Hair removal wax and preparation method thereof

A technology of depilatory wax and paraffin wax, which is applied in the fields of hair removal, hair care, and pharmaceutical formulations. It can solve the problems of high melting point temperature of depilatory wax and easily cause burns, etc., and achieve the effects of low production cost, safe and reliable use, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

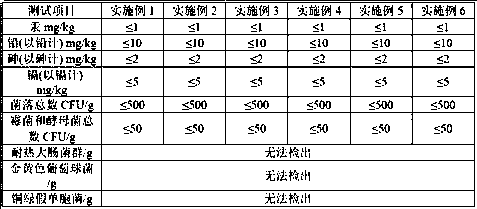

Examples

preparation example Construction

[0037] In one embodiment, the preparation method of the depilatory wax at least includes the following steps:

[0038] Step S01. Prepare the thickener, mixed film-forming agent (hydrogenated rosin, glycerol hydrogenated rosinate, ethylene-vinyl acetate copolymer), emollient, adhesive, and moisturizer according to the depilatory wax formula described above ;

[0039] Step S02. Mixing the prepared emollient and adhesive with the moisturizing agent, and heating to dissolve the emollient and adhesive in the moisturizing agent to obtain a first mixed solution;

[0040] Step S03. Add the thickener and film-forming agents other than ethylene-vinyl acetate copolymer to the first mixed solution, and heat to 120°C, so that the thickener and film-forming agents except ethylene-vinyl acetate copolymer The complete solvent of the film-forming agent other than the substance obtains the second mixed solution;

[0041] Step S04. Add the ethylene-vinyl acetate copolymer to the second mixed s...

Embodiment 1

[0051] A depilatory wax, comprising the following components in mass percentage:

[0052] Rosin 60.0%;

[0053] Hydrogenated rosin 10.0%;

[0054] Glyceryl Hydrogenated Rosinate 2.0%;

[0055] Ethylene-vinyl acetate copolymer 7.0%;

[0056] White beeswax 10.0%;

[0057] 40# paraffin 10.0%;

[0058] Mineral Oil 1.0%.

[0059] The preparation method of described depilatory wax, comprises the following steps:

[0060] The white beeswax and 40# paraffin are dissolved in the mineral oil to obtain the first mixed solution;

[0061] adding rosin, hydrogenated rosin, and glycerol hydrogenated rosinate to the first mixed solution, and heating to 120° C. to completely dissolve the rosin, hydrogenated rosin, and glycerol hydrogenated rosinate to obtain a second mixed solution;

[0062] Add ethylene-vinyl acetate copolymer to the second mixed solution, stir until uniform, and then homogenize to obtain depilatory wax;

[0063] The depilatory wax is granulated at 120° C., cooled to ...

Embodiment 2

[0065] A depilatory wax, comprising the following components in mass percentage:

[0066] Rosin 30.0%;

[0067] Hydrogenated Rosin 2.0%;

[0068] Glyceryl Hydrogenated Rosinate 15.0%;

[0069] Ethylene-vinyl acetate copolymer 10.0%;

[0070] White Beeswax 5.0%;

[0071] 45# paraffin wax 30.0%;

[0072] Mineral oil 8.0%.

[0073] The preparation method of described depilatory wax, comprises the following steps:

[0074] The white beeswax and 45# paraffin are dissolved in the mineral oil to obtain the first mixed solution;

[0075] adding rosin, hydrogenated rosin, and glycerol hydrogenated rosinate to the first mixed solution, and heating to 120° C. to completely dissolve the rosin, hydrogenated rosin, and glycerol hydrogenated rosinate to obtain a second mixed solution;

[0076] Add ethylene-vinyl acetate copolymer to the second mixed solution, stir until uniform, and then homogenize to obtain depilatory wax;

[0077] The depilatory wax is granulated at 110° C., cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com