Charging generator

A charging machine and warehouse technology, applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems of heavy overall weight of the charging machine, high energy consumption of train operation, and large radiator, so as to reduce the energy consumption of train operation, Improved cooling efficiency and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

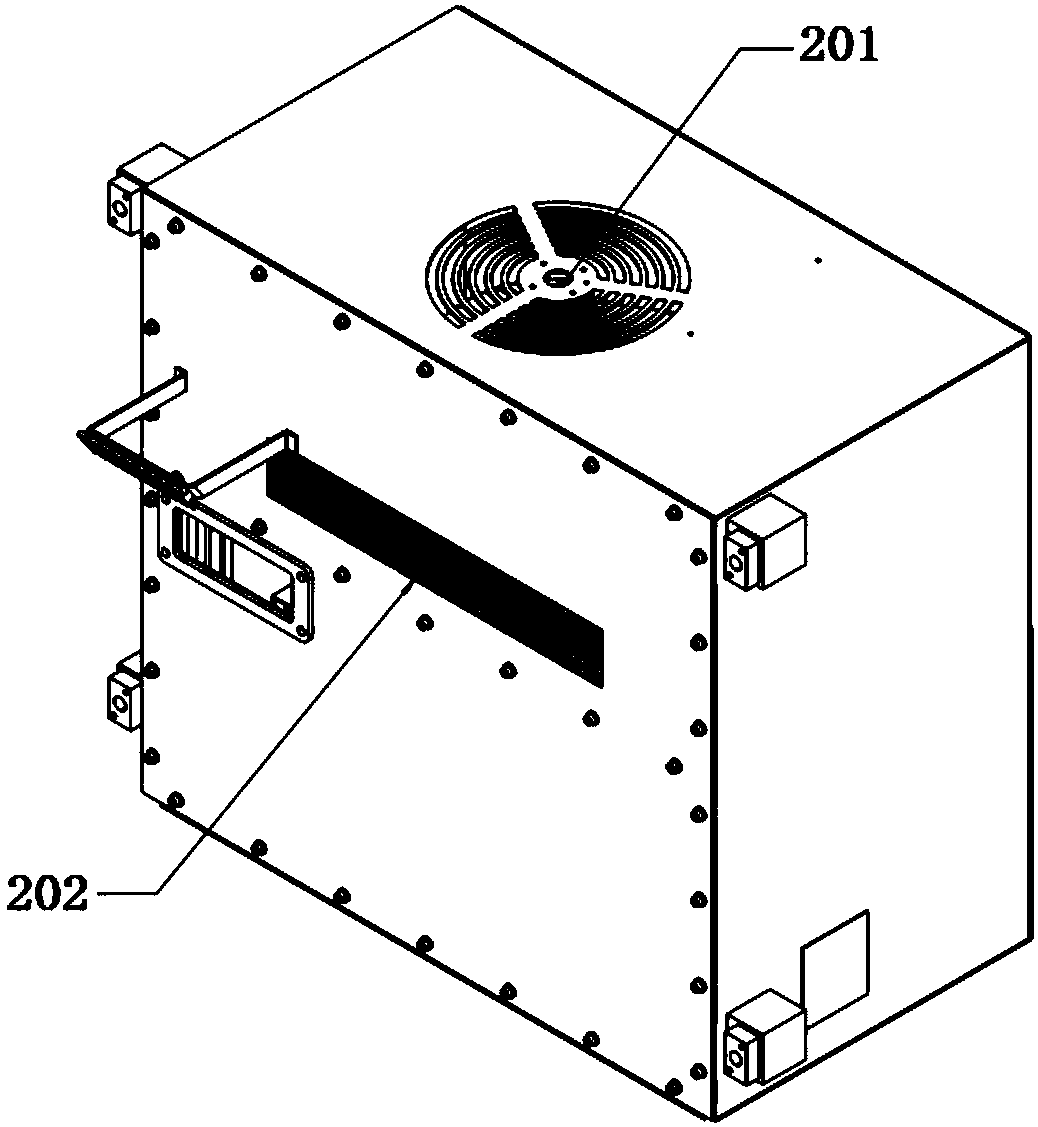

