A kind of positive electrode slurry and preparation method thereof

A technology of positive electrode slurry and positive active material, which is applied in battery electrodes, secondary battery repair/maintenance, structural parts, etc., can solve problems such as difficult to meet the safety requirements of high specific energy power batteries, and achieve reduction of standing time, The effect of little influence on electrochemical performance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

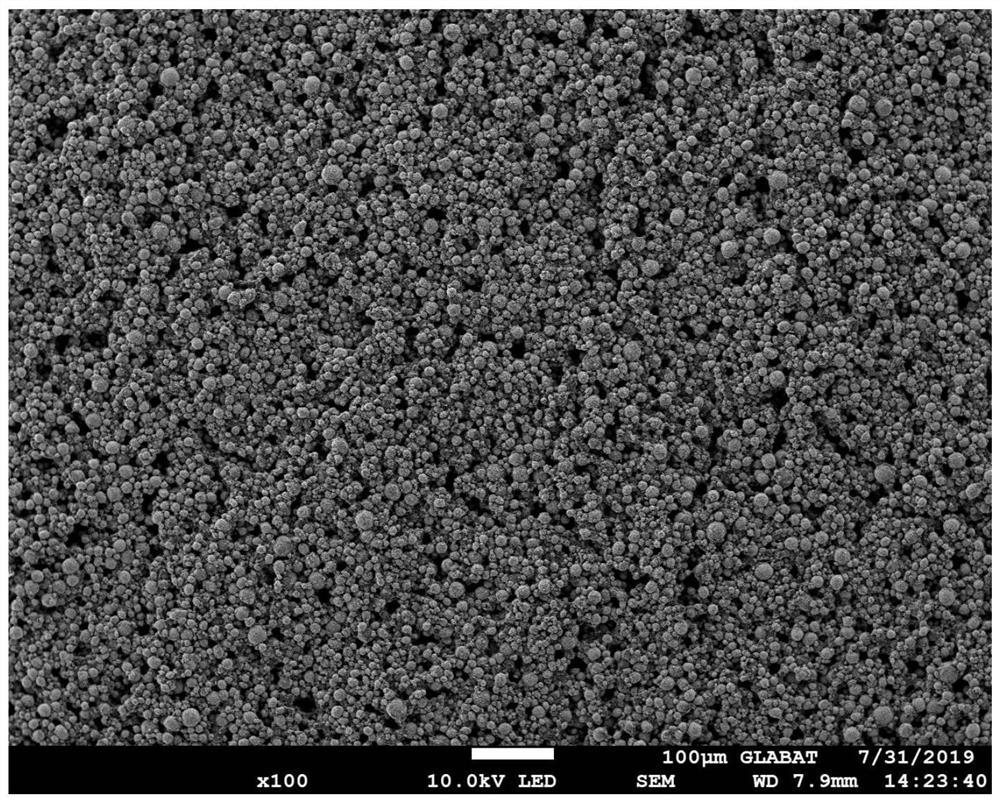

Image

Examples

Embodiment 1

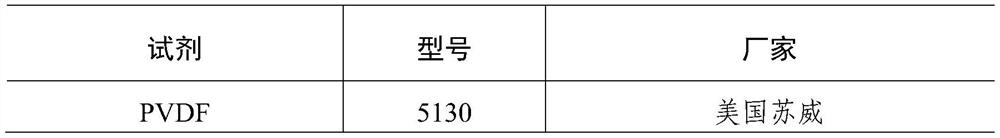

[0037] (1) Dissolve 1.5g PVDF in 28.5g NMP to obtain PVDF glue;

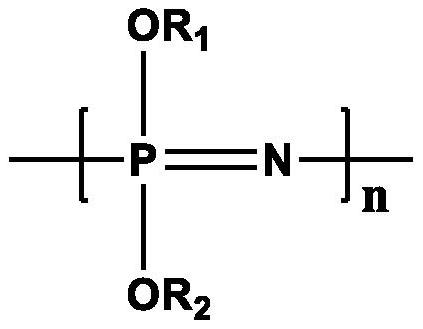

[0038] (2) Mix the above PVDF glue with 0.5g of polyphosphazene A with a number average molecular weight of 10000, add 1.0g of carbon nanotubes, stir at 50°C and 3000r / min for 8h, and obtain a conductive and flame-resistant glue;

[0039] (3) Add 97g NCM523 to the above-mentioned conductive flame-resistant rubber solution, stir at a high speed to disperse evenly, add an appropriate amount of NMP, and prepare positive electrode slurry with a solid content of 60%;

[0040] (4) Scrape-coat the above positive electrode slurry on both sides of the aluminum foil current collector, and dry at 80°C for 4 hours to obtain a positive electrode sheet with an areal density of 15 g / cm 2 .

[0041] A 2032 button battery was assembled by using the positive pole piece prepared in Example 1. After testing, the 0.1C discharge specific capacity of the positive material was 167.9 mAh / g, and the initial efficiency was 88.8%.

[004...

Embodiment 2

[0047] (1) Dissolve 2.5g PVDF in 22.5g NMP to obtain PVDF glue;

[0048] (2) Mix the above-mentioned PVDF glue with 1.5g of polyphosphazene B with a number average molecular weight of 1,000,000, add 5.0g of conductive carbon black, stir at 50°C and 3000r / min for 10h, and obtain a conductive flame-resistant glue;

[0049] (3) Add 91g of NCM622 to the above-mentioned conductive flame-resistant rubber solution, stir at high speed to disperse evenly, add an appropriate amount of NMP, and prepare positive electrode slurry with a solid content of 60%;

[0050] (4) Scrape-coat the positive electrode slurry on both sides of the current collector, and dry it at 80°C for 4 hours to obtain a positive electrode sheet, the surface density of which is 35g / cm 2 .

[0051] A 2032 button battery was assembled by using the positive electrode sheet prepared in Example 2. After testing, the 0.1C discharge specific capacity of the positive electrode material was 178.9 mAh / g, and the initial effic...

Embodiment 3

[0056] (1) 3gPVDF was dissolved in 47gNMP to obtain PVDF glue;

[0057] (2) Mix the above PVDF glue with 2.0g of polyphosphazene C with a number average molecular weight of 80,000, add 5.0g of conductive carbon black and carbon nanotubes with a mass ratio of 1:1, and stir for 8h at 50°C and 3000r / min , to obtain conductive flame-resistant glue;

[0058] (3) Add 90g of NCM (the molar ratio of nickel, cobalt, and manganese is 7:1.5:1.5) to the above-mentioned conductive flame-resistant rubber solution, stir at high speed to disperse evenly, add an appropriate amount of NMP, and prepare positive electrode slurry with a solid content of 60%;

[0059] (4) Scrape-coat the above positive electrode slurry on both sides of the current collector, dry at 80°C for 4 hours to obtain a positive electrode sheet, the surface density of the positive electrode sheet is 15g / cm 2 .

[0060] A 2032 button battery was assembled by using the positive pole piece prepared in Example 3. After testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com