Electric control automatic speed changing main reducing gear

A technology of automatic transmission and main reducer, which is applied in the direction of vehicle gearboxes, transmission components, control devices, etc., can solve the problems of increasing the cost of electric vehicles, increasing the complexity and weight of the drive system, and achieving simple structure, low cost, and geographical coverage. Applicable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

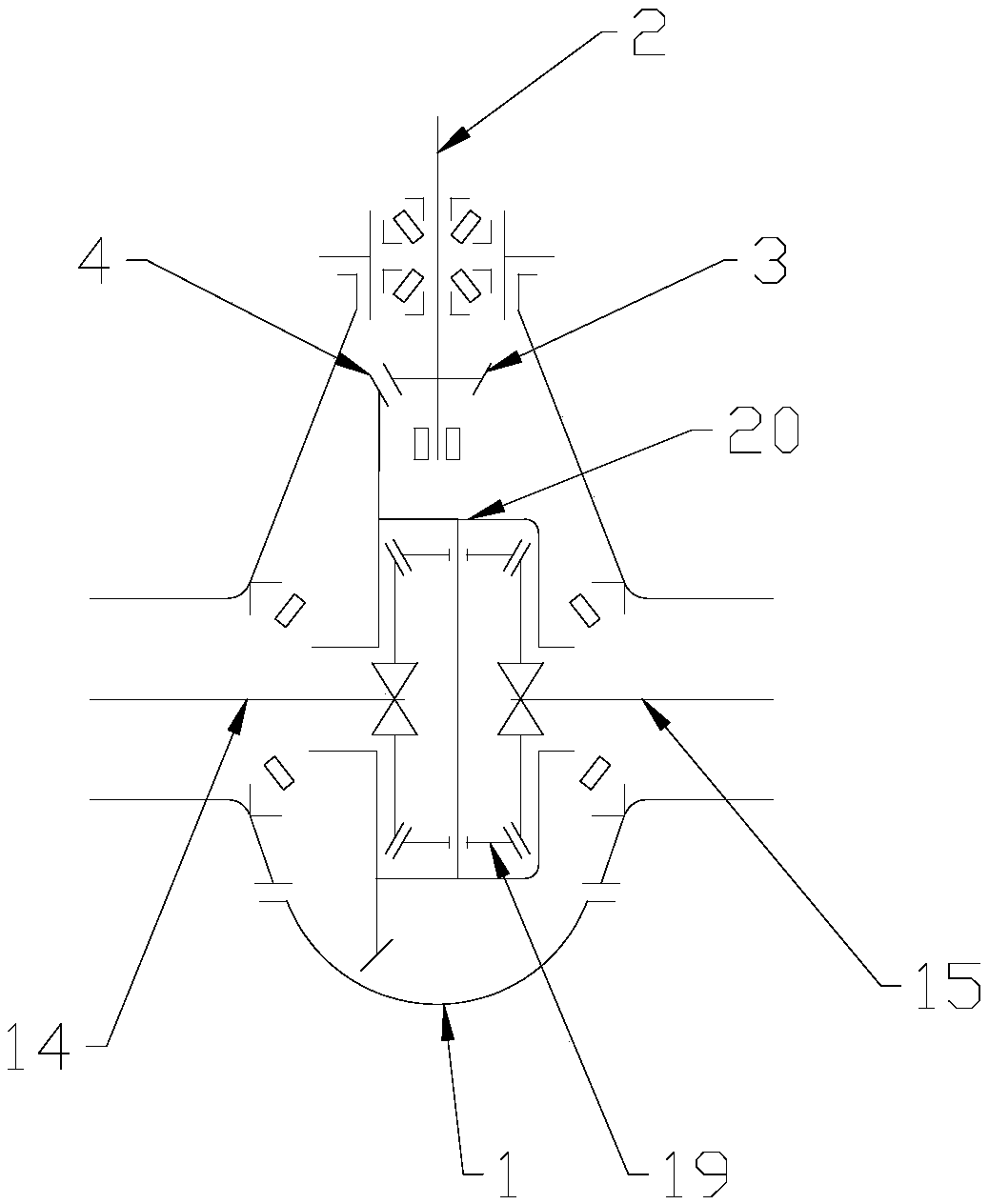

