Multi-angle crushing mechanism for glass pulverizer

A crushing mechanism and technology of a crushing machine, applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problem of low specific gravity in the effective crushing time of the crushing chamber, reducing the service life of the crushing machine, glass crushing machine Stuck and other problems, to achieve good crushing effect, soft texture, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

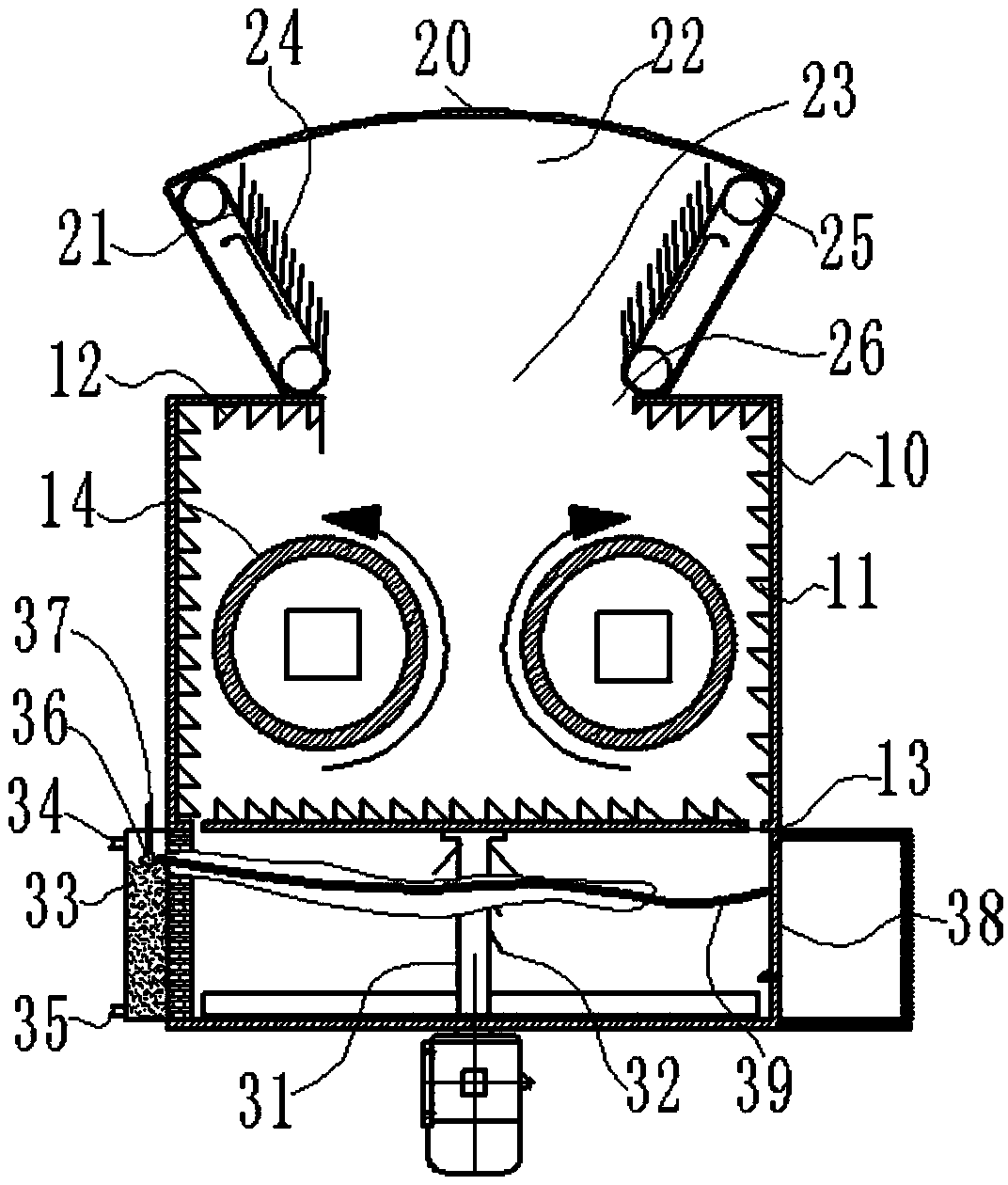

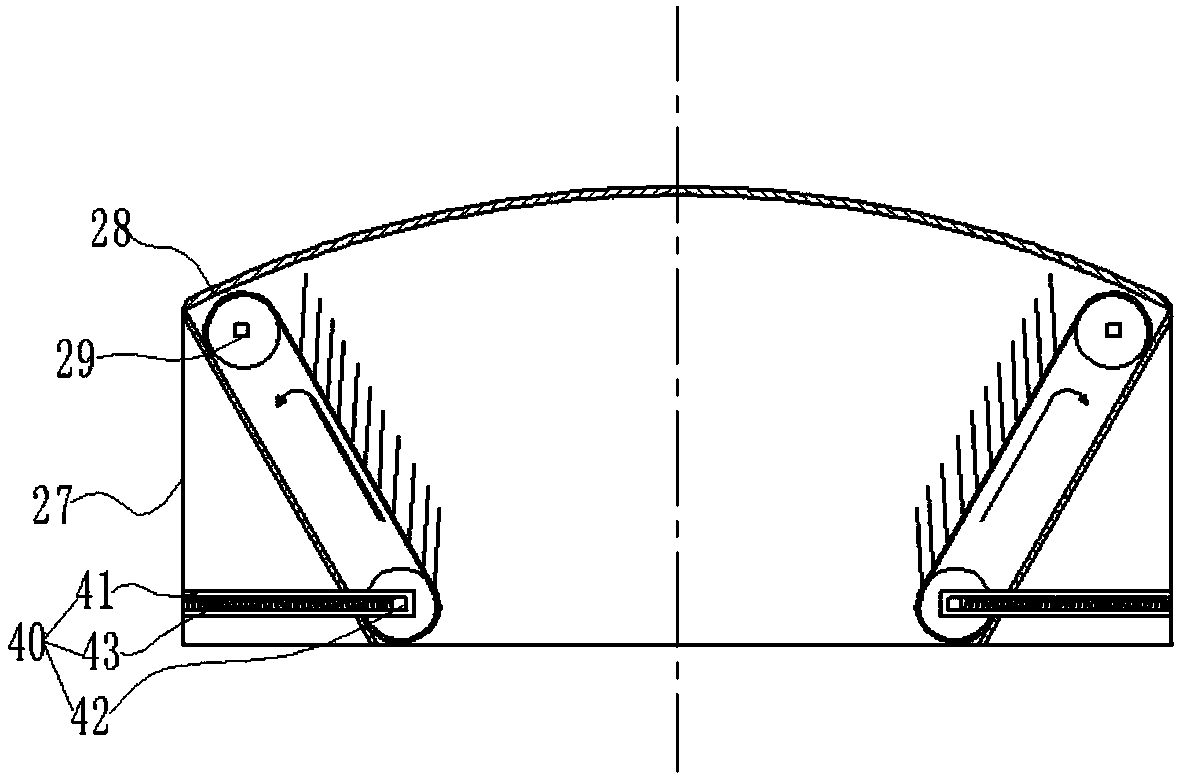

[0031] like figure 1 As shown, a multi-angle crushing mechanism for a glass pulverizer includes a crushing chamber 10 for crushing waste glass; the upper end of the crushing chamber 10 is provided with a feed chamber 20 for separating stains and waste glass; waste glass passes through After being processed in the feeding chamber 20, it enters the crushing chamber 10 for crushing treatment, and the particles formed after passing the crushing pass through the sieve holes on the lower end surface of the crushing chamber 10, and are washed in the cleaning mechanism 30.

[0032] In the prior art, because glass is used in a wide range, the types of waste glass recycling are very messy, with different sizes and shapes, and because the glass is relatively sharp, it is easy to scratch people, so the need to crush the glass is increased. Difficulty, the pulverizing effect of the existing pulverizer is not good enough, and it is impossible to use the waste glass as the aggregate of concr...

Embodiment 2

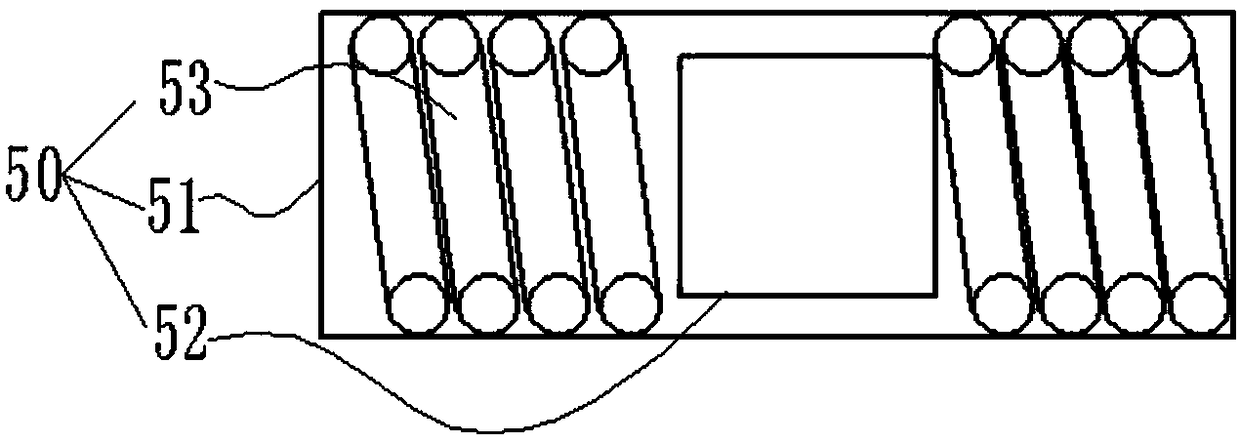

