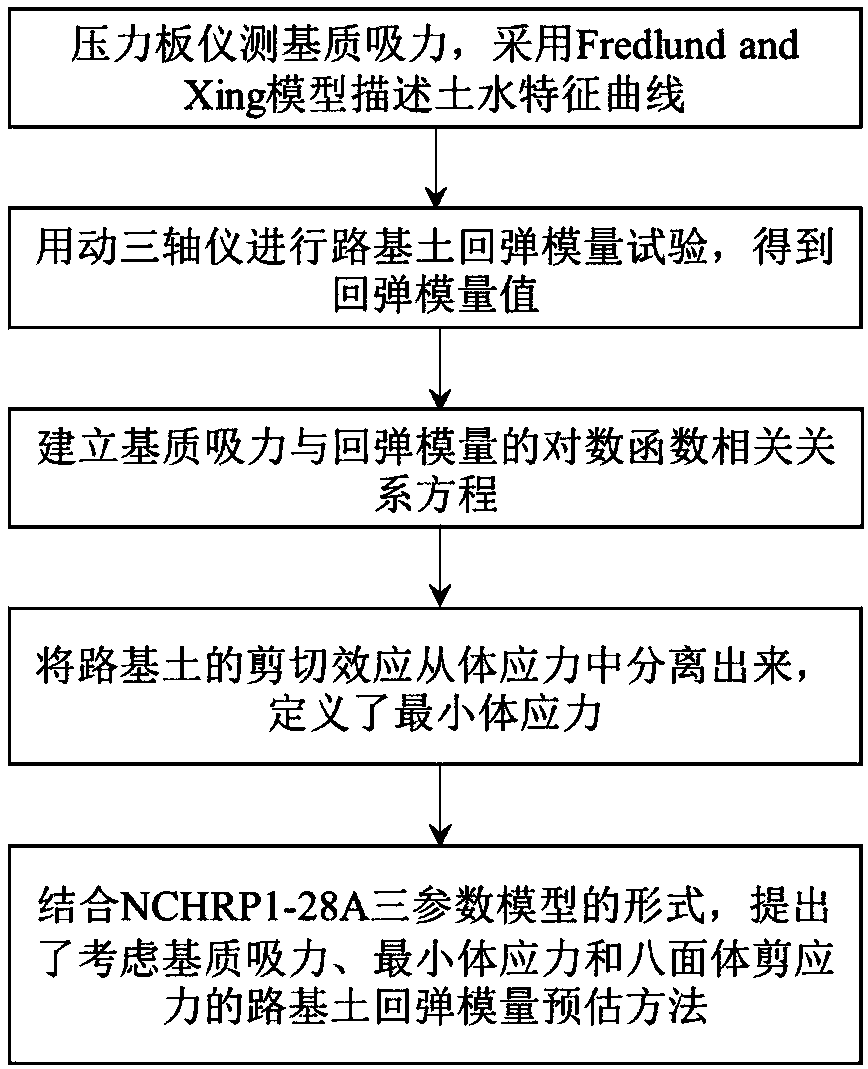

Dynamic subgrade soil resilience modulus prediction method based on matric suction and minimum body stress

A technology of matrix suction and resilience modulus, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the influence of the resilience modulus of subgrade soil moisture state that cannot be directly reflected, and restrict the estimation method of subgrade soil resilience modulus. problems such as promotion and application, difficulty in obtaining parameters, etc., to achieve the effect of easy promotion and application, simple structure and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

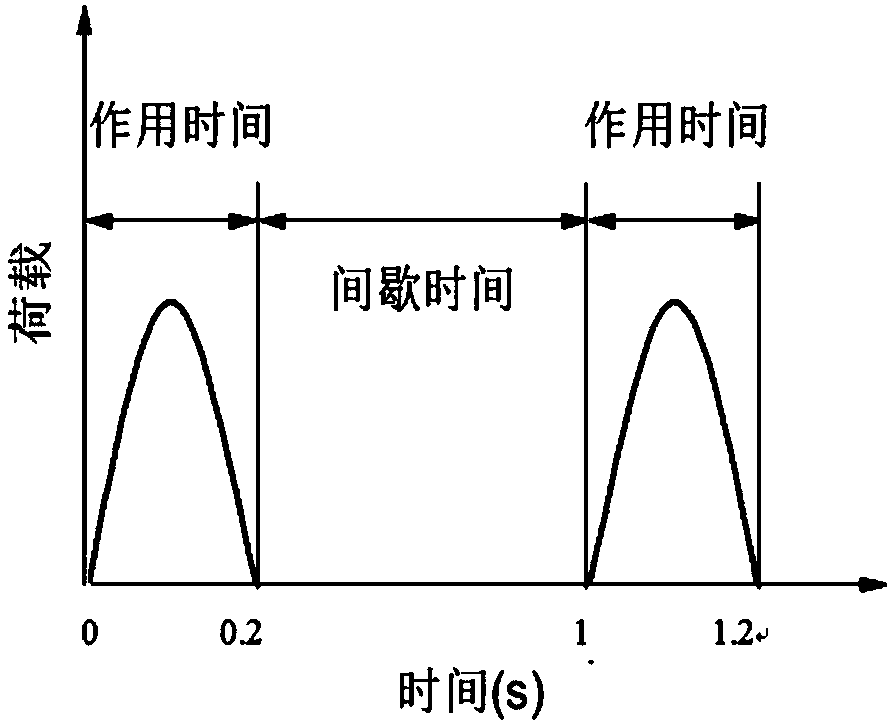

Method used

Image

Examples

Embodiment 1

[0055] Example demonstrates the specific implementation process of the present invention with high liquid limit clay, and Table 2 is a statistical table of basic physical parameters.

