Photoetching method and photoetching machine

A lithography machine and aperture technology, applied in the field of lithography, can solve the problem of low pattern contrast of dense patterns in lithography, and achieve the effects of solving low pattern contrast, improving performance and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

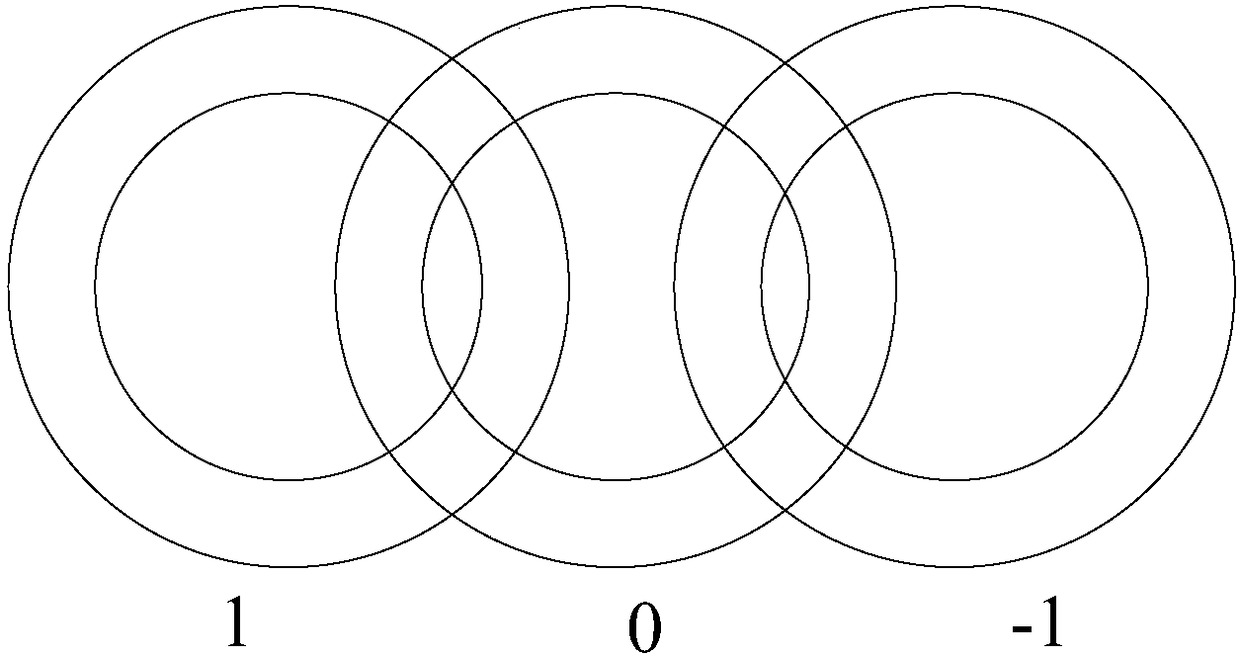

[0027] As mentioned above, existing photolithography suffers from low pattern contrast. To better explain the problem, refer to figure 1 The schematic diagram of the shape of the light source used for photolithography is shown.

[0028] like figure 1 As shown, the light emitted from the light source includes multi-level light after diffraction, such as 0-level light, 1-level light, 2-level light...etc. After filtering the light emitted by the light source with a diaphragm and an optical lens, the 0-order light and ±1-order light are reserved for photolithography.

[0029] It should be noted, figure 1 The two sides of the middle 0 aurora are graphics formed by 1st-level light and -1-level light, but the left and right positions of 1st-level light and -1-level light do not affect the actual lithography effect. This is artificial for easy understanding. Regulation. The reason is the same in the following description and examples.

[0030] figure 1 Shown are ring 0 and ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com