Water leakage repairing process for air face

A backwater and water leakage technology, applied in building maintenance, building components, adhesive additives, etc., can solve problems such as waterproof failure, water leakage, waterproof damage, etc., and achieve the effect of solving the problem of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

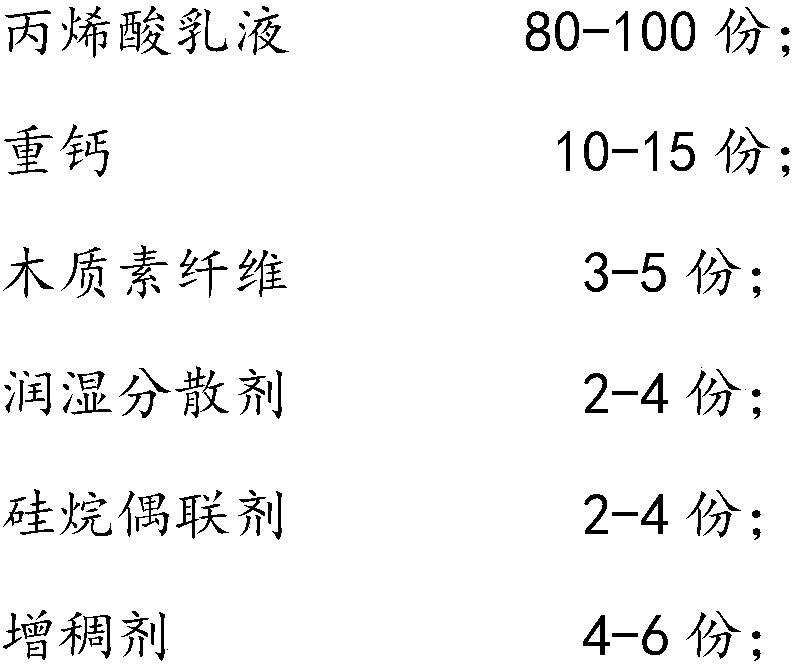

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the use and purpose of these exemplary embodiments are only used to exemplify the present invention, and do not constitute any form of any limitation on the actual protection scope of the present invention, let alone The protection scope of the present invention is limited thereto.