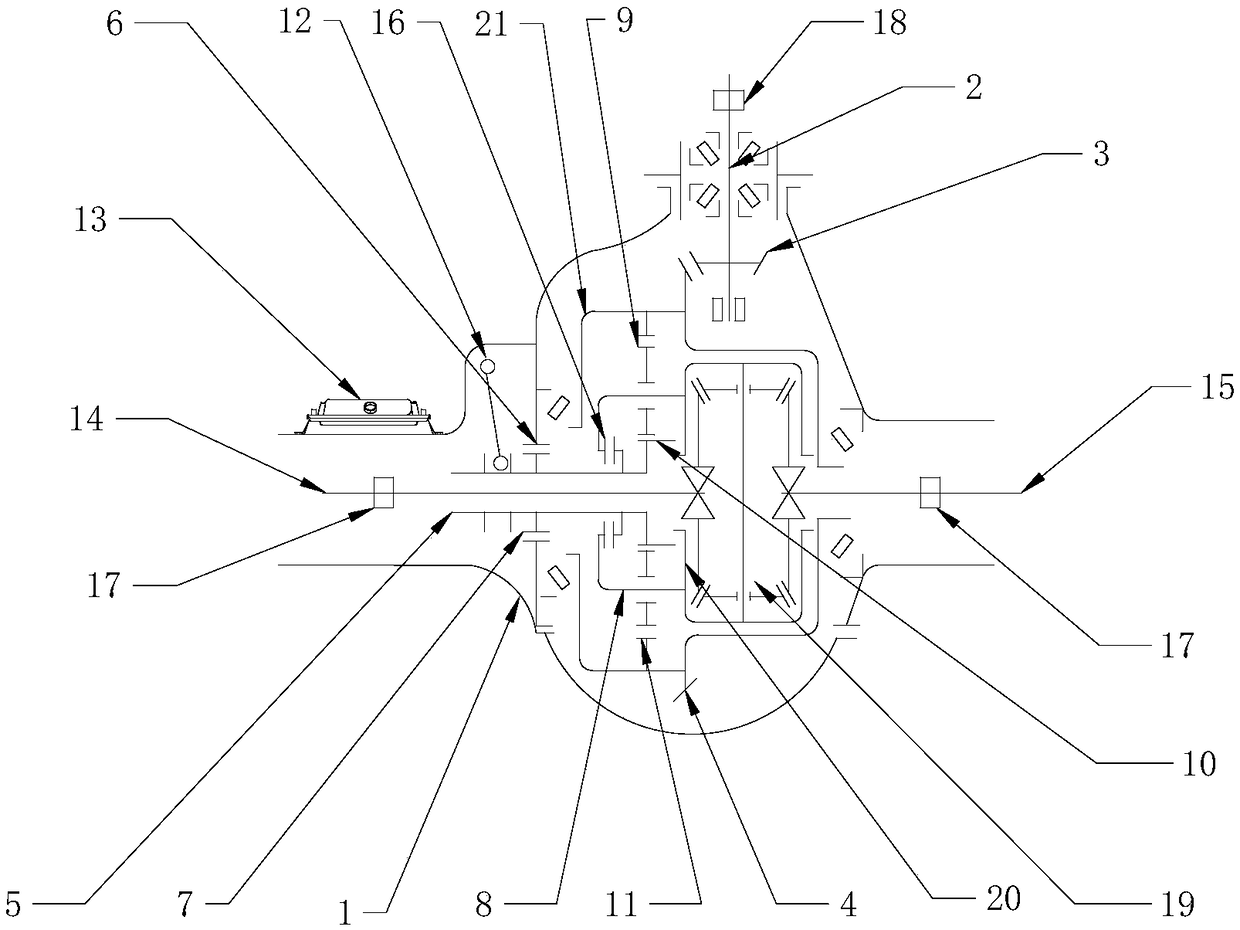

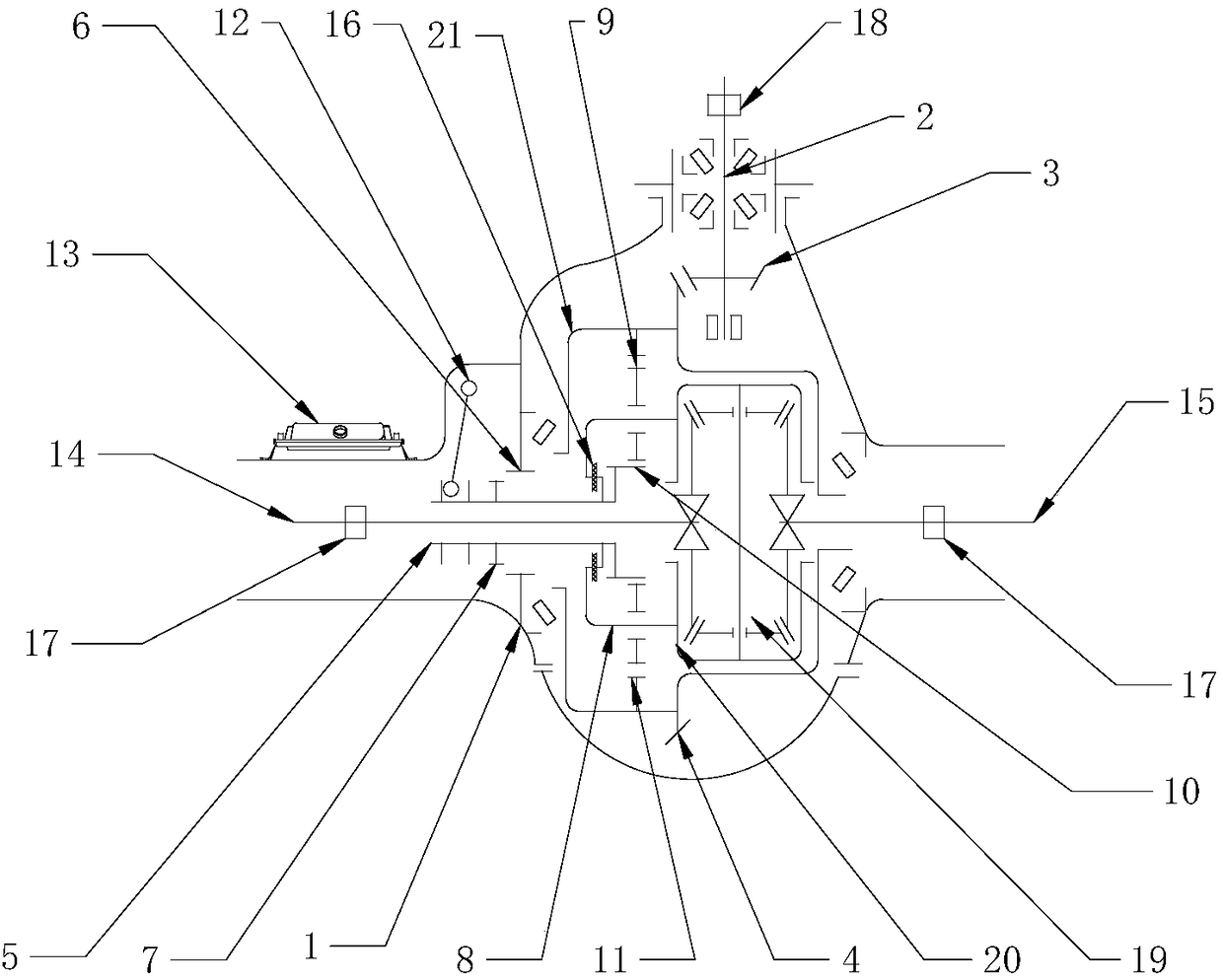

[0030] combine Figure 1 to Figure 3 , to describe this embodiment in detail.

[0031] The existing final reducer includes a housing 1, an input shaft 2, a driving bevel gear 3, a driven bevel gear 4, a first output shaft 14 and a second output shaft 15, and the differential housing 20 and the driven bevel gear 4 can be The phases are fixedly connected, the input shaft 2 transmits power to the driven bevel gear 4 through the driving bevel gear 3, and the driven bevel gear 4 drives the reducer for power transmission. The direct drive drive system has simple structure, low cost and good reliability. However, due to the non-adjustable speed ratio of the direct-drive drive system, the electric vehicle using the direct-drive drive system has problems such as insufficient vehicle climbing ability at low speeds, and high speed of the drive motor at high speeds, resulting in low motor efficiency and high noise. The power and economy cannot be balanced.

[0032] see figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com