A kind of preparation method and application of titanium-based nanosheet composite catalyst

A technology of composite catalysts and nanosheets, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems that have not been seen, and achieve the effects of simple preparation methods, improved degradation activity, and high catalytic degradation activity

Active Publication Date: 2019-10-01

HEBEI UNIV OF TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Recent studies have shown that the morphology and structure of the catalyst support have an important influence on the reactivity of the catalyst, but so far, the research on the preparation method of the catalyst involved in the degradation of chlorinated aromatics is limited to the chemical composition and crystal structure of the support. The effect of phase structure on catalyst activity, there is no research report on the research and development of composite nanocatalysts for the efficient degradation of chlorinated aromatic hydrocarbons based on the design of catalyst carrier morphology

In recent years, the catalytic activity of manganese and cerium metal oxides has been studied, but no TiO 2 A report on the development of a new catalyst for the degradation of chlorinated aromatic hydrocarbons by assembling the active components of manganese and cerium metal oxides on the carrier

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

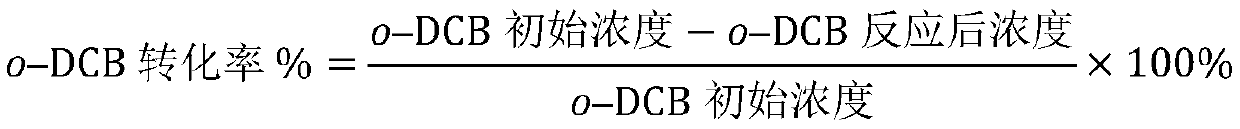

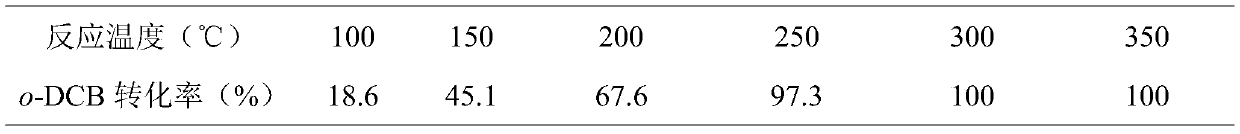

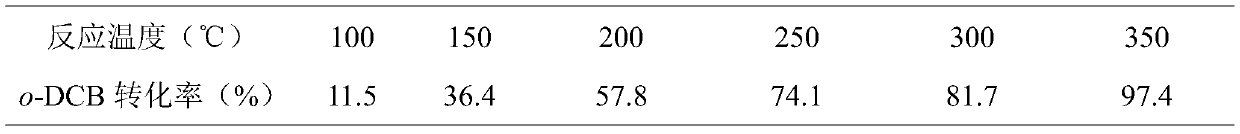

The invention relates to a preparation method and application of a titanium-based nano-sheet composite catalyst. The preparation method comprises the following steps: taking tetrabutyl titanate as a titanium source and regulating and controlling hydrothermal synthesis conditions to prepare a TiO2 nano-sheet carrier capable of preferentially exposing a (001) crystal surface; loading manganese and cerium metal oxide active components to prepare the titanium-based nano-sheet composite catalyst. According to the catalyst prepared by the invention, the (001) crystal surface, which is preferentiallyexposed, of a TiO2 nano-sheet, and the manganese and cerium metal oxide active components have a strong mutual effect, and efficient catalytic oxidation on chlorinated aromatic hydrocarbon can be realized.

Description

technical field The invention relates to a preparation method and application of a titanium-based nanosheet composite catalyst. Background technique Some secondary pollutants will be produced in the process of waste incineration. Among them, chlorinated aromatic hydrocarbons with high toxicity, persistence and bioaccumulation, such as dioxins, polychlorinated biphenyls, and hexachlorobenzene, have become widely concerned. focus. At present, the research on the reduction technology and control principle of chlorinated aromatic hydrocarbons in waste incineration tail gas has become one of the hotspots in the field of environmental chemistry. The technologies for controlling chlorinated aromatics pollutants in incineration tail gas are mainly adsorption method and catalytic oxidation method. The traditional adsorption method only transfers and enriches the pollutants from the gas phase to the solid phase. The physical and chemical properties of the pollutants have not change...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J23/34B01D53/86B01D53/70

Inventor 马小东

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com