Automatic control ultralow-temperature refrigerator heat radiation device

An automatic control and heat dissipation device technology, which is applied in the field of biological and medical experimental auxiliary equipment, can solve the problems of increasing energy consumption pressure of ultra-low temperature freezer air conditioners, reducing the cooling effect of ultra-low temperature freezers, and rising ambient temperature, etc., to achieve flexible installation and pipeline arrangement, The effect of saving input costs, saving installation and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

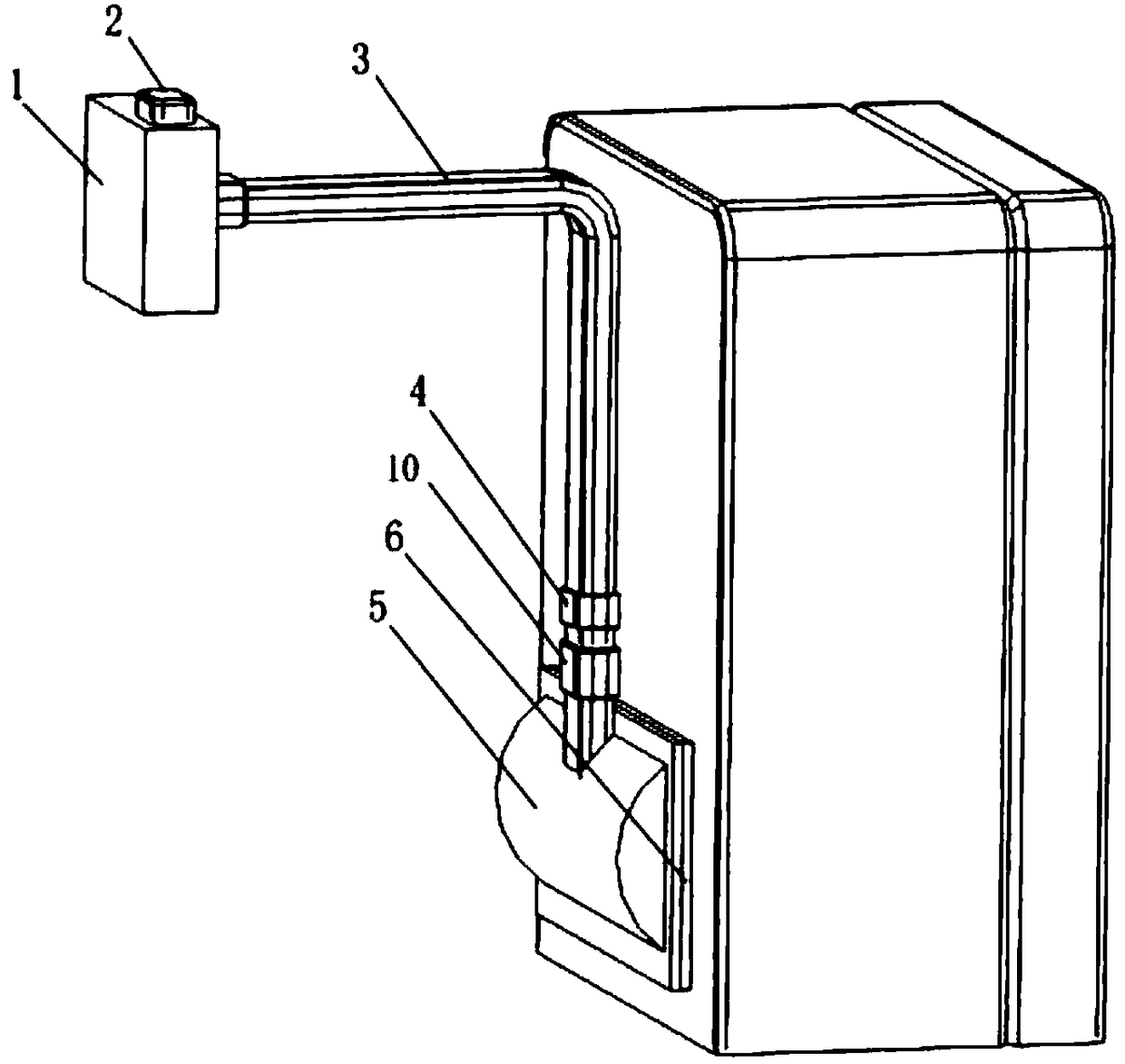

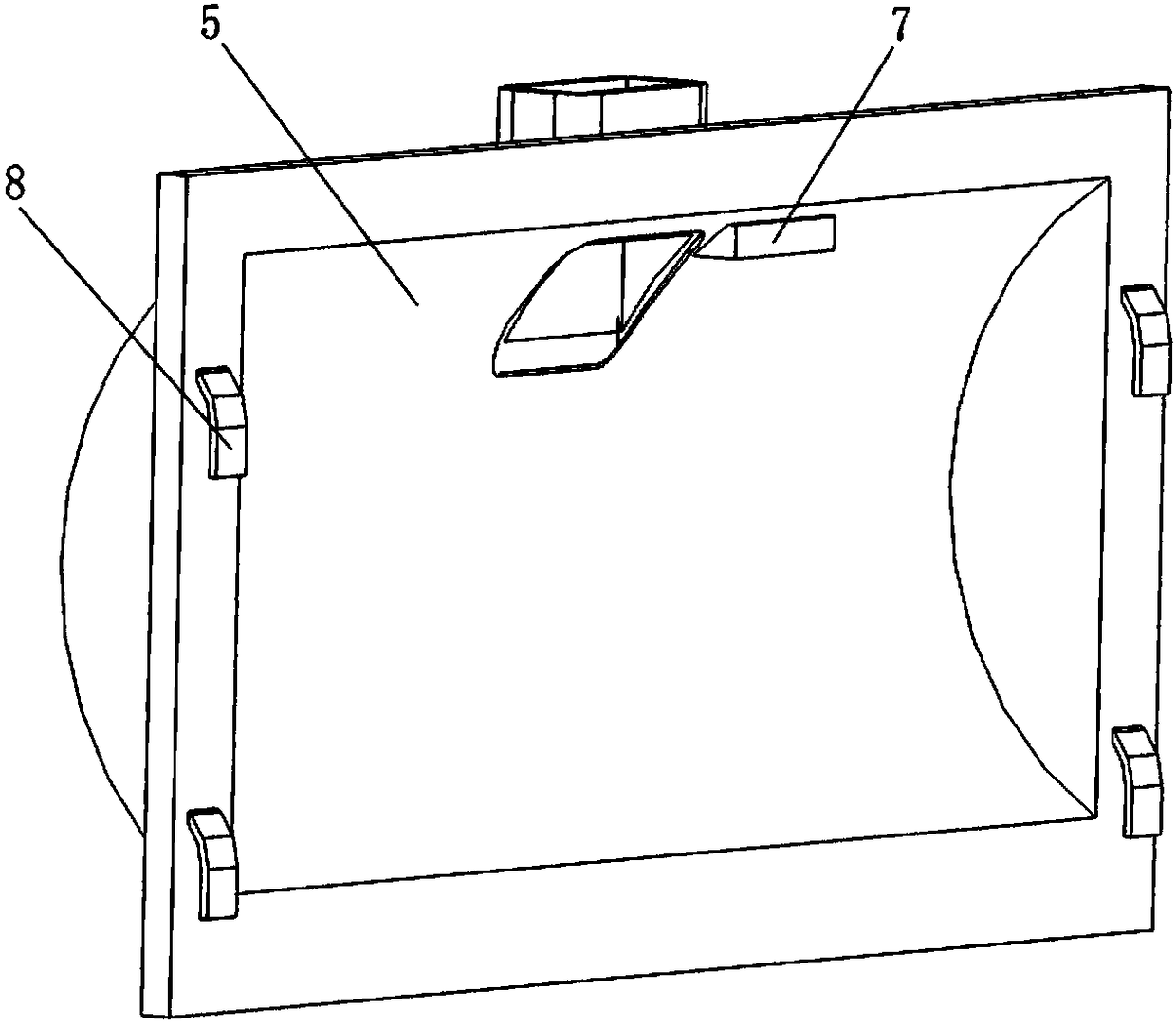

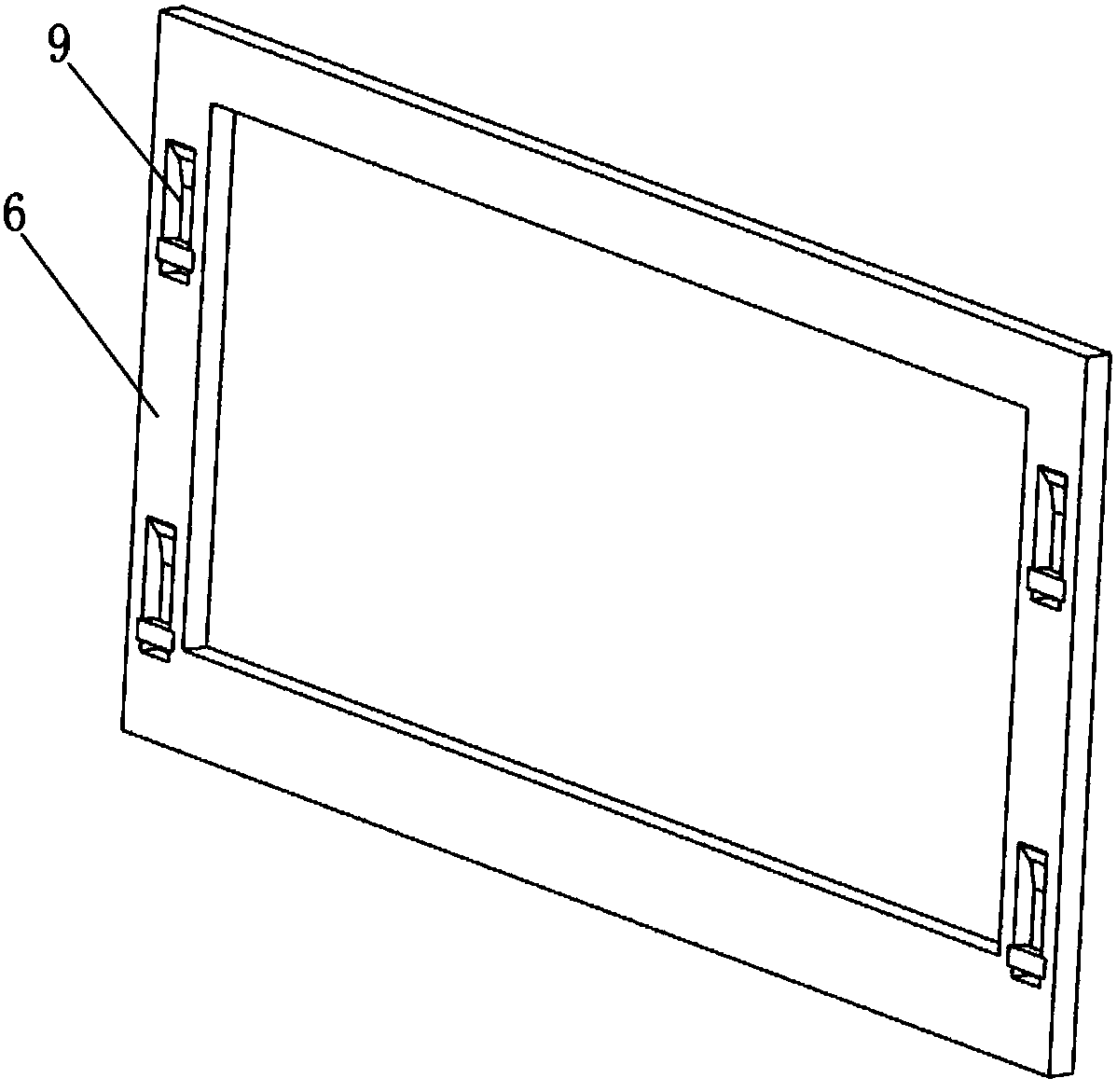

[0024] Such as figure 1 As shown, an automatic control ultra-low temperature refrigerator heat dissipation device includes an exhaust fan 1, a controller 2, an exhaust pipe 3, a pipe connector 