Current-limiting reactor of three-phase wire shared magnetic ring

A technology of current-limiting reactors and phase conductors, used in circuits, electrical components, transformer/inductor magnetic cores, etc. Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

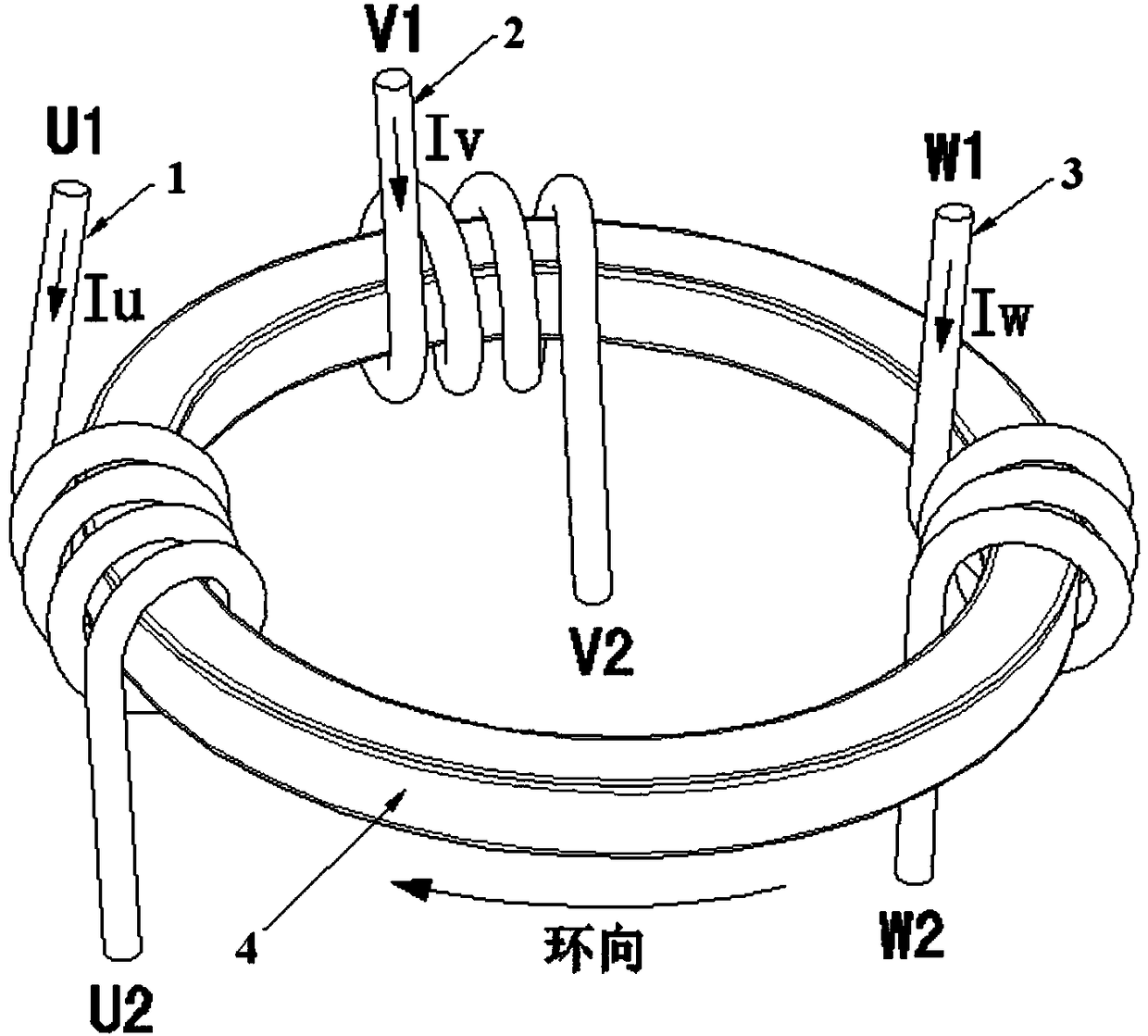

[0030] In this example, if image 3 As shown, three insulated wires 1, 2, and 3 with a length of 590mm and a wire diameter of 8 square millimeters are respectively wound on an amorphous magnetic ring 4 of 57×32×20 mm for 4 turns to form a A current-limiting reactor for three-phase conductors sharing a magnetic ring. The wire 1 is connected to the U terminal, the current Iu flows from the U1 terminal to the U2 terminal, and flows counterclockwise around the ring direction of the amorphous magnetic ring 4; the wire 2 is connected to the V terminal, and the current Iv flows from the V1 terminal to the V2 terminal, around The circumferential direction of the amorphous magnetic ring 4 flows in a clockwise direction; the wire 3 is connected to the W terminal, and the current Iw flows from the W1 terminal to the W2 terminal, and the circumferential direction around the amorphous magnetic ring 4 flows in a clockwise direction. The current-limiting reactor of the three-phase wires sha...

