Sulfur-containing organic waste gas catalytic oxidation catalyst and preparation method thereof

A technology for catalytic oxidation and organic waste gas, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of inability to achieve efficient oxidation of organic sulfur and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

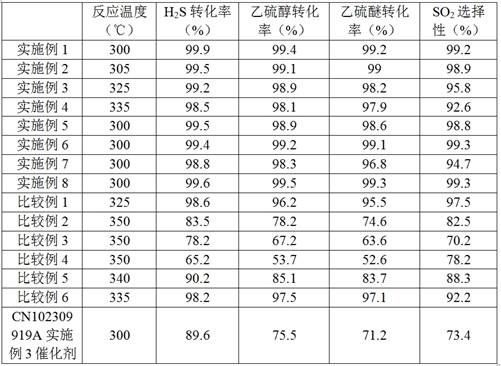

Examples

Embodiment 1

[0031] (1) Dissolve ammonium metavanadate in oxalic acid solution, wherein the mass ratio of ammonium metavanadate to oxalic acid is 1:5, and the concentration of ammonium metavanadate is 1.15mol / L. The equal volume of SSZ-13 molecular sieve was impregnated in the active component precursor solution, dried at 100°C for 4 hours, and calcined at 500°C for 4 hours to obtain a composite powder, in which the active component accounted for 15% of the mass of the compound.

[0032] (2) Dilute nitric acid with a pH of 1.5, pseudoboehmite powder, anatase titanium dioxide, methyl cellulose, and deionized water were prepared into a slurry at a mass ratio of 50:25:30:2:100, and ball milled for 15 hours , the honeycomb ceramic carrier was immersed in the coating slurry for 2 minutes, dried at 100°C for 4 hours, and fired at 500°C for 4 hours to obtain a honeycomb carrier coated with titania-alumina coating, wherein the mass of titania accounted for the honeycomb carrier 5%, the mass of alu...

Embodiment 2

[0035] The preparation method of this example is the same as that of Example 1, except that the concentration of ammonium metavanadate in step (1) is 1.5 mol / L. Based on the mass of the honeycomb carrier, the content of SSZ-13 molecular sieve is 2%, and the content of active components in terms of vanadium pentoxide is 0.48%.

Embodiment 3

[0037] The preparation method of this example is the same as that of Example 1, except that the concentration of ammonium metavanadate in step (1) is 0.8 mol / L. Based on the mass of the honeycomb carrier, the content of SSZ-13 molecular sieve is 2%, and the content of active components in terms of vanadium pentoxide is 0.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com