Zero emission treatment system and process for landfill leachate concentrated liquor

A technology of landfill leachate and treatment system, applied in the field of landfill leachate treatment system, can solve the problem of high cost and achieve the effects of efficient removal, feasible technology and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

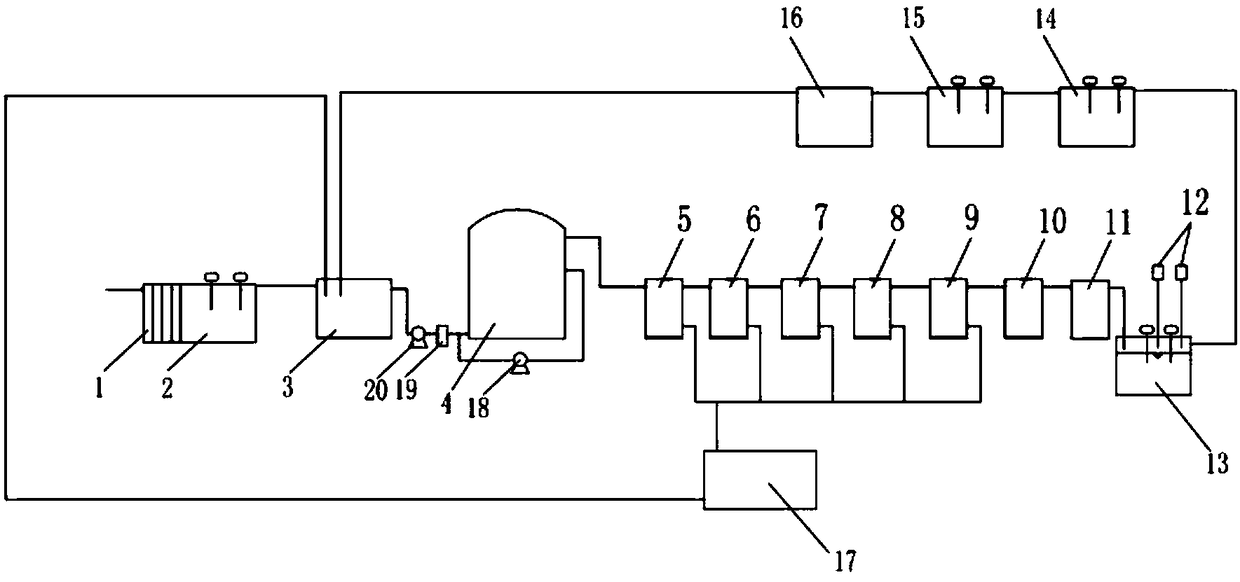

[0041] figure 1 The landfill leachate concentrate zero-emission treatment system shown is an embodiment of the present invention, including a pretreatment system, a conditioning tank 3, an MS anaerobic system, an MBR system, a nanofiltration membrane system, a sludge treatment system, and a system for treating Advanced Oxidative Desalination Conjugate System for Landfill Leachate Concentrate. The pretreatment system, the conditioning tank 3, the MS anaerobic system, the MBR system and the nanofiltration membrane system are connected in sequence to form a landfill leachate treatment subsystem for the treatment of landfill leachate. The conjugate system is connected, and the landfill leachate concentrate produced by the nanofiltration membrane system is sent to the advanced oxidation desalination conjugate system for oxidative desalination treatment.

[0042] The pretreatment system includes a grid tank 1 and a coagulation sedimentation tank 2 which are connected in sequence, a...

