White light electroluminescent device and preparation method and application thereof

An electroluminescence device and electroluminescence technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of poor electroluminescence spectral stability, poor charge transfer and injection performance, and difficulty in meeting high-quality lighting. and other issues, to achieve high external quantum efficiency, reduce material costs, and achieve the effect of external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

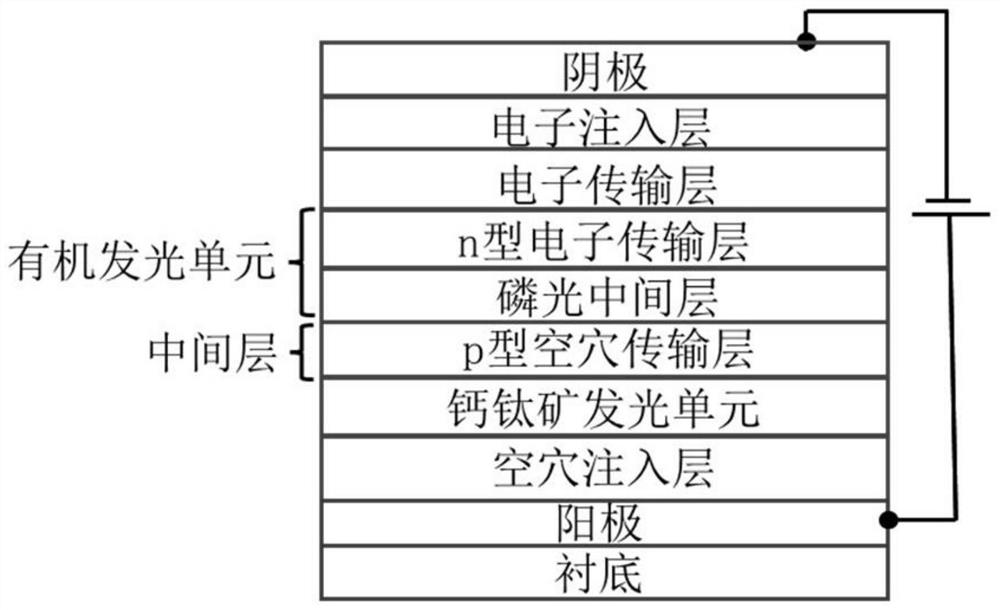

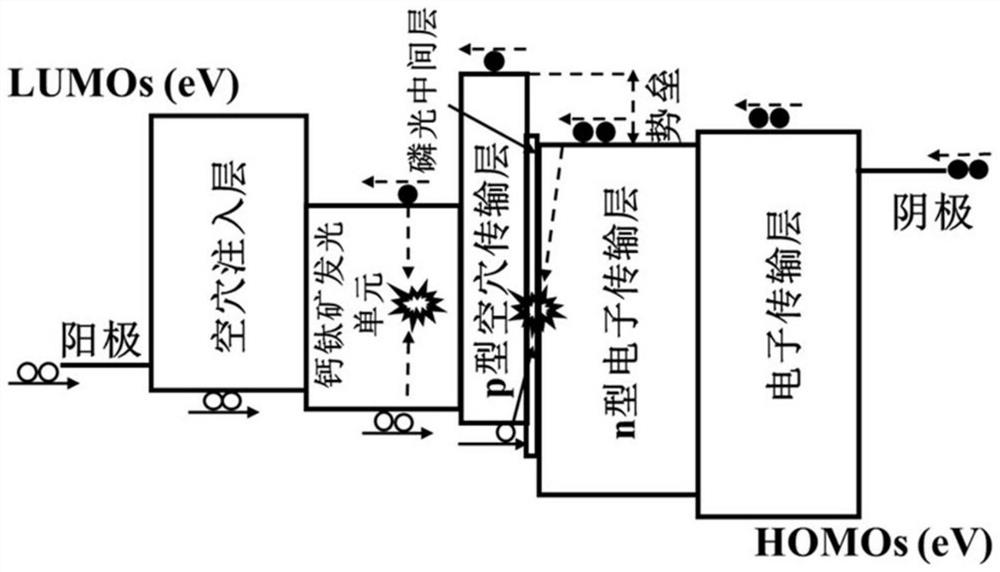

[0045] A kind of white electroluminescent device (structural schematic diagram is as figure 1 As shown, the schematic diagram of the distribution of energy levels and exciton recombination regions is shown in figure 2 shown), which consists of a substrate (ITO glass substrate), a hole injection layer (m-PEDOT:PSS with a thickness of 30nm), a perovskite light-emitting unit, a p-type hole transport layer (intermediate layer; a thickness of 5nm TAPC), phosphorescent interlayer (FIrpic with 1nm thickness), n-type electron transport layer (BOCzPh with 20nm thickness), electron transport layer (TPBi with 30nm thickness), electron injection layer (CsF ) and cathode (Al with a thickness of 120nm), where the ITO glass substrate is both the substrate and the anode, m-PEDOT:PSS is the hole injection layer, TPBi is the electron transport layer, and CsF is the electron injection layer , the perovskite light-emitting unit, the intermediate layer and the organic light-emitting unit (TAPC / F...

