Water jet deburring surface finishing equipment

A water jet and deburring technology, used in metal processing equipment, abrasive jet machine tools, abrasive feeding devices, etc., can solve problems such as difficult to control machining accuracy, high labor intensity, rework, etc., to eliminate hidden quality problems and improve technology. The effect of level and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

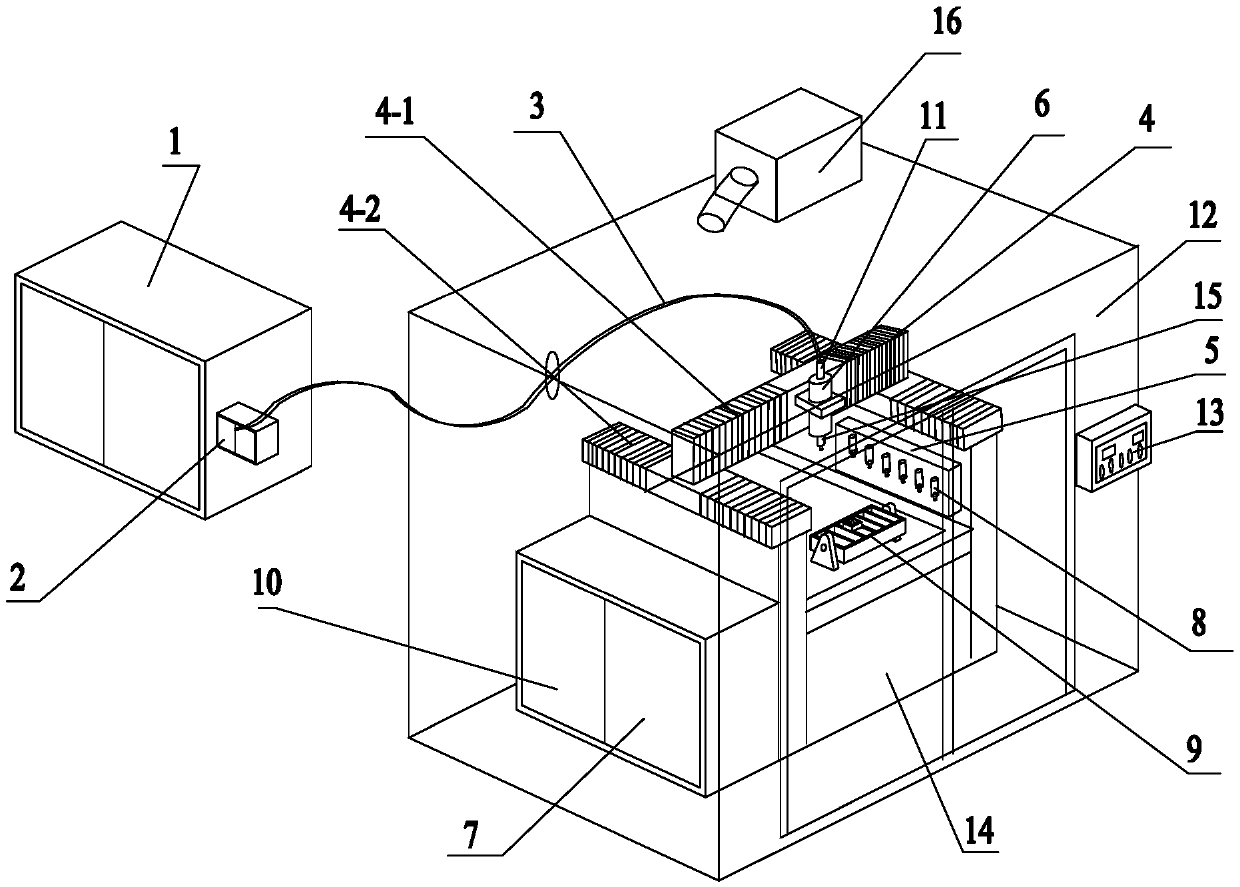

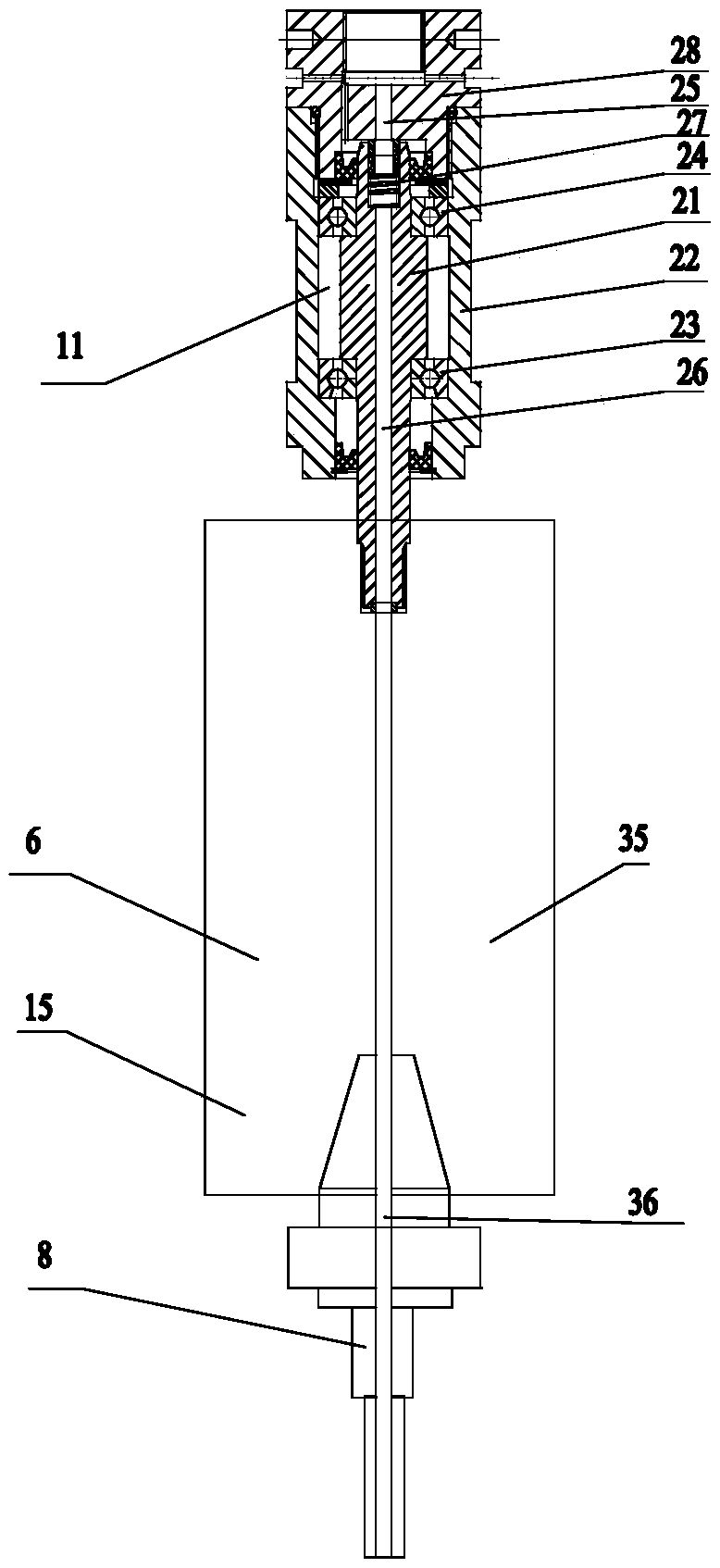

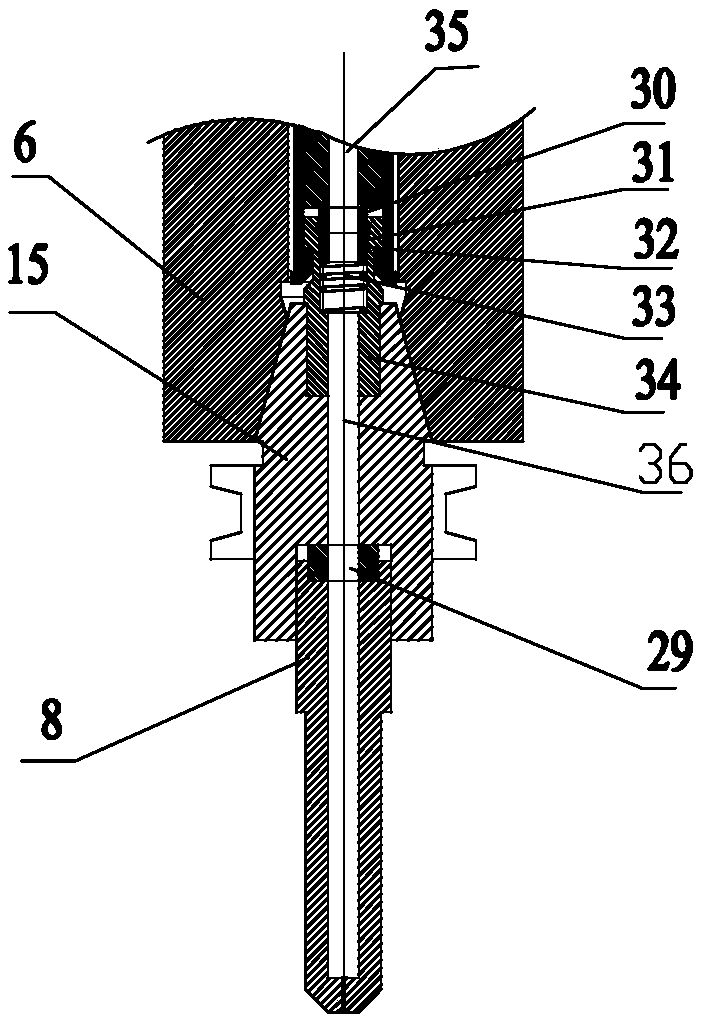

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Figure 1~3 Among them, including high-pressure water generator 1, pressure regulator 2, high-pressure pipeline 3, machining center actuator 4, beam 4-1, longitudinal beam 4-2, tool changing platform 5, central water outlet spindle device 6, oil-water separator 7. High-pressure water jet nozzle 8, workpiece clamping platform 9, filter 10, rotary joint 11, protective cover 12, control switch 13, collection box 14, high-pressure water jet handle 15, mist absorber 16, 80-degree double sides Rotating jet nozzle, fan-shaped jet nozzle, straight hole jet nozzle, 90-degree one-way side jet nozzle, rotating shaft 21, bearing seat 22, lower bearing 23, upper bearing 24, liquid inlet hole 25, inner hole of the rotating shaft 26, Elastic sealing ring 27, high-pressure water inlet joint 28, main hole 29, high-pressure sealing ring 30, elastic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com