[0056] Table 2 Statistical table of basic physical parameters of high liquid limit clay

[0057]

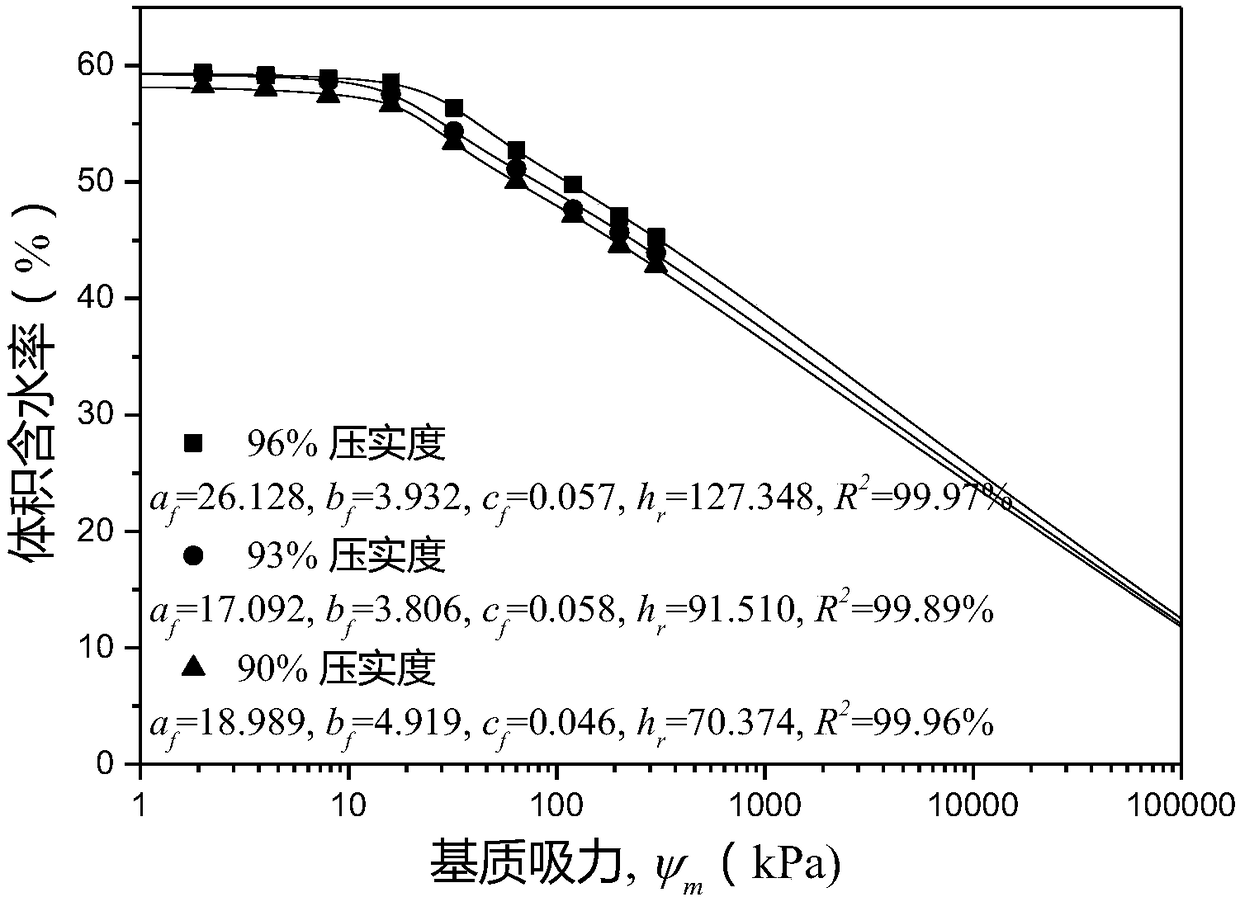

[0058] Step a: Make test pieces under 90%, 93%, and 96% compaction, and measure the matrix suction value of each test piece with a pressure plate meter. The test results are as follows image 3 shown.

[0059] The Fredlund and Xing model (as shown in formula (3)) was used to establish the soil-water characteristic curve of high liquid limit clay, and the model parameters under different compaction degrees were obtained, as shown in Table 3.

[0060]

[0061] where: θ w is the volume moisture content; θ s is the saturated volumetric water content; h is the matric suction; a f , b f , c f and h r is the model parameter.

[0062] Table 3 Fredlund and Xing model parameters

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com