Jacket corrosion detection equipment and method free of magnetic field interference

A corrosion detection and jacket technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through electromagnetic means, can solve the problems of difficult jacket corrosion detection and low inspection efficiency, and achieve avoidance of electromagnetic interference, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

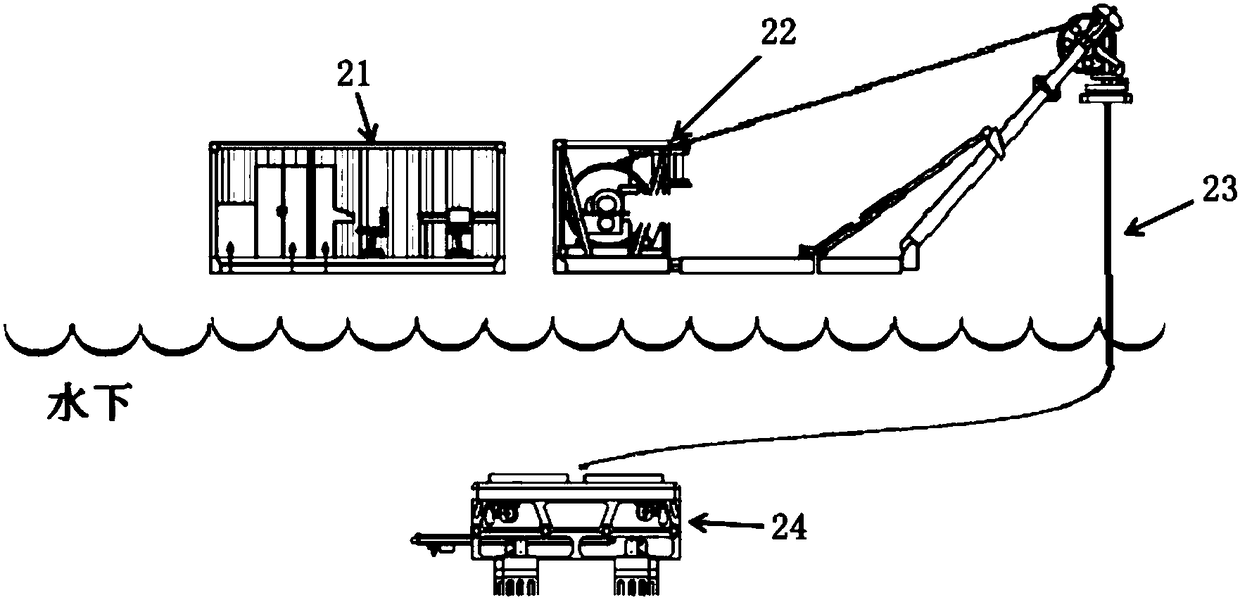

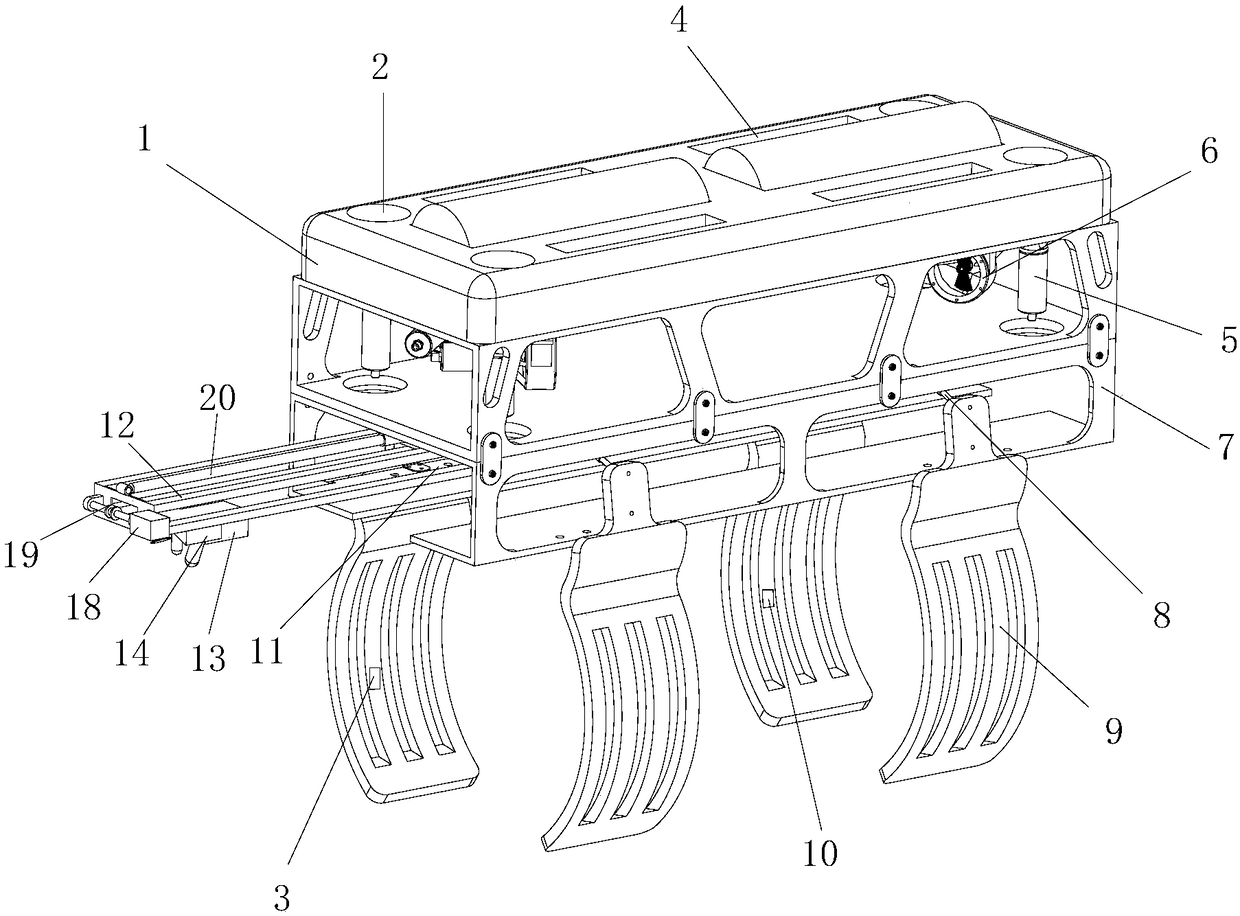

[0040] Such as Figure 1 to Figure 8 As shown, a jacket corrosion detection equipment without magnetic field interference includes a control and data real-time interaction system 21 , a release recovery system 22 , an umbilical cable 23 and a jacket corrosion detection crawling robot 24 .