Embodiment 2

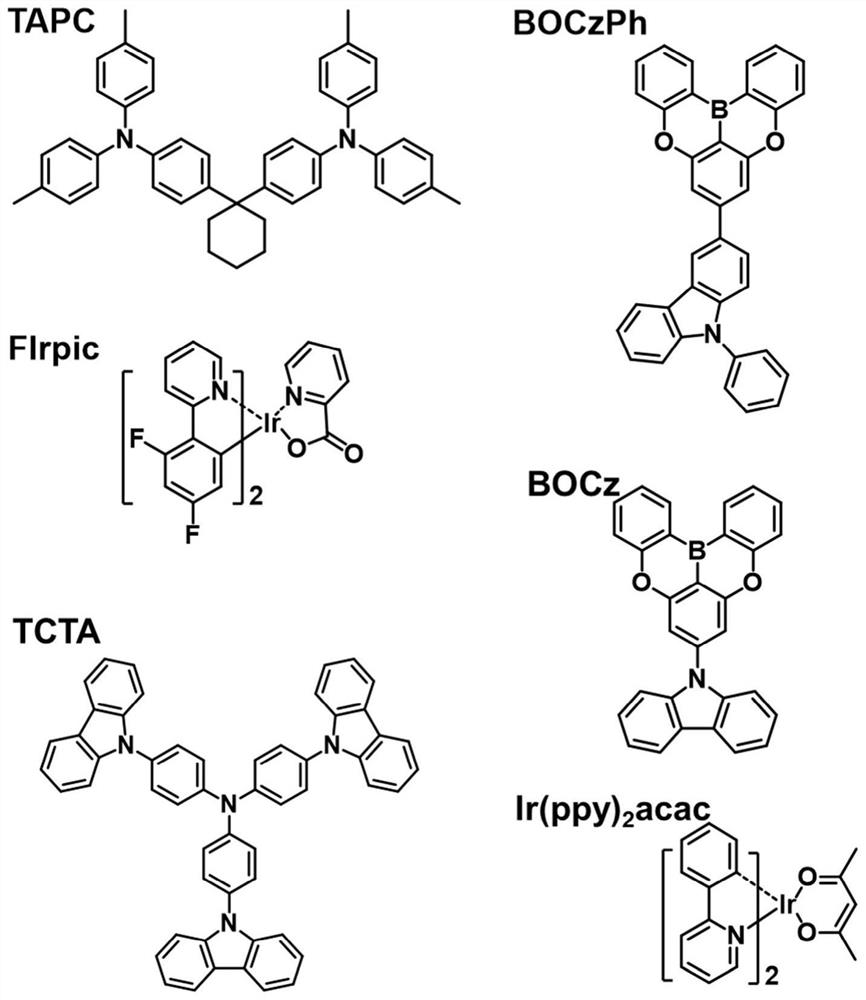

[0060] A kind of white light electroluminescent device, it is by ITO glass substrate, thickness is the m-PEDOT:PSS of 30nm, perovskite light-emitting unit, thickness is the TCTA of 5nm:Ir(ppy) 2 acac (3wt%), TAPC:BOCz (1:1):FIrpic (10wt%) with a thickness of 20nm, TPBi with a thickness of 30nm, CsF with a thickness of 1.2nm and Al with a thickness of 120nm. The ITO glass substrate is both the substrate and the anode, m-PEDOT:PSS is the hole injection layer, TPBi is the electron transport layer, CsF is the electron injection layer, the perovskite light-emitting unit and the intermediate layer (TCTA:Ir(ppy)2acac ) and the organic light-emitting unit (TAPC:BOCz:FIrpic) are the common light-emitting layer (the structural formula of the light-emitting material in the organic light-emitting unit is as follows image 3 shown).

[0061] The preparation method of the above-mentioned white light electroluminescence device comprises the following steps:

[0062] 1) Clean the ITO glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com