Non-rivet riveting device and method for carbon fiber composite material and aluminum alloy

A rivetless riveting and composite material technology, which is applied in the field of composite material riveting, can solve the problems of matrix cracking, fiber breakage, and low joint performance, and achieve the effects of improving tensile strength, reducing damage, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

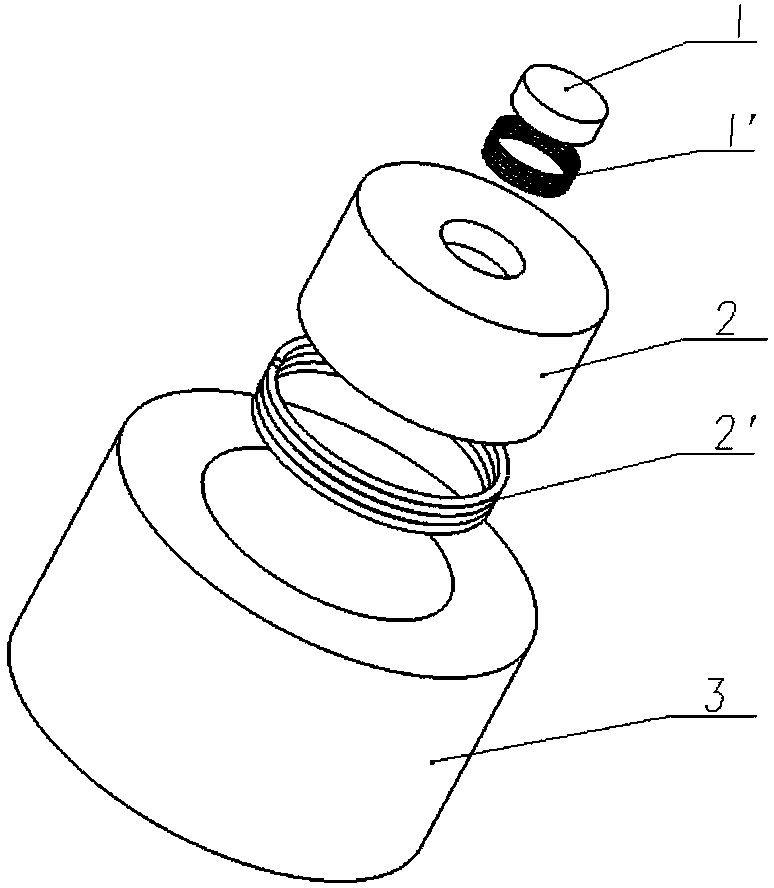

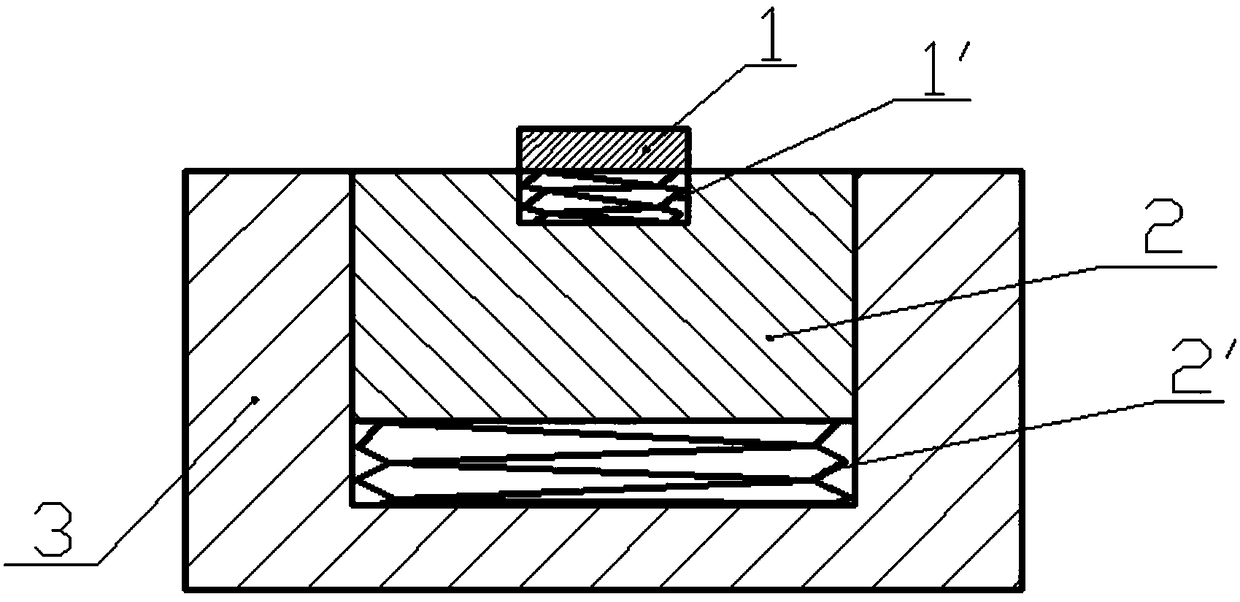

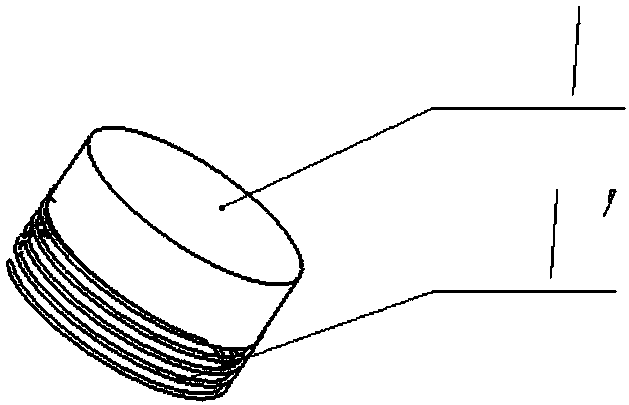

[0057] See attached Figure 1-9 The rivetless riveting device between carbon fiber composite material and aluminum alloy of the present invention includes a blank holder 6, a punch 7 and a die; the die includes a spring pad I1, a spring pad II2, a spring I1', a spring II2' and a lower mod 3;

[0058] A through hole for positioning the punch 7 is arranged at the structural center of the blank holder 6, and the punch 7 moves up and down in the through hole of the blank holder 6 during the riveting process;

[0059] The punch 7 is an integrated structure, including a needle body and a needle head; the needle body is cylindrical, the needle head is a circular truncated shape, and the side of the needle head circular pedestal has a small inclination angle, all inclined towards the center line of the needle body; The arc surface transition is adopted between the needle body and the needle head, and the arc surface transition is also adopted between the top surface and the side of t...

Embodiment 2

[0103] The method for realizing the rivetless riveting device between the carbon fiber composite material and the aluminum alloy by applying the above-mentioned device includes the following steps:

[0104] Step 1: cutting a through hole with a diameter of 8 mm in the center of the carbon fiber composite material plate 4 by a numerical control CNC machine tool;

[0105]Step 2: Place the carbon fiber composite material plate 4 and the aluminum alloy 5 with a through hole of 8 mm in step 1 on the die in sequence from bottom to top, punch 7, blank holder 6, carbon fiber composite material plate through hole and The die is placed concentrically, and the blank holder 6 is driven to move down until the carbon fiber composite material plate 4 and the aluminum alloy plate 5 are pressed;

[0106] Step 3: Put the punch 7 into the fixture of the riveting machine and lock it, then start the riveting machine, send the punch 7 into the center positioning through hole of the blank holder 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com