Novel low-noise low-vibration permanent magnet motor stator rotor punching sheet

A permanent magnet motor and stator punching technology, which is applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of electromagnetic noise and high vibration, reduce vibration and electromagnetic noise, improve torque constant, and meet the requirements of carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

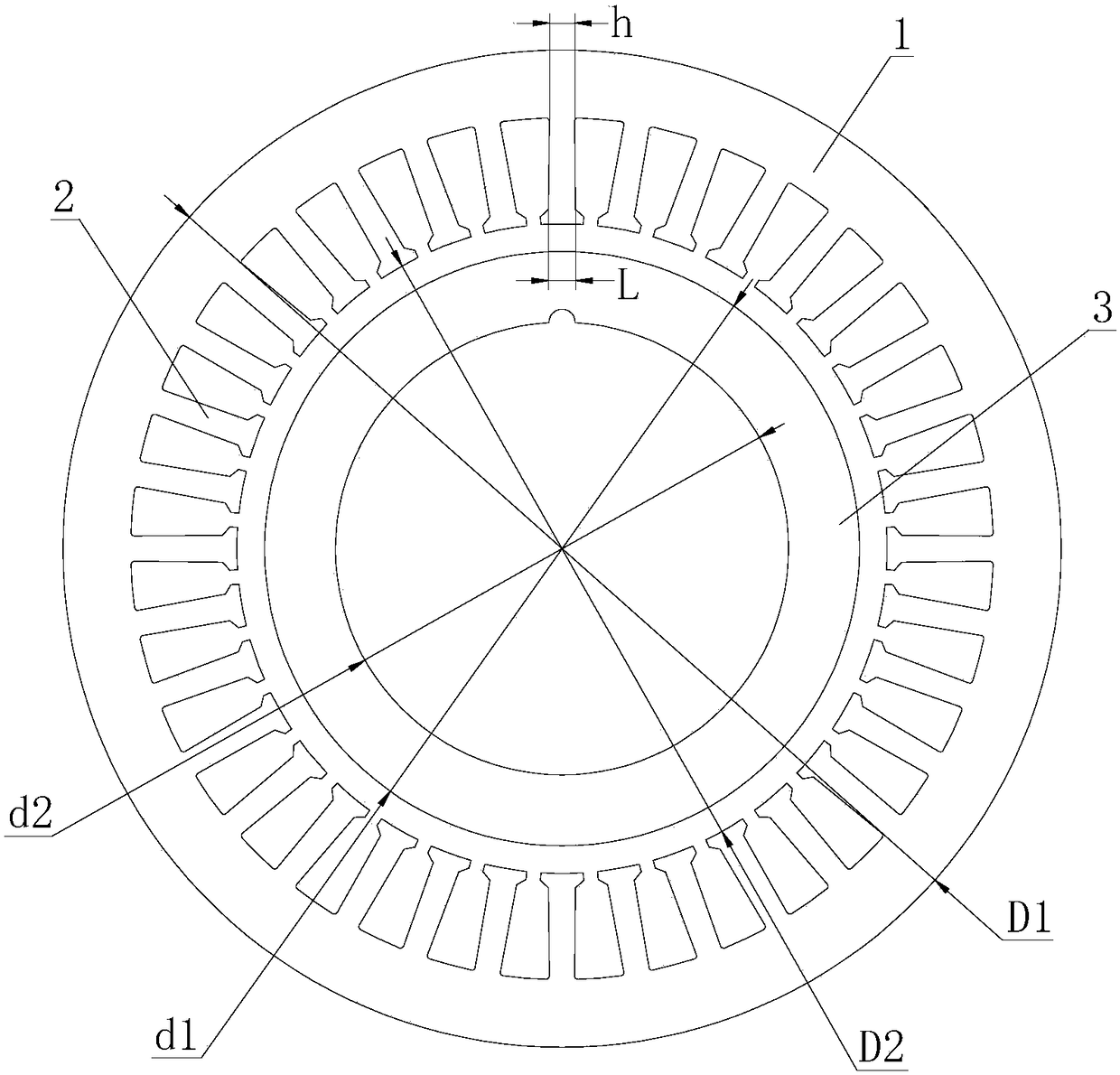

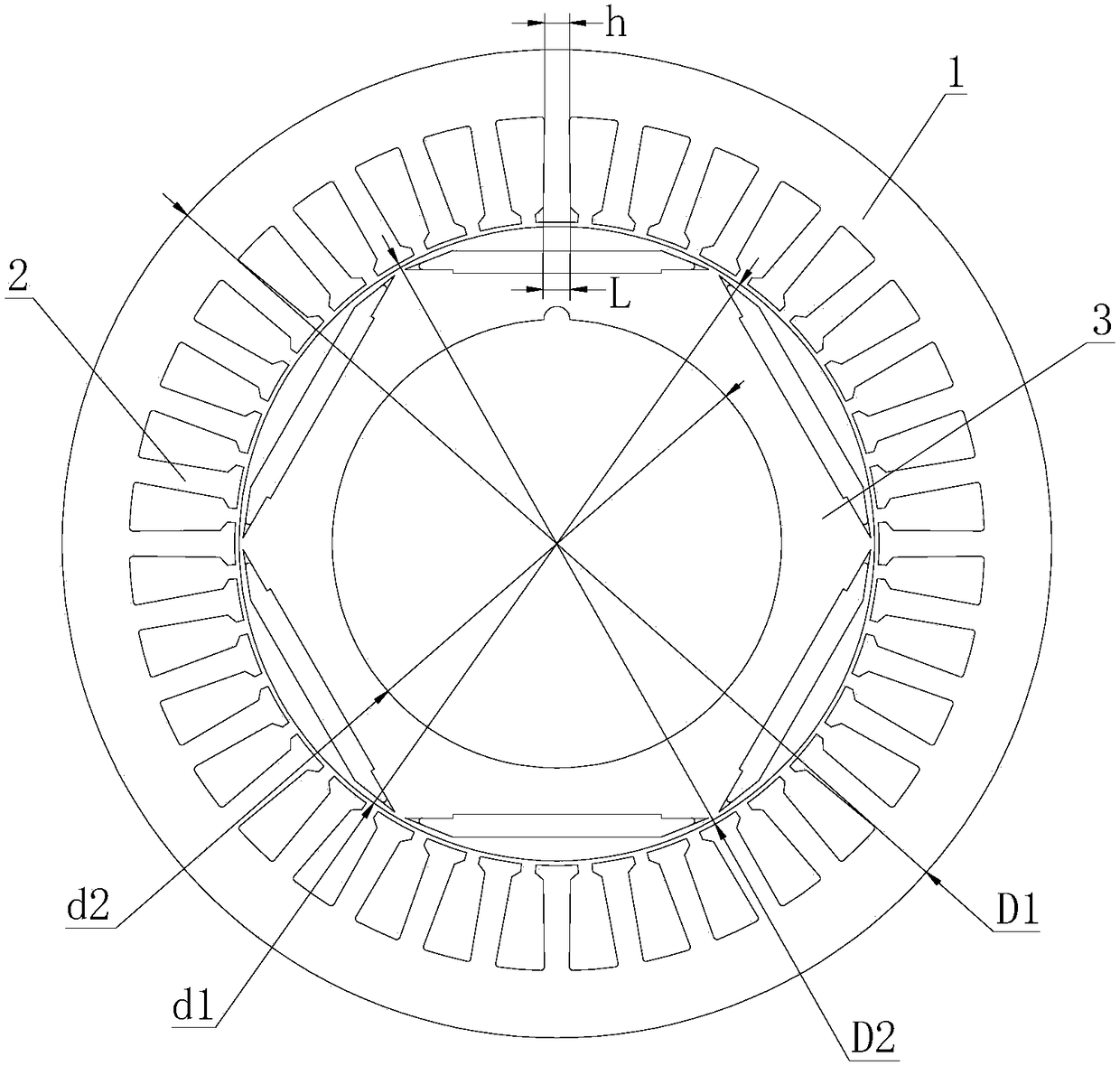

