Waterproof system for road-tunnel-corrugated-steel primary support structure

A technology for primary support and road tunnels, applied in the direction of tunnels, tunnel linings, drainage, etc., can solve problems such as damage to tunnel linings, silting, and reduced drainage effects, and achieve the goal of improving waterproofing ability, improving waterproofing ability, and economical and efficient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

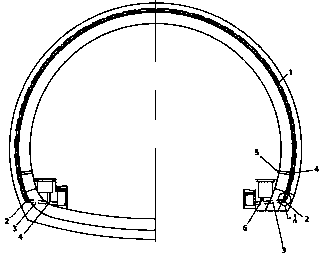

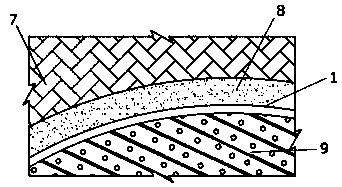

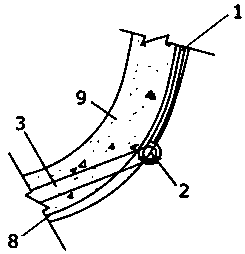

[0025] refer to Figure 1-6 As shown, the present invention provides a waterproof system for the primary support structure of corrugated steel in highway tunnels. A closed space can be formed between the surrounding rock and the corrugated steel plate primary lining 8, and mortar is filled in the closed space. Since the corrugated steel is a continuous and sealed structure as the primary support, the primary support structure itself can be used as the waterproof system. The first waterproof line, a rubber waterstop 11 is set between two adjacent corrugated steel plate linings 8 and connected by bolts 12 to prevent water leakage in the gap between the two corrugated steel plate linings 8, forming a The second waterproof line of the system, and the inner side of the corrugated steel plate primary lining 8 is provided with an Ω-shaped semicircular drainage pipe 1, and the Ω-shaped semicircular drainage pipe 1 is covered with a geotextile to make it permeable and block solid parti...

Embodiment 2

[0027] On the basis of the above-mentioned embodiments, the annular drainage channels are arranged at intervals along the direction of the tunnel, and the interval of each segment of the annular drainage channels is 4-6m. In order to achieve better results for the annular drainage channels, the annular drainage channels are The layout interval shall be determined according to the strength grade of the surrounding rock.

Embodiment 3

[0029] On the basis of the above embodiments, in order to make the drain pipe have the characteristics of high pressure resistance, good toughness and long life, the longitudinal drain pipe 2 and the horizontal drain pipe 3 are both HDPE corrugated pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com