Embodiment 2

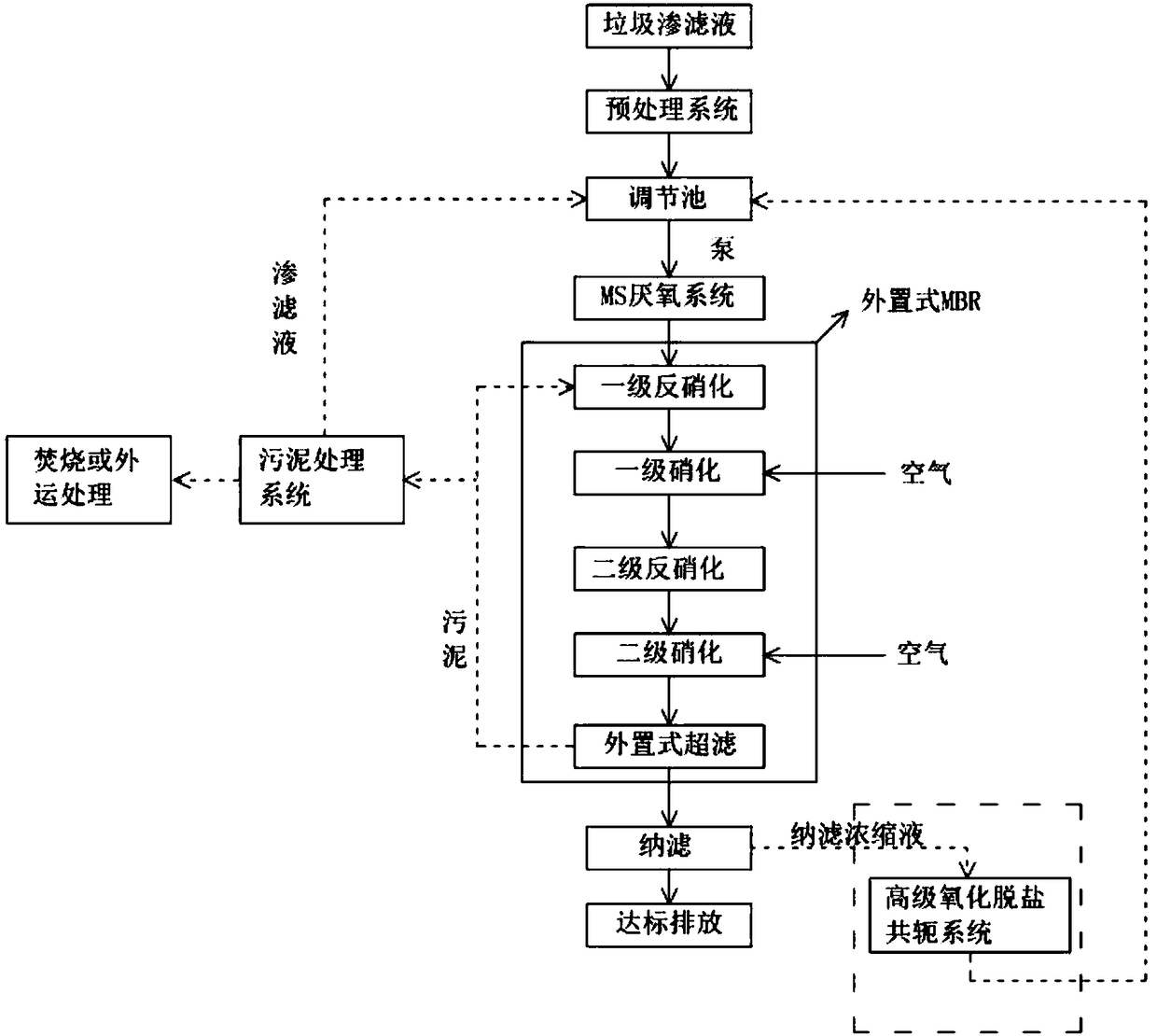

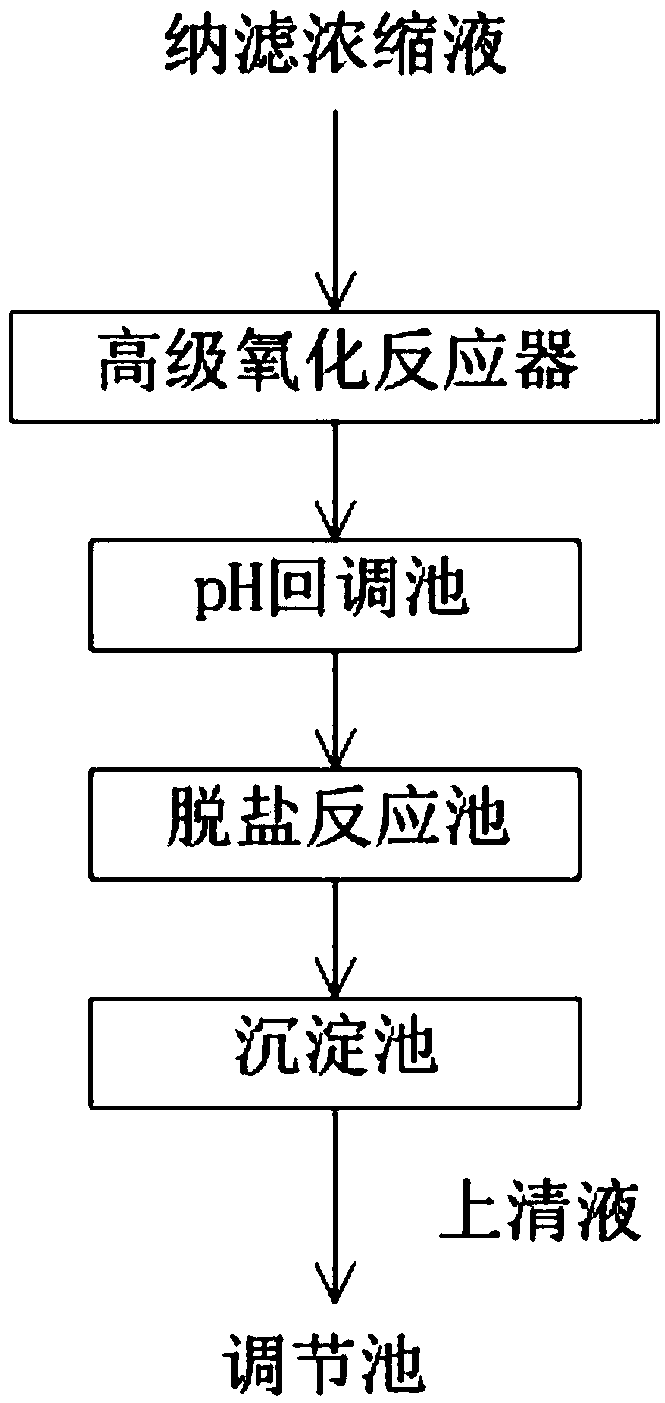

[0050] figure 2 and image 3 Shown is the process flow of this embodiment.

[0051] (1) Landfill leachate enters the pretreatment system through the pipeline for pretreatment. Influent water quality: COD≤50000mg / L, BOD 5 ≤30000mg / L, NH 3 -N≤1800mg / L, SO 4 2-≤1000mg / L. The landfill leachate first enters the grid tank 1, and the hydraulic screen in the tank can remove the larger particles floating in the leachate, reduce the sedimentation of the suspended matter in the regulating tank 3 and block the subsequent pipes and pumps. The effluent from the grid tank 1 enters the coagulation and sedimentation tank 2, and after coagulation and sedimentation treatment, most of the pollutants such as suspended solids, sulfur ions, and heavy metal ions in the wastewater are removed, and then flows into the adjustment tank 3 by itself. The residence time of the adjustment tank 3 is more than 7d, and under the stirring action of the submerged stirring device, the leachate in different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com