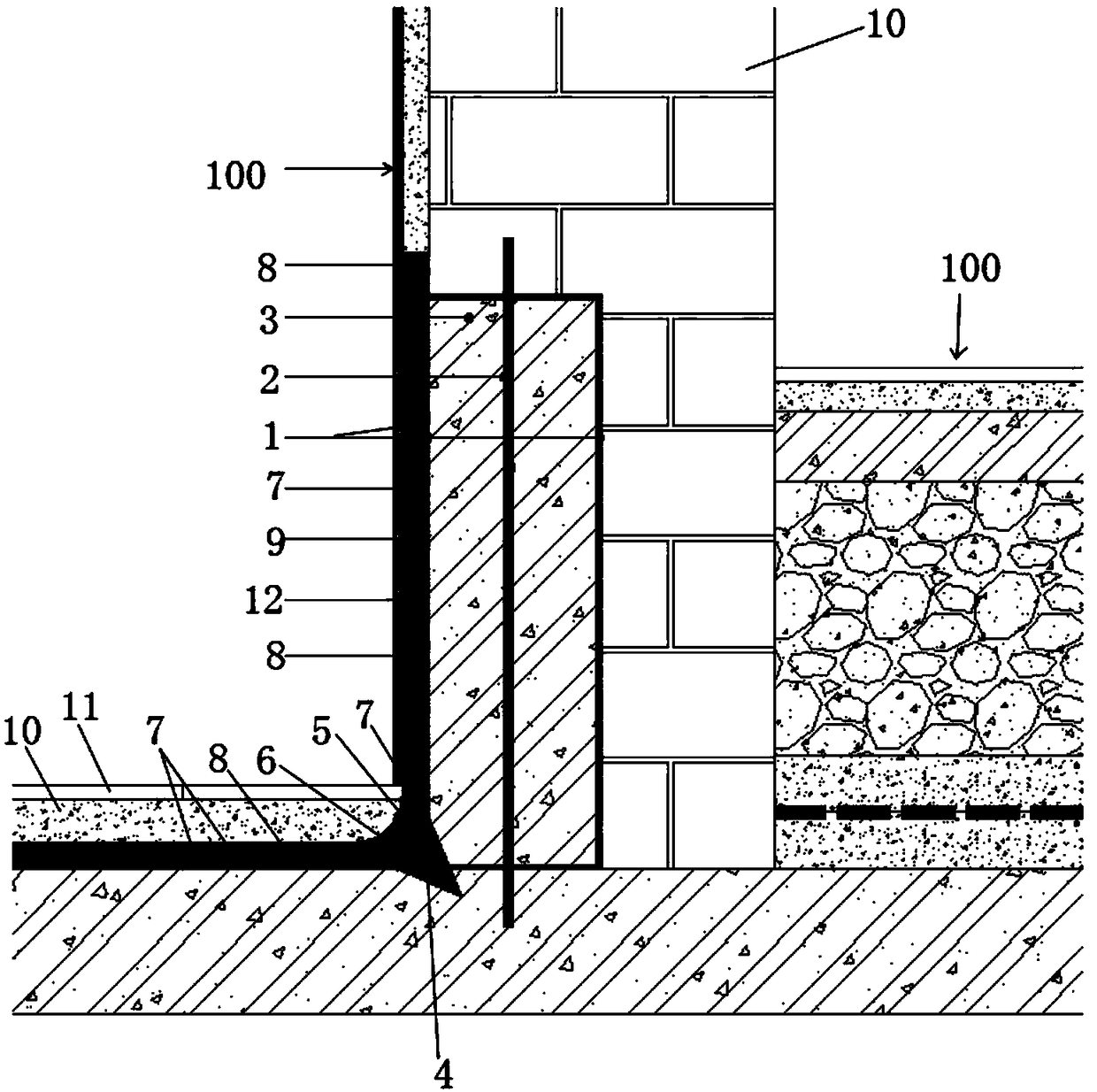

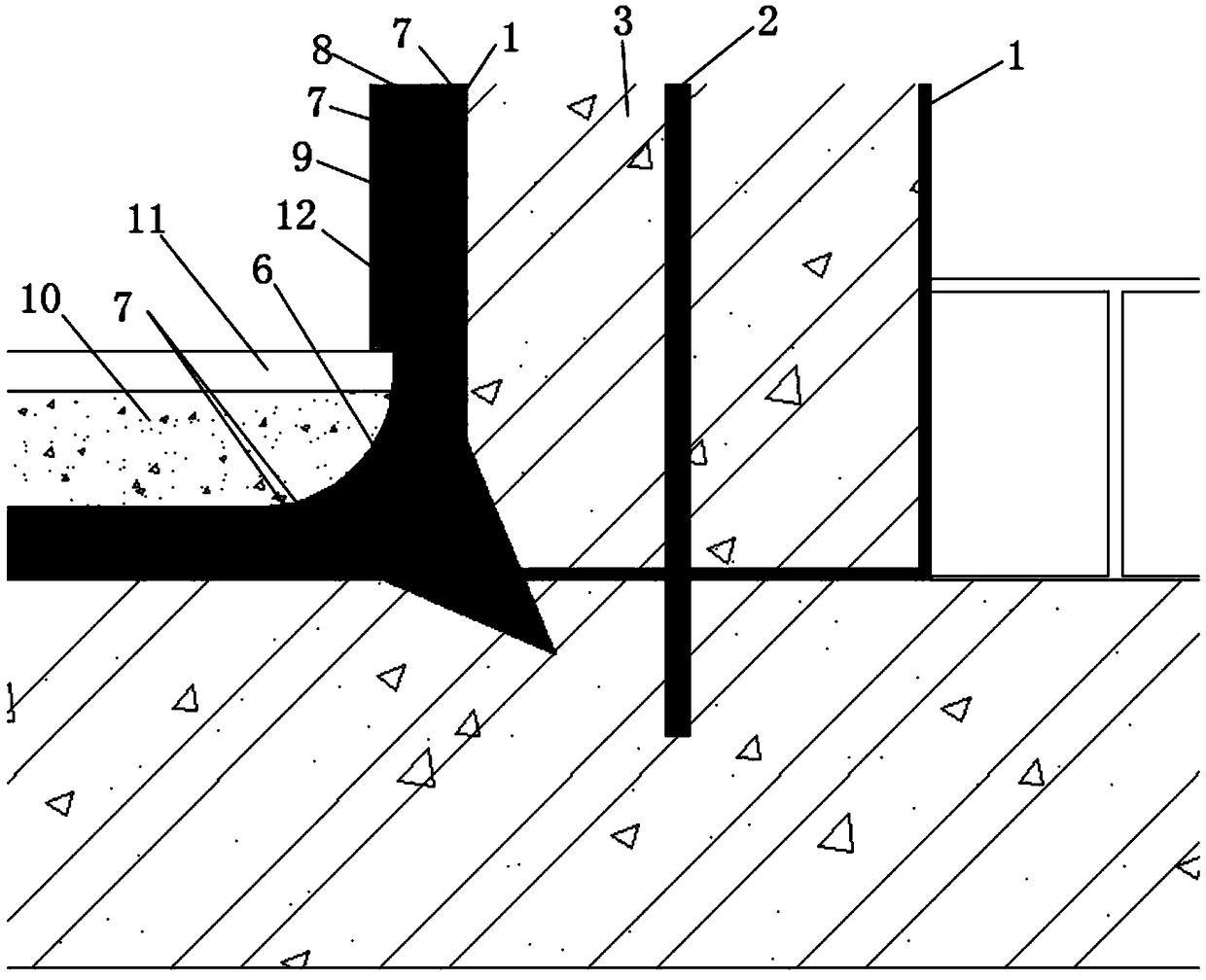

[0048] see figure 1 and figure 2 As shown, a water leakage repair process on the back surface includes the following steps:

[0049] S1. Cut the brick wall 10 built by the wall body on the back surface, and the cutting height is more than 80mm higher than the decorative surface layer on the water facing surface, which is 80mm in this embodiment; 1 / 2-2 / 3 of the thickness of the wall body is cut off, and this embodiment is 2 / 3; form the construction part; in order to better understand the location of the construction part, figure 1 The original structural lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com