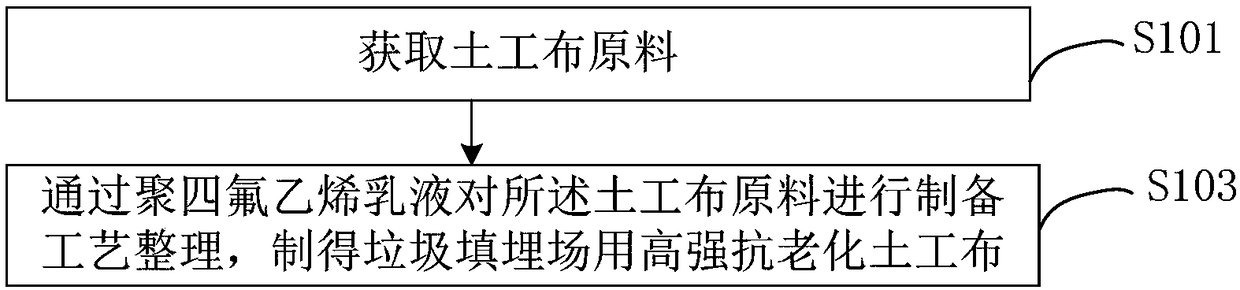

Geotextile production method

A production method and technology of geotextiles, applied in textiles and papermaking, fiber treatment, light-resistant fibers, etc., can solve the problems of cumbersome production process of geotextiles, and achieve the improvement of anti-ultraviolet mechanical properties, strength, and thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

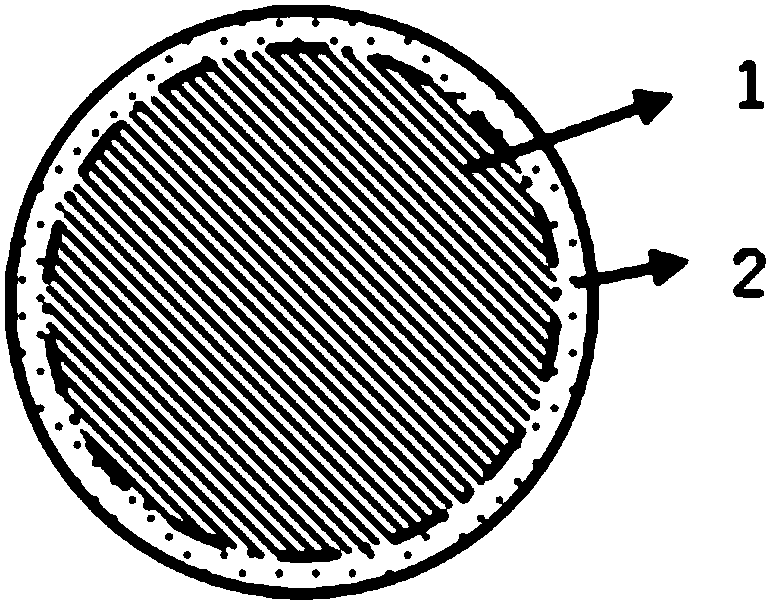

[0039] The invention discloses a production method of a high-strength anti-aging geotextile for landfills, which is prepared by impregnating polypropylene filament fibers with polytetrafluoroethylene emulsion or coating polypropylene needle felt.

[0040] The dipping process includes: placing the polytetrafluoroethylene emulsion in the stock tank, the melt-extruded polypropylene filament fiber passes through the stock tank filled with the polytetrafluoroethylene emulsion after preliminary drafting, the dynamic advance dipping time is 3min, and the drying temperature is 110°C. ℃;

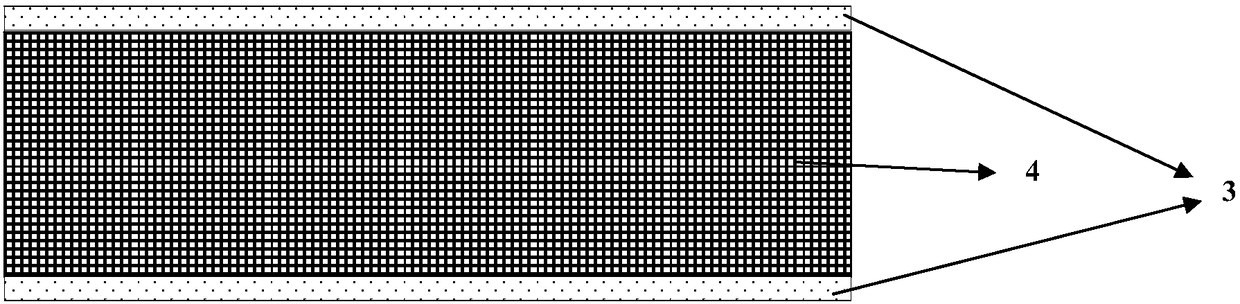

[0041] The coating process includes: placing the polytetrafluoroethylene emulsion in the slurry tank, the polypropylene geotextile passes through the liquid surface of the slurry tank filled with polytetrafluoroethylene at a low speed, and the slurry is fully brushed on the geotextile horizontally and vertically by multiple pairs of brushes. Use a brush to cross-coat the front and back 5 times in a h...

Embodiment 2

[0043] The invention discloses a production method of a high-strength anti-aging geotextile for landfills, which is prepared by impregnating polypropylene filament fibers with polytetrafluoroethylene emulsion or coating polypropylene needle felt.

[0044] The dipping process includes: placing the polytetrafluoroethylene emulsion in the stock tank, the melt-extruded polypropylene filament fiber passes through the stock tank filled with the polytetrafluoroethylene emulsion after preliminary drafting, the dynamic advance dipping time is 3 minutes, and the drying temperature is 130 ℃;

[0045]The coating process includes: placing the polytetrafluoroethylene emulsion in the slurry tank, the polypropylene geotextile passes through the liquid surface of the slurry tank filled with polytetrafluoroethylene at a low speed, and the slurry is fully brushed on the geotextile horizontally and vertically by multiple pairs of brushes. Use a brush to cross the front and back 5 times in a horiz...

Embodiment 3

[0047] The invention discloses a production method of a high-strength anti-aging geotextile for landfills, which is prepared by impregnating polypropylene filament fibers with polytetrafluoroethylene emulsion or coating polypropylene needle felt.

[0048] The dipping process includes: placing the polytetrafluoroethylene emulsion in the stock tank, the melt-extruded polypropylene filament fiber passes through the stock tank filled with the polytetrafluoroethylene emulsion after preliminary drafting, the dynamic advance dipping time is 3min, and the drying temperature is 150°C. ℃;

[0049] The coating process includes: placing the polytetrafluoroethylene emulsion in the slurry tank, the polypropylene geotextile passes through the liquid surface of the slurry tank filled with polytetrafluoroethylene at a low speed, and the slurry is fully brushed on the geotextile horizontally and vertically by multiple pairs of brushes. Use a brush to cross-coat the front and back 5 times in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com