Sensing layer formation

A structure and gas technology, applied in the field of selective area heating, can solve the problems of not knowing the advantages of selective area heating, etc., and achieve the effect of improving performance and manufacturing output, high output, and simple output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

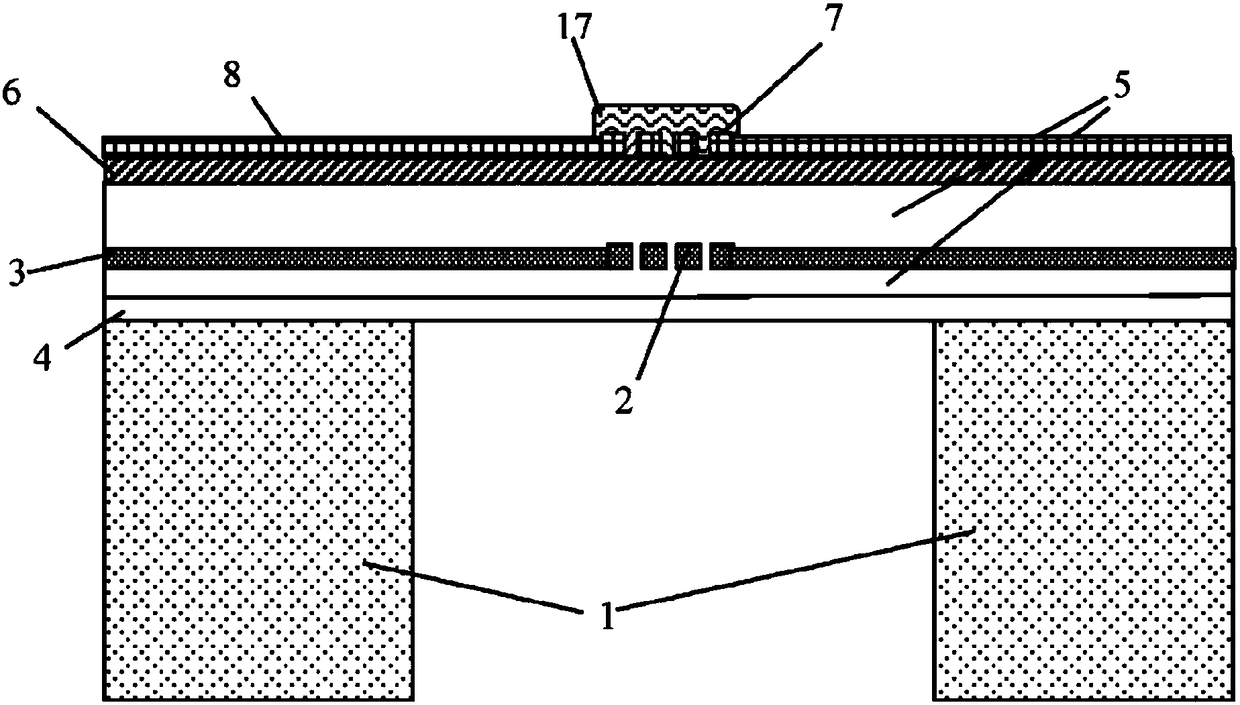

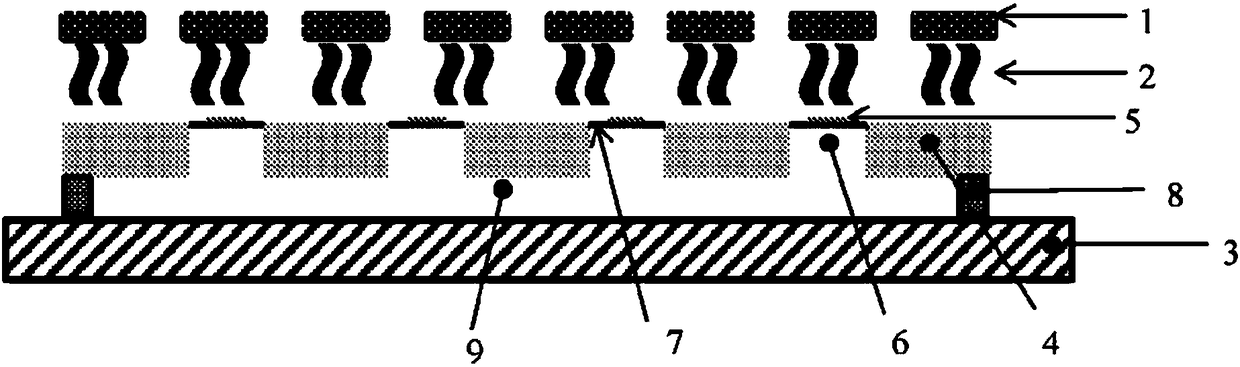

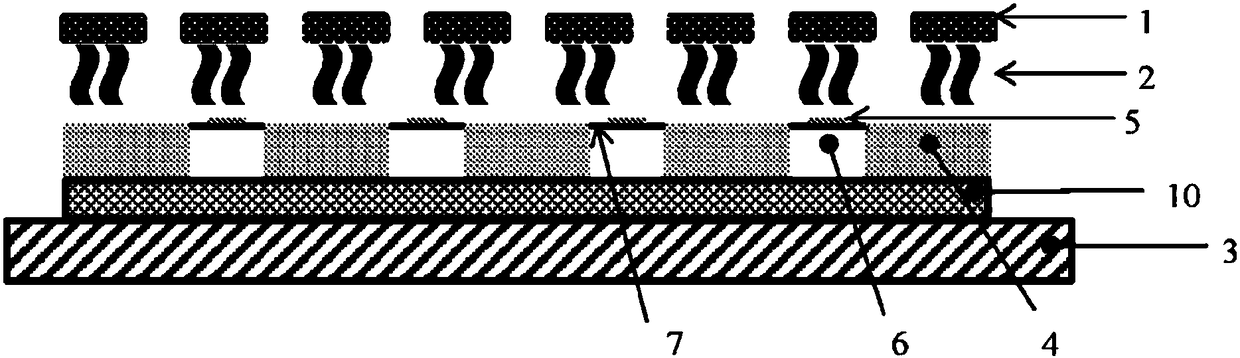

[0074] figure 2 A schematic cross-section of the IR heating process applied on multiple micro-hotplates is shown. All of multiple micro-hotplates can be located on a single chip or wafer. IR heating is applied to the gas sensing material, metal oxide 5, on the electrodes. In this example, the IR heating process involves the use of an array of infrared heaters 1 and a cooled substrate (or cooling structure) 3 . The substrate 4 is heated by infrared radiation 2 from the infrared heater 1 . In this particular embodiment, for example, the substrate 4 is represented by a silicon wafer with etched cavities 6 to form a membrane 7 on which a metal oxide (or sensing structure) 5 is deposited. The substrate 4 is separated from the cooled chuck or cooling plate by a support structure 8 to form a thermal isolation zone 9 . The gap 9 can be filled with air or a combination of one or more gases. The pressure can be adjusted to change the thermal coupling between the wafer and cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com