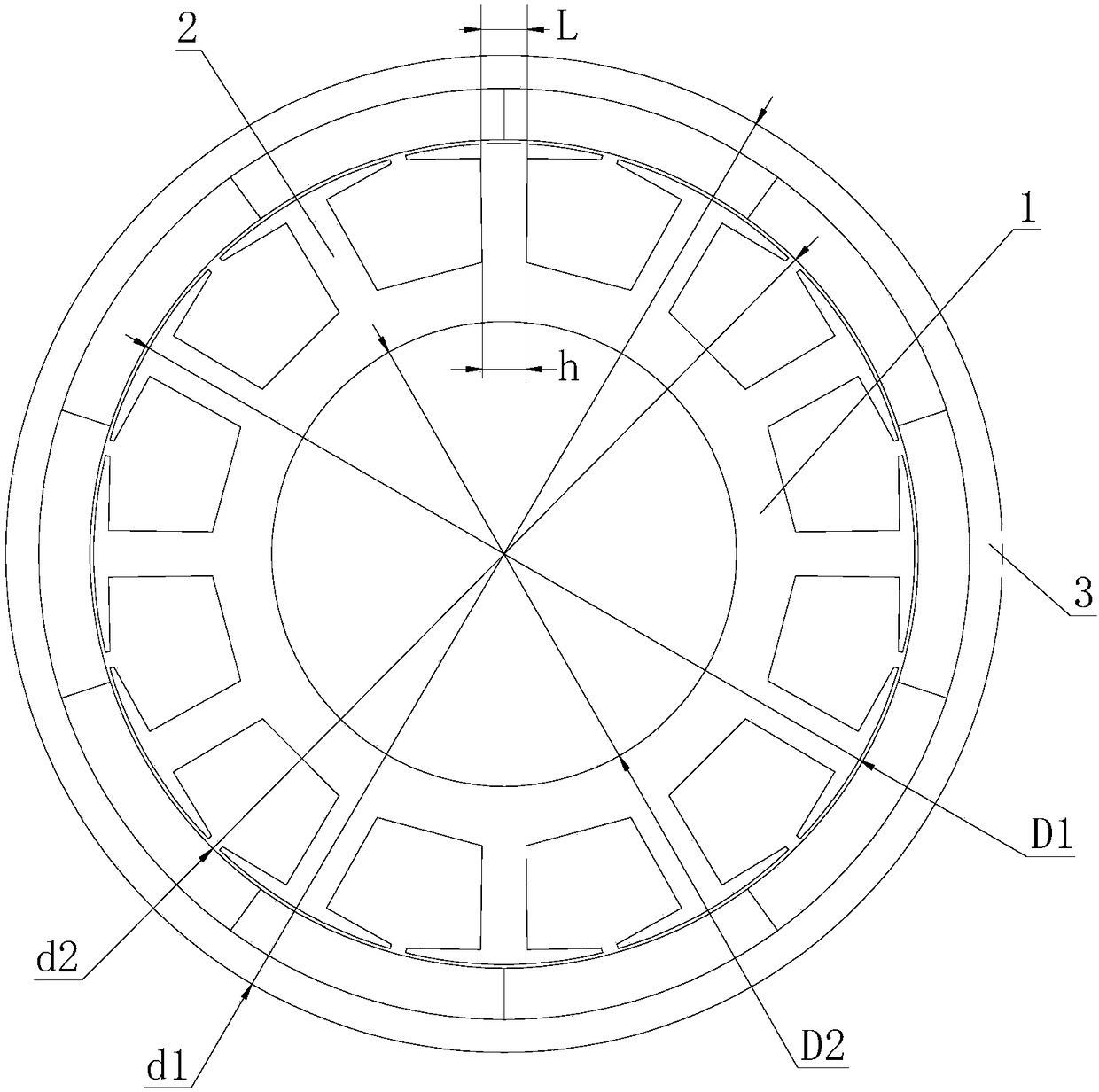

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1-3 As shown, the above-mentioned stator and rotor stamping of a new type of low-noise and low-vibration permanent magnet motor, the stator stamping includes a stator yoke 1 whose magnetic density of the stator yoke is not greater than 1T, and the stator yoke 1 is larger than the average yoke of the existing stator yoke. The width of the part is at least 1.35 times. Considering the punching burrs are up to 0.054mm and the lamination coefficient is 0.9, the loss is up to 0.12, which is also 1.23 times wider than the existing stator yoke part, which can ensure that the magnetic circuit of the stator yoke part 1 will never be saturated. The stator punching sheet also includes a trapezoidal tooth portion 2 with a magnetic density of not more than 1.5T. The trapezoidal tooth portion 2 is at least 1.13 times wider than the average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com