Structural crack automatic plotting and width precise measuring method and equipment

A crack width and detection method technology, which is applied in measurement devices, image data processing, instruments, etc., can solve problems such as inability to effectively distinguish cracks and noise interference, large error in calculating width of fine cracks, and large error in measuring crack width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

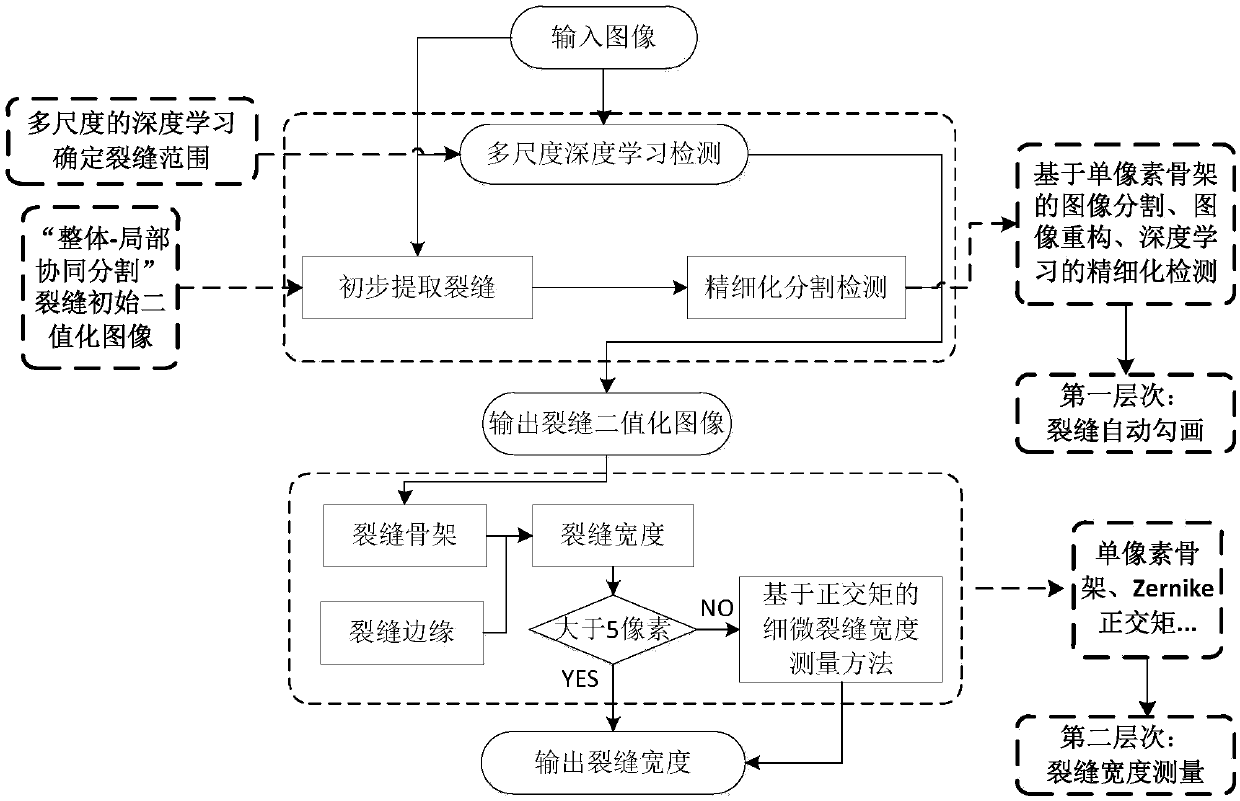

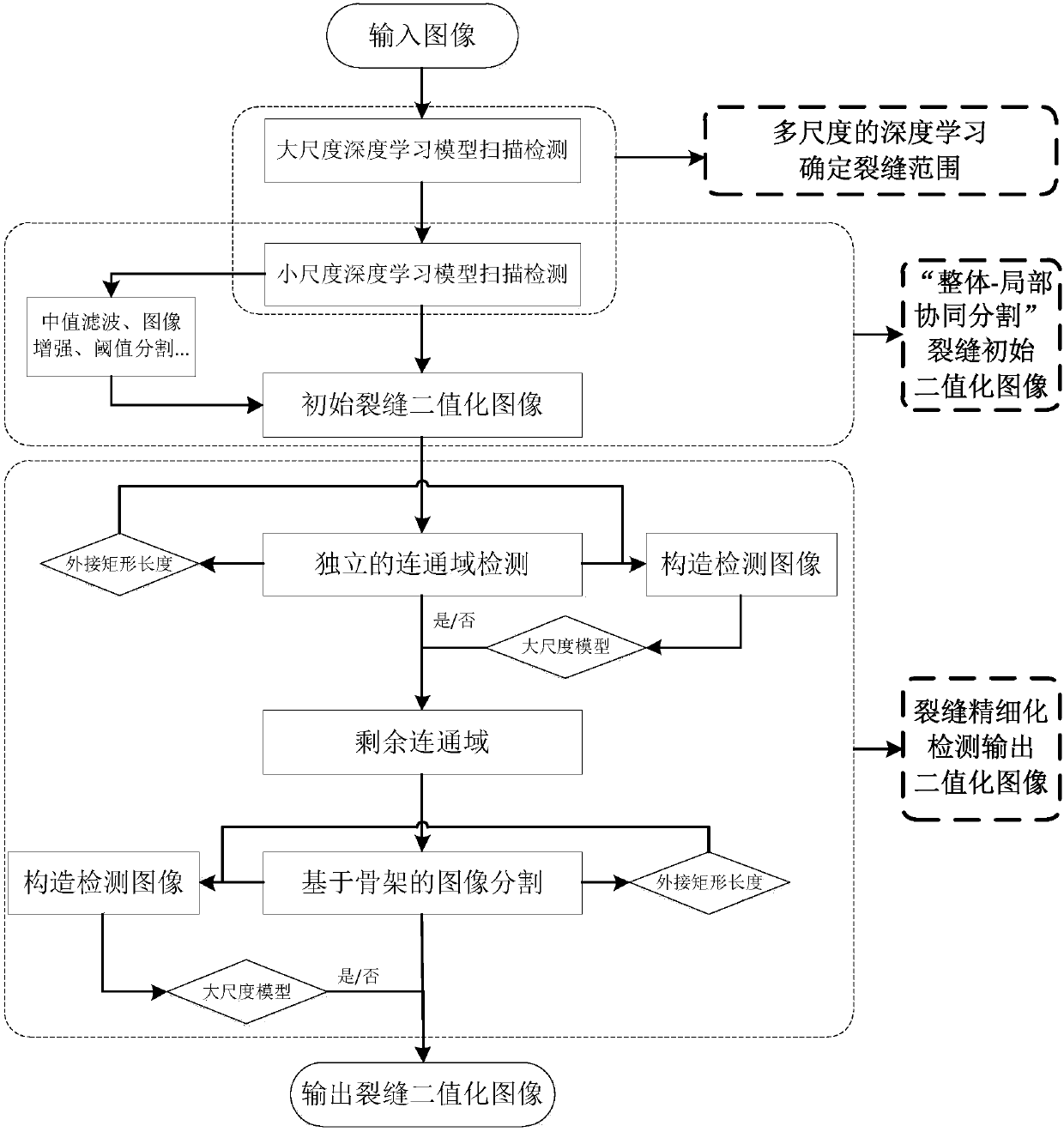

[0070] Embodiment 1: A kind of structural crack automatic drawing method, such as image 3 As shown, the description method includes the following steps, 1) a crack detection method based on multi-scale deep learning, using multi-scale deep learning to detect the range of cracks in the image to ensure that follow-up work does not miss crack information; 2) based on The "overall-local collaborative segmentation" preliminary crack extraction method based on deep learning, median filtering and Hessian matrix linear enhancement ensures that the extracted results include both wide cracks and fine cracks in the image, ensuring a high recall rate of detection results ; 3) The fine crack detection method based on deep learning, image segmentation, and image reconstruction can effectively eliminate noise interference in the results and ensure high accuracy and high precision of the detection results. The step 1) multi-scale depth Learn how to detect cracks, specifically as follows: the...

