Device of multi-field coupling refined metal solidification structure and refining process thereof

A technology of metal solidification and organization, which is applied in the field of metal material processing, can solve the problems of single metal melt refinement treatment technology, and achieve the effects of shortening processing time, refining grains, and promoting nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Taking the refinement of hypereutectic high-chromium cast iron (liquidus at 1337°C and solidus at 1276°C) solidification structure as an example, combined with the refinement process of multi-field coupling to refine the solidification structure of metal, further describe:

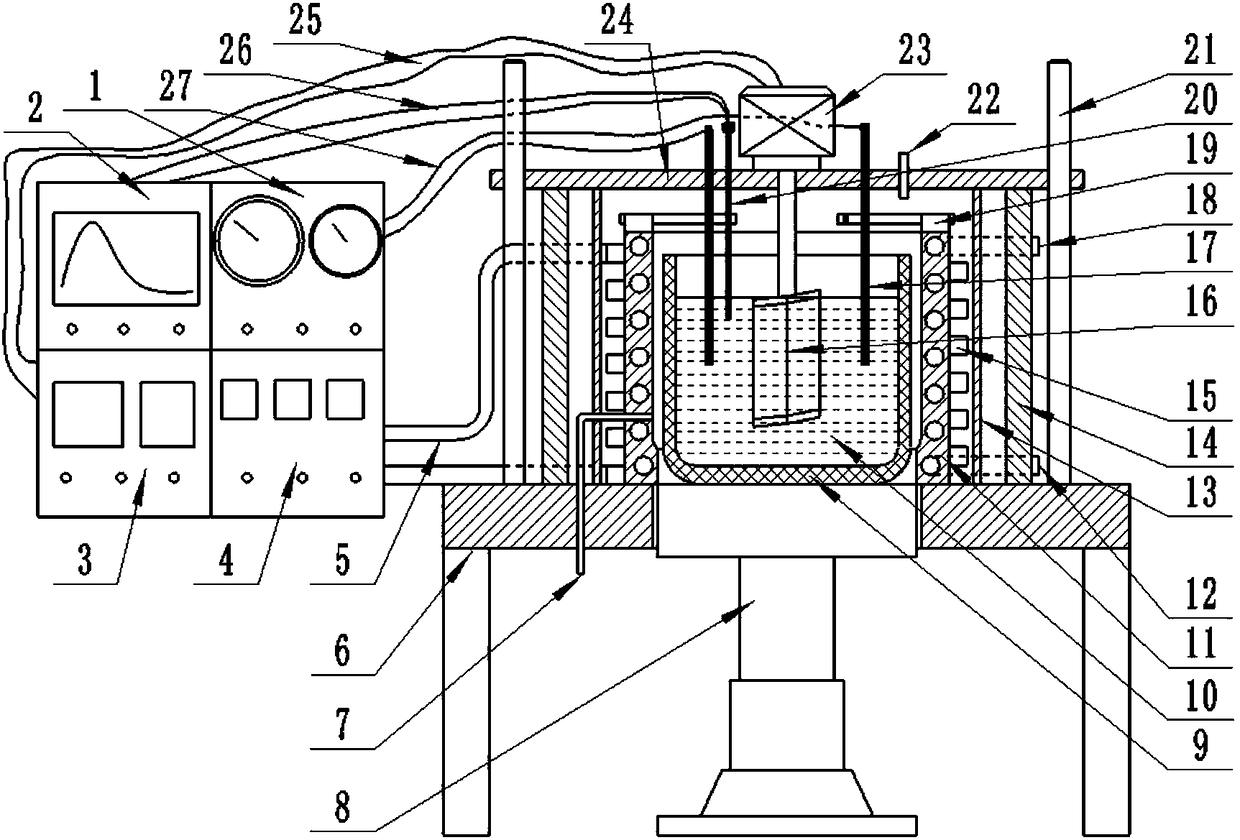

[0036] Such as figure 1 As shown, the hypereutectic high chromium cast iron is loaded into the crystallizer 9, the crystallizer 9 is installed on the lifter 8, and the lifter 8 is lifted into the cooling cover 11 through the base 6, and the lifter 8 fixes the crystallizer 9 The part closely fits with the cooling cover 11; the electrode 17 and the thermocouple 20 are installed on the sealing cover 24, positioned or fixed by the bracket 19, the motor 23 is connected to the stirring rod 16 and installed on it, and the electrode 17, the thermocouple 20 and the The position of the motor 23, the sealing cover 24 descends through the guide post 21 and closely cooperates with the sealing cover 14, the argon...

Embodiment 2

[0038] The following takes the refinement of Cu-10%Sn alloy (the liquidus is 1021°C and the solidus is 830°C) as an example, combined with the refinement process of multi-field coupling refinement of metal solidification structure for further description:

[0039] Such as figure 1 As shown, the Cu-10% Sn alloy is loaded into the crystallizer 9, the crystallizer 9 is installed on the lifter 8, and the lifter 8 is lifted into the cooling cover 11 through the base 6, and the lifter 8 fixes the crystallizer 9 The part is tightly matched with the cooling cover 11; the electrode 17 and the thermocouple 20 are installed on the sealing cover 24, positioned or fixed by the bracket 19, the motor 23 is connected to the stirring rod 16 and installed on it, and the electrode 17, the thermocouple 20 and the motor are adjusted 23 position, the sealing cover 24 descends through the guide post 21 and closely cooperates with the sealing cover 14, the argon gas is introduced through the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com