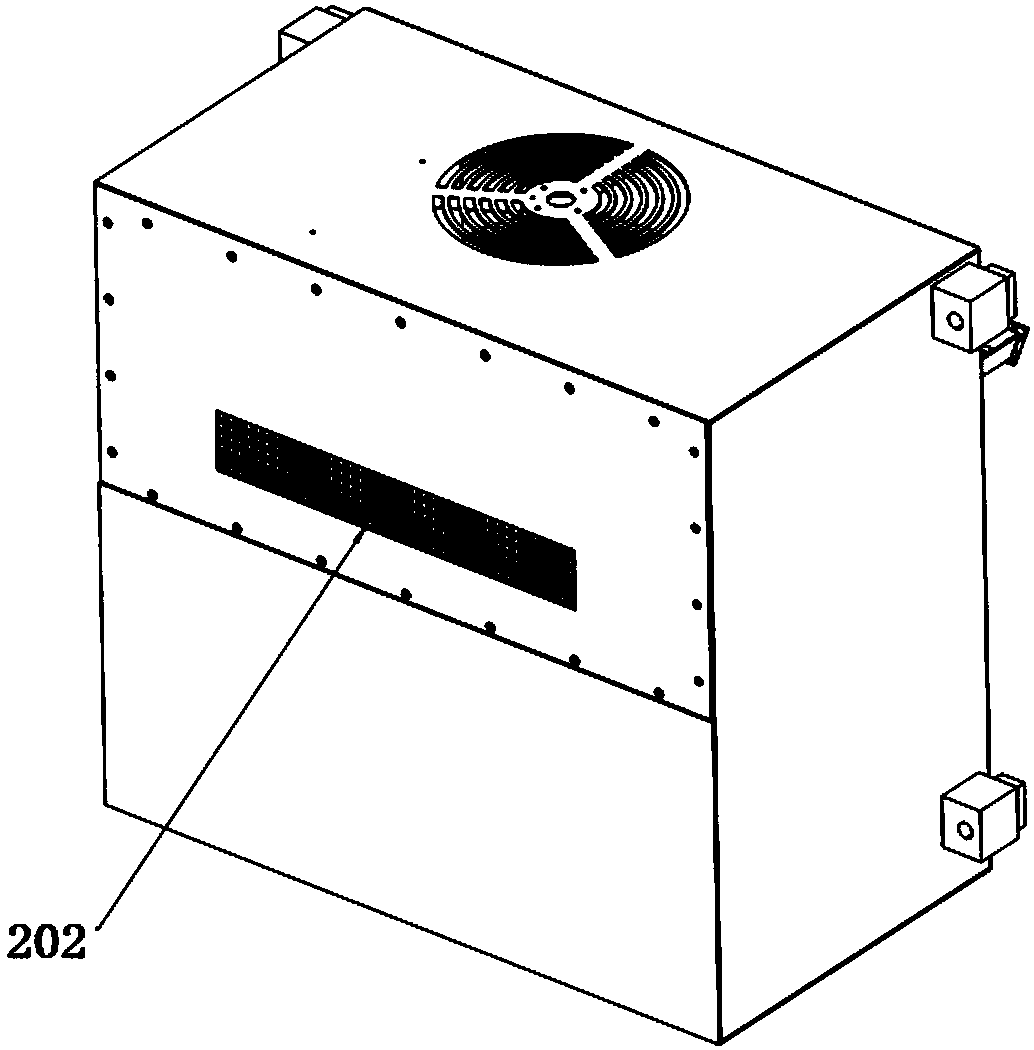

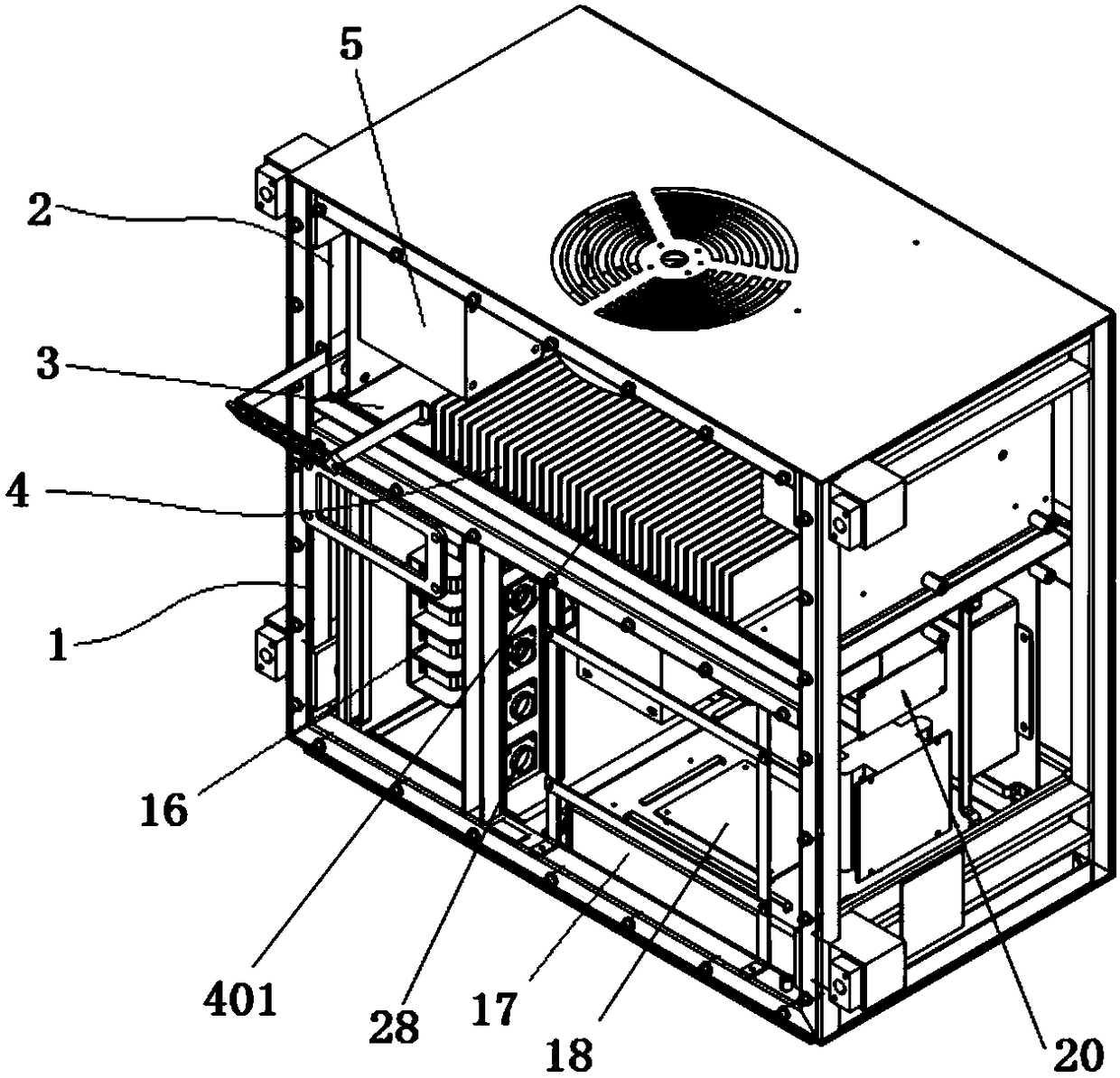

[0020] Such as figure 1 , image 3 and Figure 4 As shown, a charging machine includes a front compartment 1, a rear compartment 2 and a partition plate 3 separating the front compartment and the rear compartment, and also includes a radiator 4, which is installed At the mounting opening reserved on the partition plate, the radiator is mainly composed of a mounting surface 401 and a number of cooling fins 402 extending from the mounting surface. The gap between the radiator and the partition plate Preferably, the gap between the radiator and the partition plate is sealed with a sealant; the installation surface is arranged in the front compartment, and the cooling fins are arranged in the rear compartment. The shell forming the front compartment and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com