[0038] As shown in the figure, the structure of this embodiment is basically the same as the structure of Embodiment 1, and the similarities will not be repeated. The difference is that: figure 1 As shown, the cleaning mechanism 30 includes a cleaning chamber arranged at the lower end of the crushing chamber 10. The center of the lower end surface of the lower crushing plate 13 is fixedly connected with one end of the drive rod 31. Also be provided with servomotor, servomotor external power supply, also be provided with pendulum 32 on the peripheral surface of driving rod 31, like this, in the present invention, be provided with cleaning mechanism 30 at the lower end of pulverizing chamber 10, the sieve that is provided with on lower pulverizing plate 13 The hole can screen out the particles that have been crushed and enter the cleaning mechanism 30 for cleaning. Since the lower crushing plate 13 is rotated, and the rotational force is provided by a servo motor connected to the...

Embodiment 3

[0040] like figure 1 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, and the similarities will not be repeated. The difference is that: the left side of the cleaning mechanism 30 is also provided with a replacement tank 33 for replacing water, and the upper end of the replacement tank 33 is A water inlet 34 is provided, a water outlet 35 is provided on one side of the lower end of the replacement tank 33, a spherical float 36 is also provided in the replacement tank 33, and a scale 37 is arranged on the upper end of the spherical float 36, and the upper end of the scale 37 passes through the replacement tank 33 The through hole at the upper end passes through, and the right side of the cleaning mechanism 30 is provided with an opening. The lower end of the opening is rotated by a return spring to be provided with a valve 38. The valve 38 is a normally closed valve. , the other end of the rope 39 is fixedly connected with the ball float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com