Lithium ion cell blended positive pole material and its preparing method

A lithium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor stability, technical difficulty, low stability and safety performance, and achieve high working voltage, good safety performance, and automatic The effect of small discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

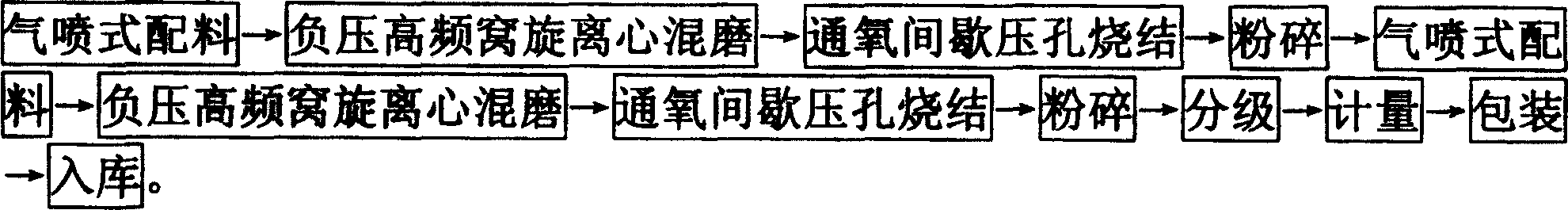

Method used

Image

Examples

Embodiment 1

[0025] Carry out specific implementation according to the composition material general formula of cobalt manganese niobium M nickel base doped positive electrode material of lithium ion battery: preparation Li 1.06 Ni 0.7 co 0.2 mn 0.04 Nb 0.05 m 0.01 o 2 , first weigh Li according to the molar ratio of Li, Ni, and Co as 1.01:0.7:0.2 2 CO 3 、Co 3 o 4 、Ni 2 o 3 1608.52g, 692.95g, and 2285.73g respectively, mixed for 1 hour with an air-jet batching device, and then sent into a negative pressure high-frequency vortex centrifugal mixing tank with a set internal pressure of 0.8 standard atmospheric pressure for 10 hours. The mixed and ground material is put into a sagger of 400mm×320mm×220mm, and then the material in the sagger is compacted and punctured. The thickness of the material after compaction and puncture is 100mm, and then sent to the atmosphere furnace for intermittent oxygen sintering , the heating rate is 500°C / h, rise to 760°C and enter the first constant t...

Embodiment 2

[0027] Preparation of Li 1.06 Ni 0.8 co 0.12 mn 0.02 Nb 0.05 m 0.01 o 2 : First, according to the molar ratio of Li, Ni and Co as 1.08:0.8:0.12, weigh Li 2 CO 3 、Co 3 o 4 、Ni 2 o 3 , mixed for 1 hour with an air-spray batching equipment, then sent into a negative pressure high-frequency vortex centrifugal mixing tank with a set internal pressure of 0.8 standard atmospheric pressure for 10 hours of mixing and grinding, and the mixed grinding material was packed into a 400mm (long ) × 320mm (width) × 220mm (height) sagger, the material in the sagger is compacted and punched, the compacted thickness is 100mm, and then sent into the atmosphere furnace, the speed of intermittent oxygen sintering is 400 ℃ / h , rise to 700°C and enter the first constant temperature zone, the constant temperature time is 5h, and then enter the second constant temperature zone, the temperature in the second constant temperature zone is controlled at 800°C, the constant temperature time is 6...

Embodiment 3

[0029] Preparation of Li 1.06 Ni 0.5 co 0.2 mn 0.19 Nb M.1 m 0.01 o 2 : First, weigh Li according to the molar ratio of Li, Ni and Co as 1.01:0.5:0.2. 2 CO 3 、Co 3 o 4 、Ni 2 o 3 , mixed for 1 hour with an air-spray batching equipment, then sent into a negative pressure high-frequency vortex centrifugal mixing tank with a set internal pressure of 0.8 standard atmospheric pressure for 10 hours of mixing and grinding, and the mixed grinding materials were put into a sagger, The material in the sagger is then compacted and punched. The thickness of the material after compacting and punching is 100mm, and then sent to the atmosphere furnace for intermittent oxygen sintering. The heating rate is 300°C / h, rising to 750°C and entering the first Constant temperature zone, the constant temperature time is 6h, and then enter the second constant temperature zone, the temperature in the second constant temperature zone is controlled at 890°C, the constant temperature time is 8h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com