[0041] The control and data real-time interaction system 21 includes a shore station display and operation unit and a shore-based power supply unit, which are responsible for real-time control of the jacket corrosion detection crawling robot 24, analysis and storage of the measurement data detected by the corrosion detection unit, and for all The crawler robot for jacket corrosion detection described above provides power.

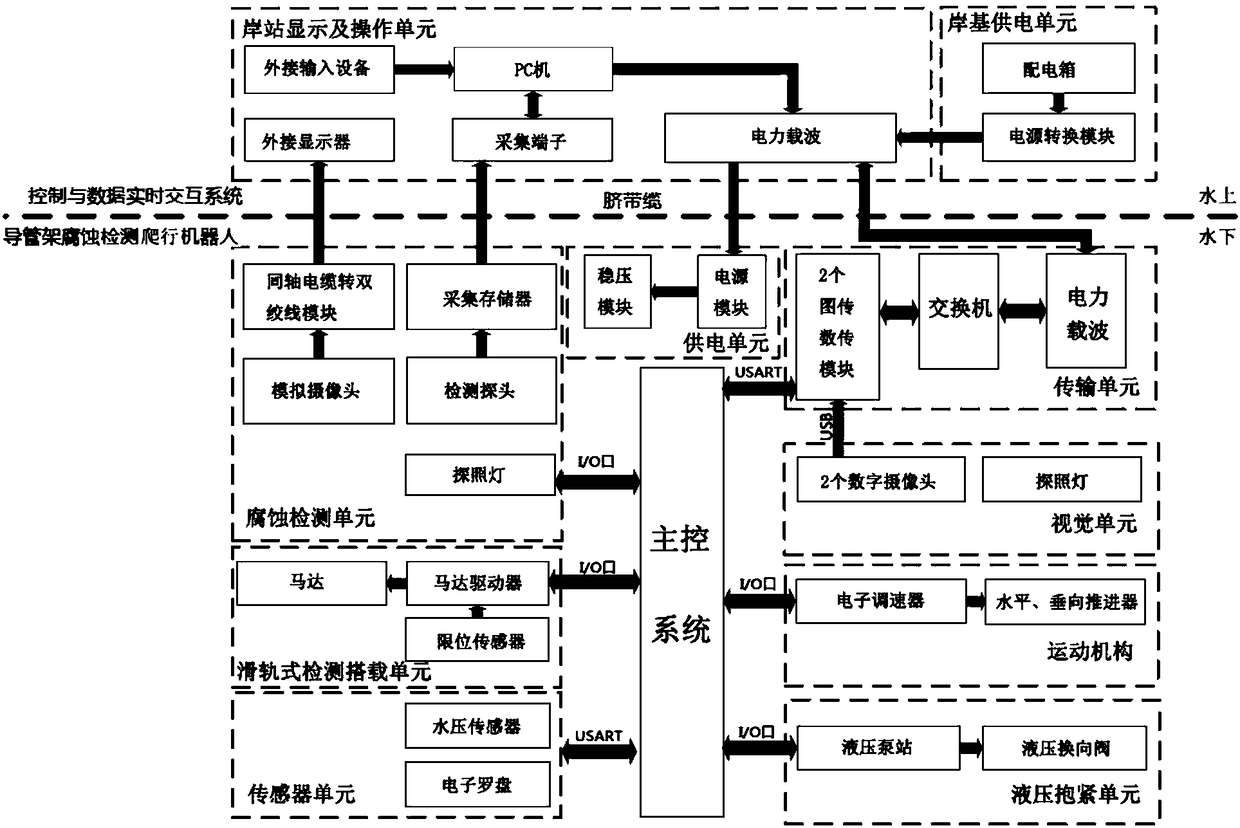

[0042] Specifically, as figure 2 As shown, the display and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com