...

Embodiment 2

[0050] The preparation method of the present embodiment 2 palladium tin nano-chain network catalyst comprises the following steps:

[0051] (1) Add 60mg of polyvinylpyrrolidone (PVP) to 30mL of ethylene glycol solution and sonicate for 10min with a power of 600W;

[0052] (2) Add 22.74mg of ammonium chloropalladate, 4.53mg of stannous chloride dihydrate and 15mg of citric acid into the solution obtained in step (1) and sonicate for 5min with a power of 600W;

[0053] (3) Transfer the mixed solution obtained in step (2) to a 50mL hydrothermal kettle, heat to 90°C for 3h, then raise the temperature to 200°C for 10h;

[0054] (4) The product obtained in step (3) is mixed solution of ethanol and water with a volume ratio of 1:1 at 15000rpm min -1 Centrifuge at the speed of 20min, and repeat cleaning 3 times, then ultrasonic for 10min, the power is 600W, make it dispersed in 10ml ethanol;

[0055] (5) Add 19.23mg of XC-72 carbon powder into 20mL of ethanol and sonicate for 30min ...

Embodiment 3

[0063] The preparation method of the present embodiment 3 palladium tin nano-chain network catalyst comprises the following steps:

[0064] (1) Add 60mg of polyvinylpyrrolidone (PVP) to 30mL of ethylene glycol solution and sonicate for 10min with a power of 600W;

[0065] (2) Add 22.74mg of ammonium chloropalladate, 4.53mg of stannous chloride dihydrate and 15mg of citric acid into the solution obtained in step (1) and sonicate for 5min with a power of 600W;

[0066] (3) Transfer the mixed solution obtained in step (2) to a 50mL hydrothermal kettle, heat to 80°C for 3h, then raise the temperature to 220°C for 10h;

[0067] (4) The product obtained in step (3) is mixed solution of ethanol and water with a volume ratio of 1:1 at 15000rpm min -1 Centrifuge at the speed of 20min, and repeat cleaning 3 times, then ultrasonic for 10min, the power is 600W, make it dispersed in 10ml ethanol;

[0068] (5) Add 19.23mg of XC-72 carbon powder into 20mL of ethanol and sonicate for 30min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com