Embodiment 2

[0096] Embodiment 2: A kind of accurate measurement method of crack width based on single-pixel crack skeleton and Zernike orthogonal moment, the traditional method of calculating crack width is to calculate the method of "counting pixels" of the distance between two pixel points, for 5 The calculation effect of cracks with a width below one pixel is poor. The present invention proposes a crack width calculation method based on a single-pixel skeleton and Zernike orthogonal moments for cracks less than 5 pixels in an image, such as Image 6 shown.

[0097] The crack width calculation method based on the single-pixel skeleton and Zernike orthogonal moments is characterized in that: the single-pixel skeleton is used to determine the rotation angle of the image, and the image at this point is rotated, symmetrical, and mirrored into two symmetrical images about the y-coordinate axis , use the orthogonal moment template to calculate the second-order orthogonal moments A of the two ...

Embodiment 3

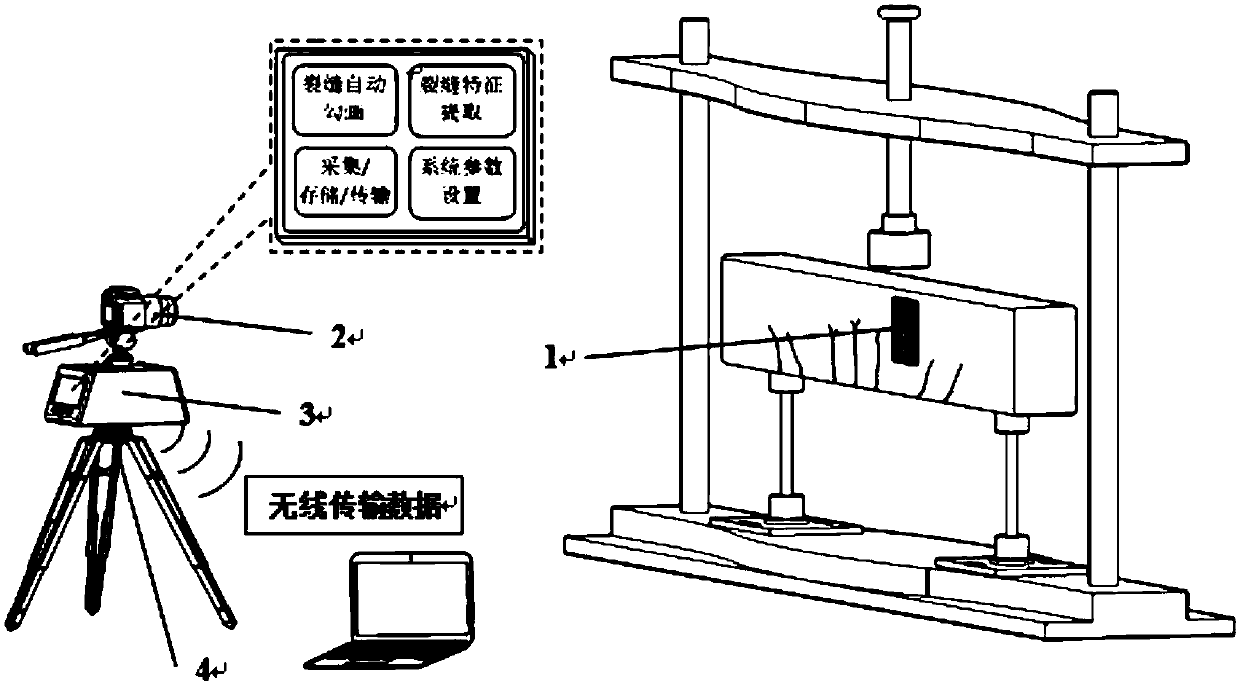

[0102] Embodiment 3: A kind of laboratory concrete specimen crack automatic drawing and width measuring equipment, such as figure 1 As shown, it includes an image calibration module 1, an image acquisition module 2, an image processing system 3, and a camera bracket 4, wherein the image processing system 3 is embedded with an automatic crack delineation algorithm module, a crack feature analysis algorithm module, a calculation result storage module and a wireless transmission module;

[0103] Automatic drawing of structural cracks and precise width measurement equipment can realize rapid and automatic drawing of cracks on the surface of structures and accurately measure the width of cracks.

[0104] The image calibration module 1 is used to correct the camera posture and calculate the resolution of the image, and paste several checkerboards of known size manually printed on the surface of the concrete specimen; the image acquisition module 2 is composed of a single-lens refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com