Embodiment 2

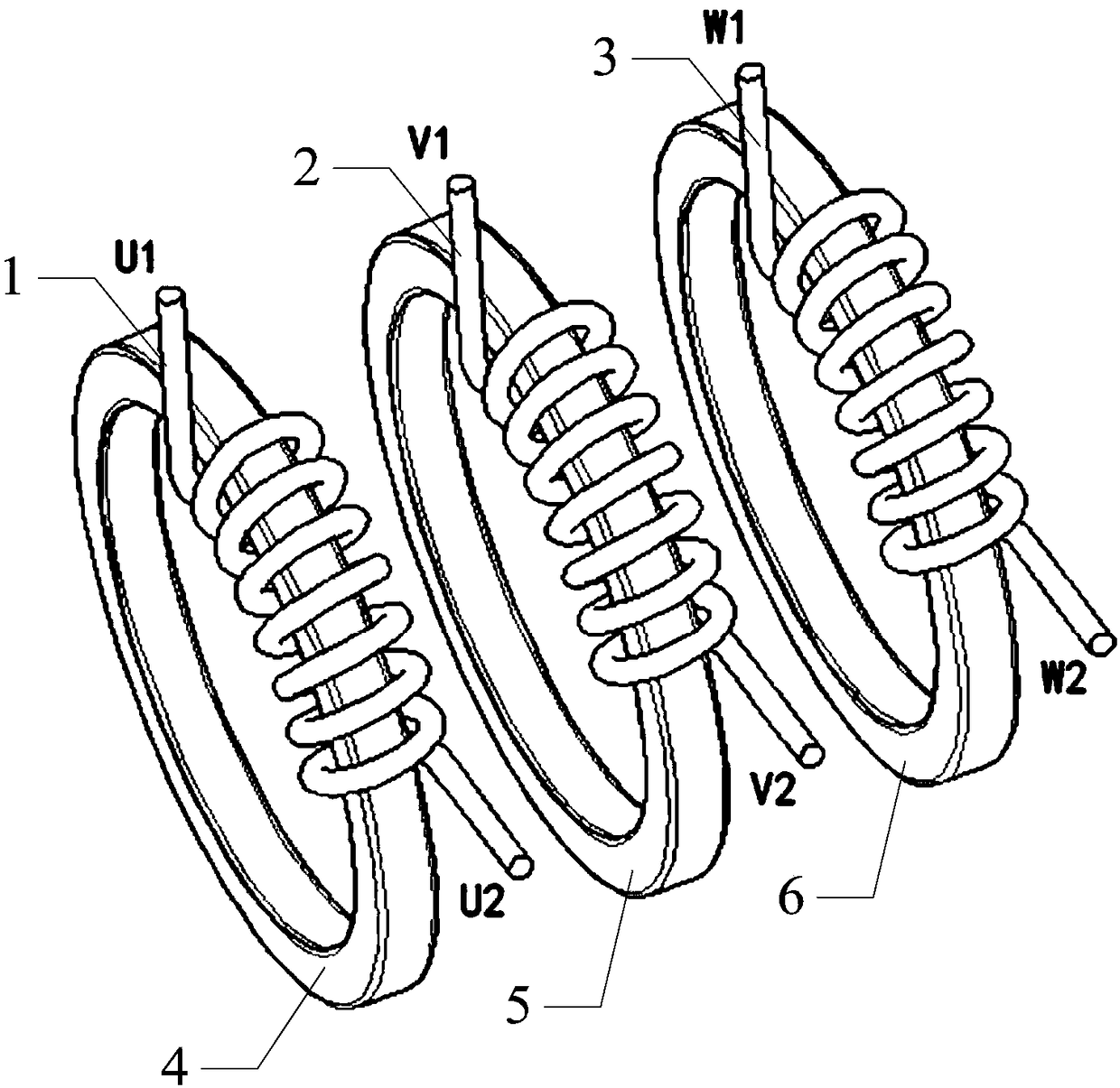

[0035] In another embodiment, such as Figure 4 As shown, three insulated wires 1, 2 and 3 with a length of 590 mm and a wire diameter of 8 square millimeters are respectively placed in a group of amorphous magnetic rings of 50 × 25 × 10 mm (composed of magnetic rings 4 and magnetic rings of the same specification) The ring 5 is superimposed) and 4 coils are wound on the top to form a current-limiting reactor in which the three-phase wires share the magnetic ring. The wire 1 is connected to the U terminal, the current Iu flows from the U1 terminal to the U2 terminal, and flows counterclockwise around the ring direction of the amorphous magnetic ring group; the wire 2 is connected to the V terminal, and the current Iv flows from the V1 terminal to the V2 terminal, around the The ring direction of the amorphous magnetic ring group flows clockwise; the wire 3 is connected to the W terminal, the current Iw flows from the W1 end to the W2 end, and the ring direction around the amor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com