Anti-discoloration treatment method for stainless steel work piece

A processing method and technology of stainless steel, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as unfavorable production and use, increase in cost, etc., and achieve less corrosion weight loss, high temperature resistance and discoloration ability. High temperature resistance to discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

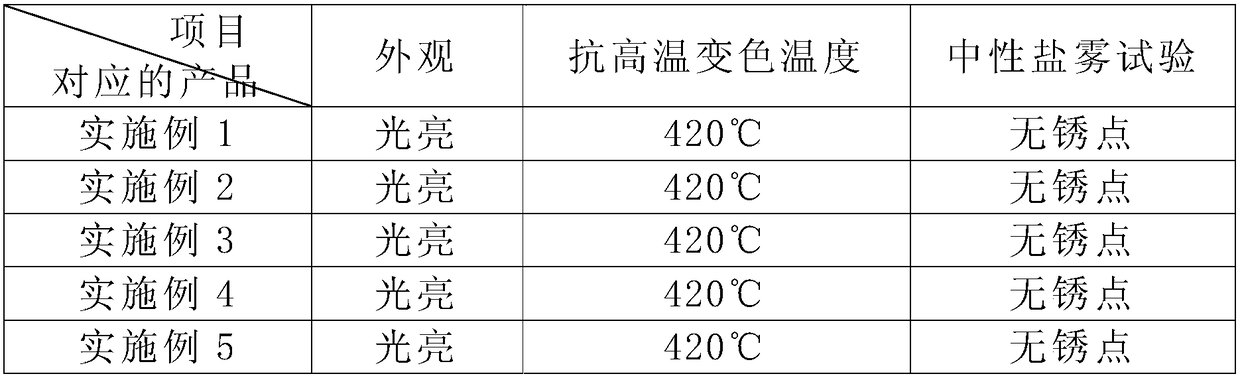

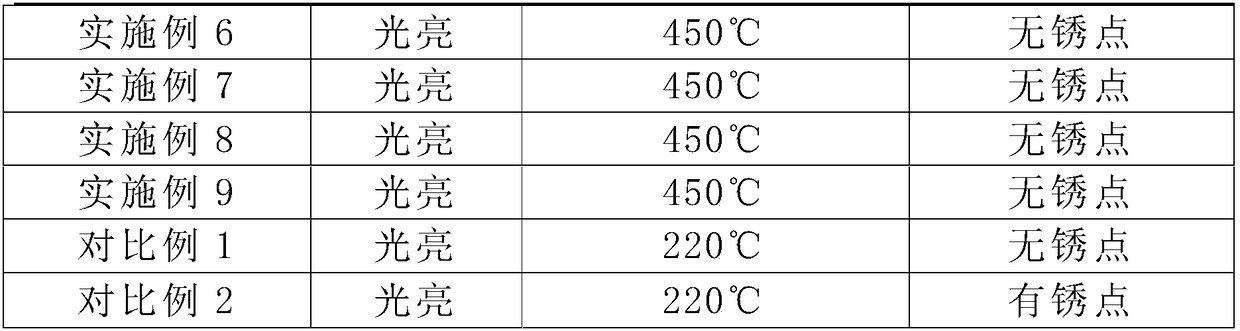

Embodiment 1

[0036] In this example, the stainless steel workpiece processed by 340 stainless steel is used, and the pre-processed stainless steel cookware workpiece is placed in a drying tunnel or oven with a temperature controlled at 260-300 ° C, and is subjected to high-temperature oxidation baking in an air atmosphere Treat for 60 minutes to form an oxide film on the surface of the stainless steel. The formed oxide film will form a light yellow-brown-brown oxide film color change state during the treatment process. After the high-temperature baking treatment, immerse the stainless steel cookware workpiece that has undergone high-temperature discoloration into sulfuric acid The chemical etching treatment is carried out in the aqueous solution, and the hydrogen ions in the acidic solution react with the oxides in the oxide film to remove the oxides in the oxide film, so as to restore the original color of the stainless steel workpiece without basically damaging the surface. The pH value o...

Embodiment 2

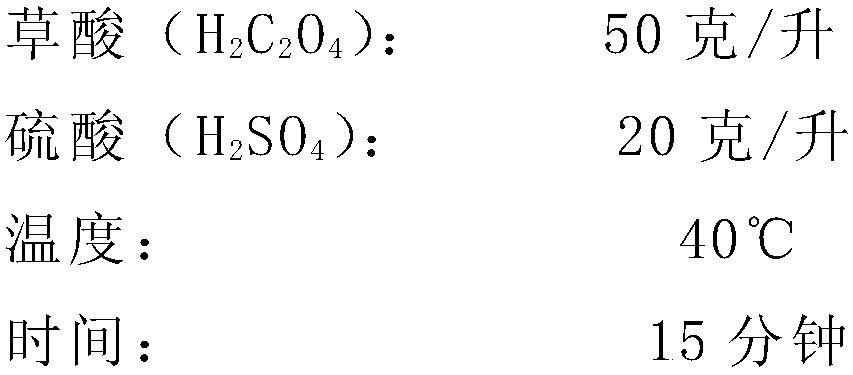

[0042] In this example, a stainless steel workpiece processed from 340 stainless steel is used, and the pre-processed stainless steel cookware workpiece is placed in a drying tunnel or oven with a temperature controlled at 310-400°C, and is subjected to high-temperature oxidation baking in an air atmosphere Treat for 20 minutes to form an oxide film on the surface of the stainless steel. The formed oxide film will form a light yellow-brown-brown oxide film color change state during the treatment process. After the high-temperature baking treatment, immerse the stainless steel cookware workpiece that has undergone high-temperature discoloration into oxalic acid The aqueous solution is chemically etched to remove surface oxides and achieve the effect of restoring the original color of stainless steel workpieces without basically damaging the surface. The pH value of the acidic solution here is controlled below 3, and the specific conditions of the above-mentioned chemical etching...

Embodiment 3

[0048] In this embodiment, the stainless steel workpiece processed by 340 stainless steel is used, and the pre-treated stainless steel cookware workpiece is placed in a drying tunnel or oven with a temperature controlled at 500 ° C, and is subjected to high-temperature oxidation baking treatment in an air atmosphere. Minutes to form an oxide film on the surface of the stainless steel, the formed oxide film will form a light yellow-brown-brown oxide film color change state during the treatment process, after the high-temperature baking treatment, immerse the stainless steel cookware workpiece that has undergone high-temperature discoloration into the citric acid aqueous solution Carry out chemical etching treatment, the specific conditions of above-mentioned chemical etching treatment are as follows:

[0049] Citric acid (C 6 h 8 o 7 ): 50 g / l

[0050] Temperature: 60°C

[0051] Time: 10 minutes

[0052] After the chemical etching treatment is finished, the subsequent clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com