4, an exhaust hood 5, an exhaust hood installation frame 6 and a sensor 7, the described One end of the exhaust pipe 3 is connected with an exhaust fan 1 through a pipe connector 4, and the other end of the exhaust pipe 3 is connected with an exhaust cover 5 through a pipe connector 4, so that the arrangement of the exhaust pipe 3 can be flexibly and conveniently; The exhaust hood installation frame 6 described above is fixed on the cooling outlet of the ultra-low temperature freezer by screws, rivets or adhesives, and the exhaust installation frame 6 surrounds the entire cooling outlet. Such as figure 2 and image 3 As shown, the exhaust hood 5 is detachably installed on the exhaust hood installation frame 6 through a hook device, and the hook device includes a hook 8 and a hook groo...

Embodiment 2

[0026] The difference between the second embodiment and the first embodiment is that the exhaust fan 1 is connected with a plurality of exhaust hoods 5, and the controller 2 is connected with a plurality of sensors 7, that is, each ultra-low temperature freezer Both are equipped with an exhaust hood 5 and a sensor 7, but multiple ultra-low temperature freezers in the same refrigerating room can share one exhaust fan 1 and one controller 2; To remove the cooling capacity of the air conditioner in the storage room, a solenoid valve 10 is installed between the exhaust hood 5 and the pipe connector 4 , and the solenoid valve 10 is electrically connected to the controller 2 through an IO interface. The solenoid valve 10 is in the closed state before the power is turned on. When a certain sensor 7 receives the signal, it will transmit the signal to the controller 2. The controller 2 controls the exhaust fan 1 to work, and at the same time, it is powered on. Solenoid valve 10, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com