Surface modification method of lithium secondary battery negative electrode, ag modified lithium electrode prepared by using the method and application

A lithium secondary battery, surface modification technology, applied in the field of electrochemical batteries, can solve the problems of negative electrode specific capacity and energy density reduction, increase manufacturing cost, difficult operation, etc., achieve cycle performance and safety performance improvement, and inhibit lithium branch Crystal, reducing the effect of non-Faradaic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using nano-Ag powder with a particle size of 2 O2 Prepare a nano-Ag THF solution with a concentration of 1.0 mg / ml in an argon glove box of <0.1 ppm, heat and ultrasonically treat it for 24 hours, and take the upper suspension; then take the pretreated lithium foil with a bright surface, and punch it into a 16 mm diameter A number of discs, take the above suspension and drop it on the surface of the disc, let it stand for 1min, and get the pole piece after the tetrahydrofuran volatilizes. permanent lithium electrodes.

Embodiment 2

[0022] Using nano-Ag powder with a particle size of 2 O2 Prepare a nano-Ag THF solution with a concentration of 0.8mg / ml in an argon glove box with <0.1ppm, heat and ultrasonically treat it for 12 hours, and take the upper suspension; then take the pretreated lithium foil with a bright surface and punch it into a 16mm diameter A number of discs, take the above suspension and drop it on the surface of the disc, let it stand for 1min, and get the pole piece after the tetrahydrofuran volatilizes. permanent lithium electrodes.

Embodiment 3

[0024] Using nano-Ag powder with a particle size of 2 O2 Prepare a nano-Ag THF solution with a concentration of 1.0 mg / ml in an argon glove box of <0.1 ppm, heat and ultrasonically treat it for 24 hours, and take the upper suspension; then take the pretreated lithium foil with a bright surface, and punch it into a 16 mm diameter A number of discs, take the above suspension and drop it on the surface of the disc, let it stand for 1min, and get the pole piece after the tetrahydrofuran volatilizes. permanent lithium electrodes.

[0025] The above-mentioned Examples 1 to 3 have all obtained surface-modified lithium electrode sheets, and their surface layers can generate uniform Li-Ag alloys during the electrochemical process, which greatly reduces the non-Faradaic gap between the lithium negative electrode and the electrolyte. reaction, effectively inhibiting the growth of lithium dendrites.

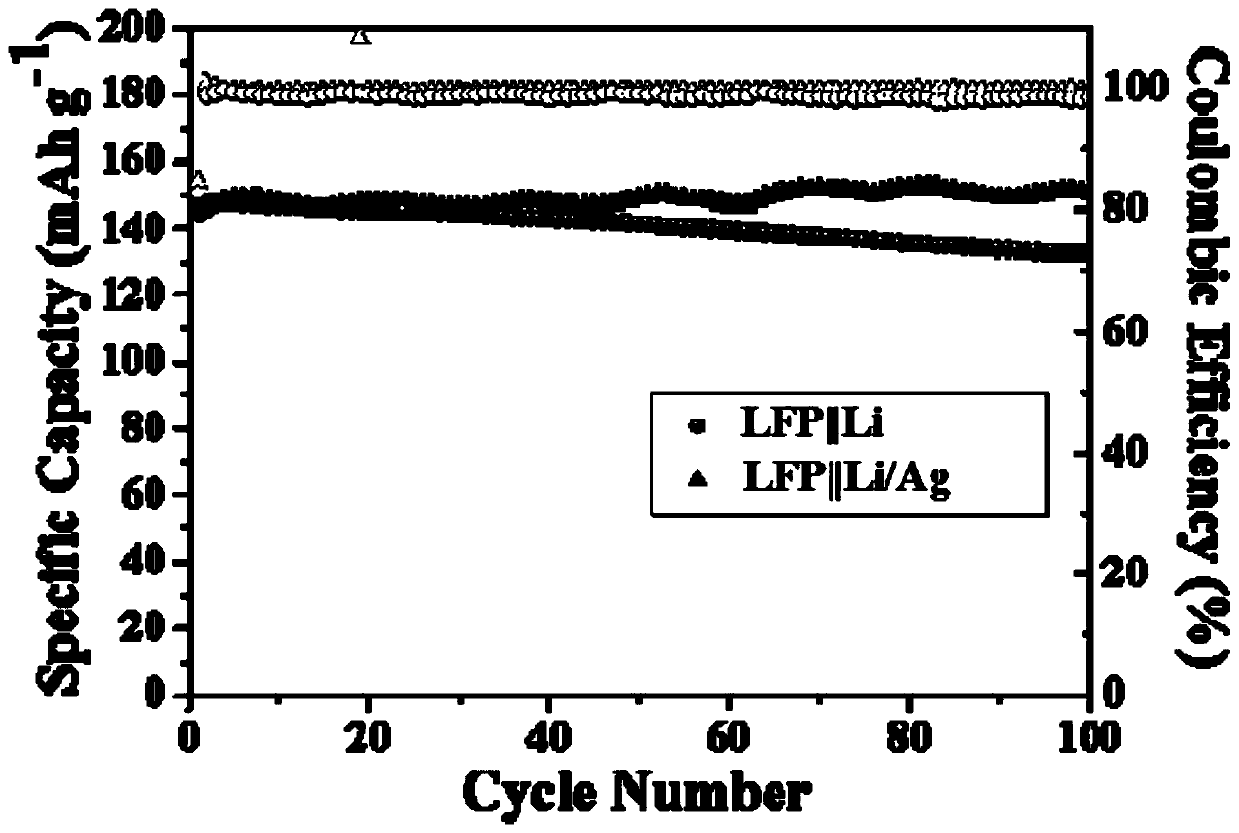

[0026] Next, we take the lithium electrode sheet provided in Example 1 as an example to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com