Stable white-light organic thin-film electroluminescent device with bipolar mixed spacer layers, and preparation method thereof

A technology for electroluminescent devices and organic thin films, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as increased manufacturing costs, unfavorable industrial manufacturing and wide application, and complicated preparation processes, and achieves Convenient operation, easy control, uniform effect of luminous spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

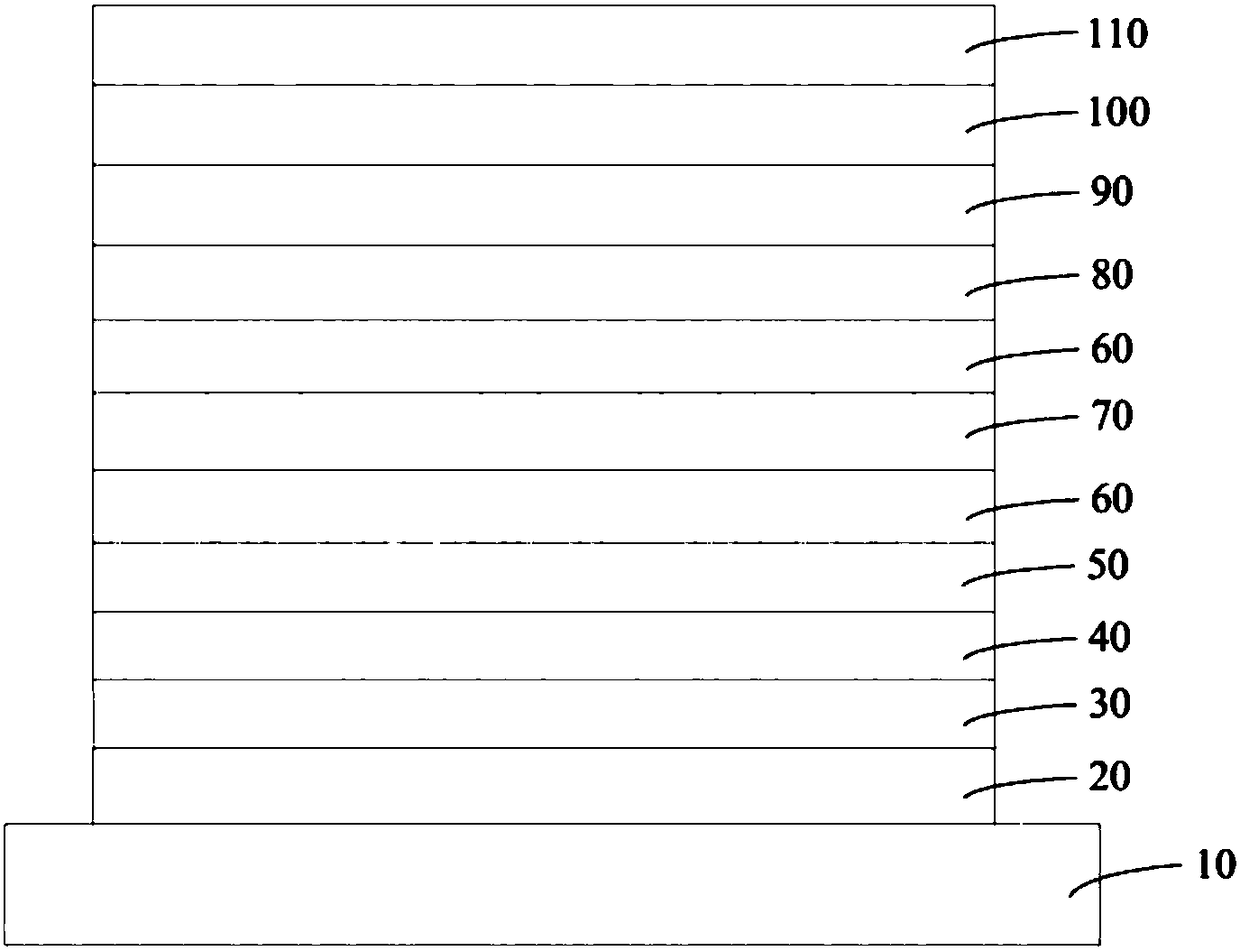

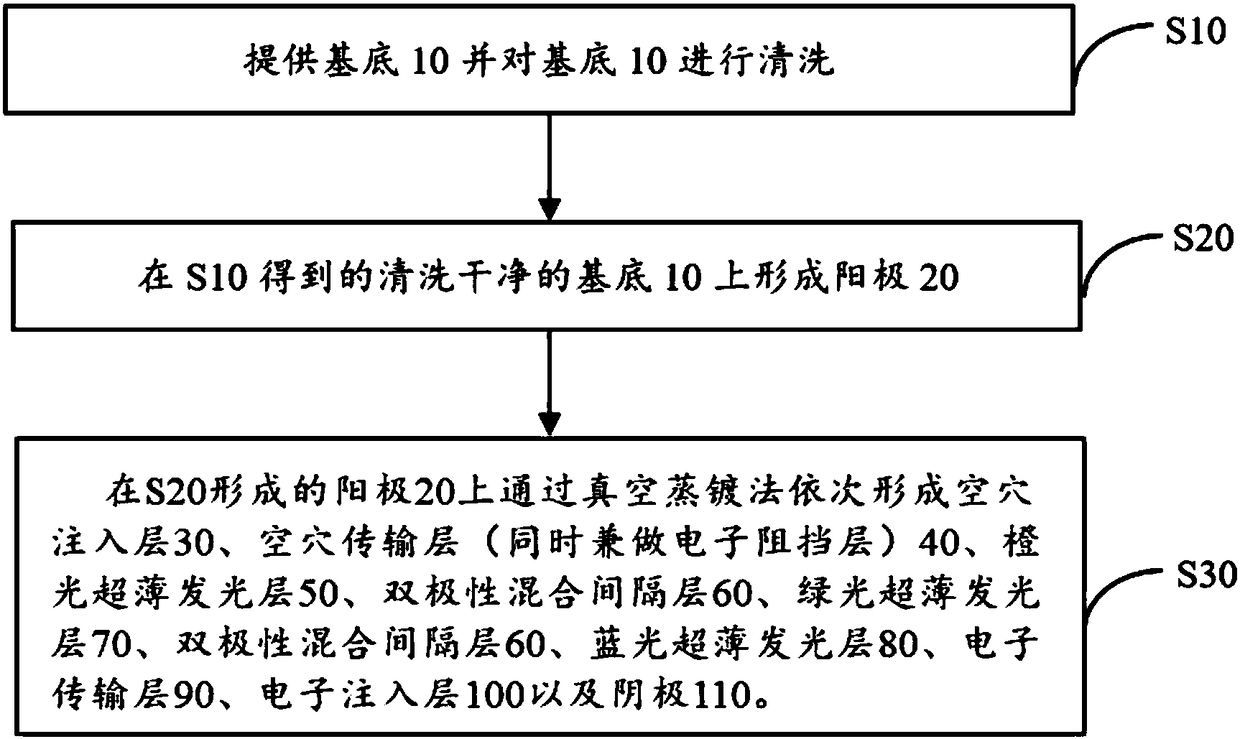

[0031] In this example, see figure 1 and figure 2 , a stable white light organic thin film electroluminescent device with a bipolar mixed spacer layer, comprising a substrate 10, an anode 20, a hole injection layer 30, a hole transport layer 40, an orange light ultrathin light emitting layer 50, The bipolar mixed spacer layer 60 on the front side, the green light ultra-thin light-emitting layer 70, the bipolar mixed spacer layer 60 on the back side, the blue light ultra-thin light-emitting layer 80, the electron transport layer 90, the electron injection layer 100 and the cathode 110; Wherein the hole transport layer 40 doubles as an electron blocking layer at the same time; the orange light ultra-thin light-emitting layer 50, the bipolar mixed spacer layer 60 on the front side, the green light ultra-thin light-emitting layer 70, and the bipolar mixed spacer layer 60 on the rear side and the blue light ultra-thin light-emitting layer 80 to form a layered and discontinuous li...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, especially in that:

[0039] In this embodiment, a method for preparing a stable white light organic thin film electroluminescent device with a bipolar mixed spacer layer comprises the following steps:

[0040] S1: This step is the same as the first embodiment;

[0041] S2: This step is the same as the first embodiment;

[0042] S3: Transfer the glass substrate sputtered with a layer of ITO conductive film with a thickness of 150nm to a pressure of 10 -4 In the high vacuum cavity under Pa, then on the anode 20 prepared in the step S2, by vacuum evaporation method, sequentially deposit and form a hole injection layer 30, a hole transport layer 40, an orange light ultra-thin light-emitting layer 50, The bipolar mixed spacer layer 60 on the front side, the green light ultra-thin light-emitting layer 70, the bipolar mixed spacer layer 60 on the back side, the blue light ultra-thin light-emitting layer 80, the electron...

Embodiment 3

[0046] This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this embodiment, a method for preparing a stable white light organic thin film electroluminescent device with a bipolar mixed spacer layer comprises the following steps:

[0048] S1: This step is the same as the first embodiment;

[0049] S2: This step is the same as the first embodiment;

[0050] S3: Transfer the glass substrate sputtered with a layer of ITO conductive film with a thickness of 150nm to a pressure of 10 -4 In the high vacuum cavity under Pa, then on the anode 20 prepared in the step S2, by vacuum evaporation method, sequentially deposit and form a hole injection layer 30, a hole transport layer 40, an orange light ultra-thin light-emitting layer 50, The bipolar mixed spacer layer 60 on the front side, the green light ultra-thin light-emitting layer 70, the bipolar mixed spacer layer 60 on the back side, the blue light ultra-thin light-emitting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com