A single-doped-enriched core-shell structure up-conversion luminescent material and its preparation method

A technology of core-shell structure and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, nanotechnology, etc., can solve the problems of no significant improvement, difficulty in meeting the harsh requirements of industrial production, instruments and equipment, etc., and achieve high-efficiency luminescence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

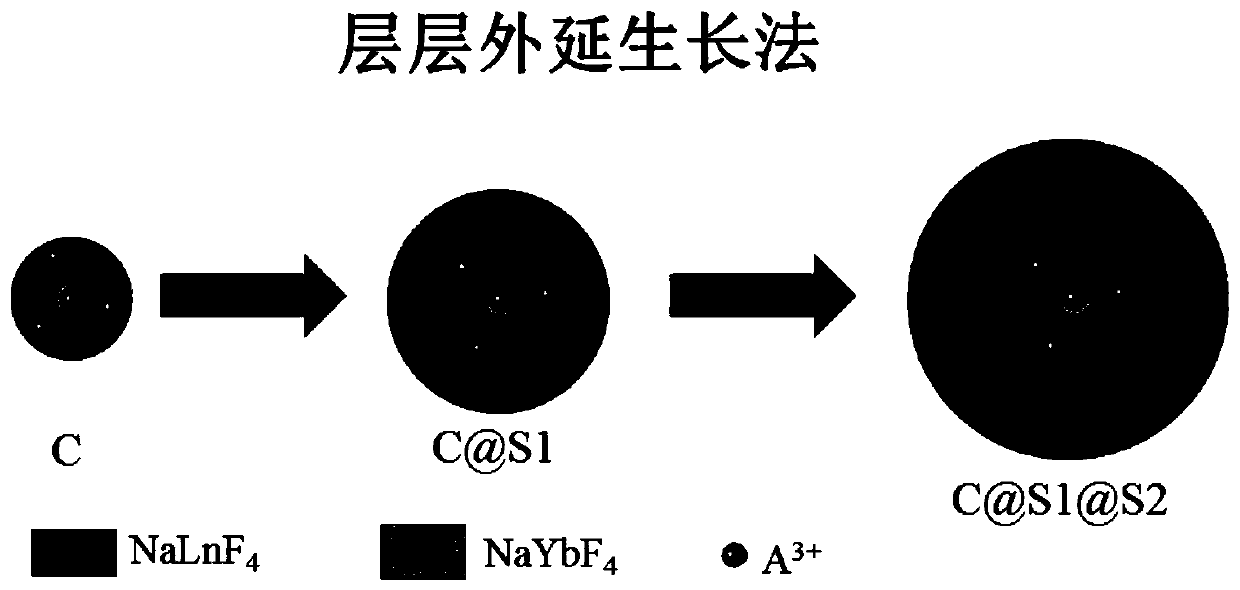

Method used

Image

Examples

Embodiment 1

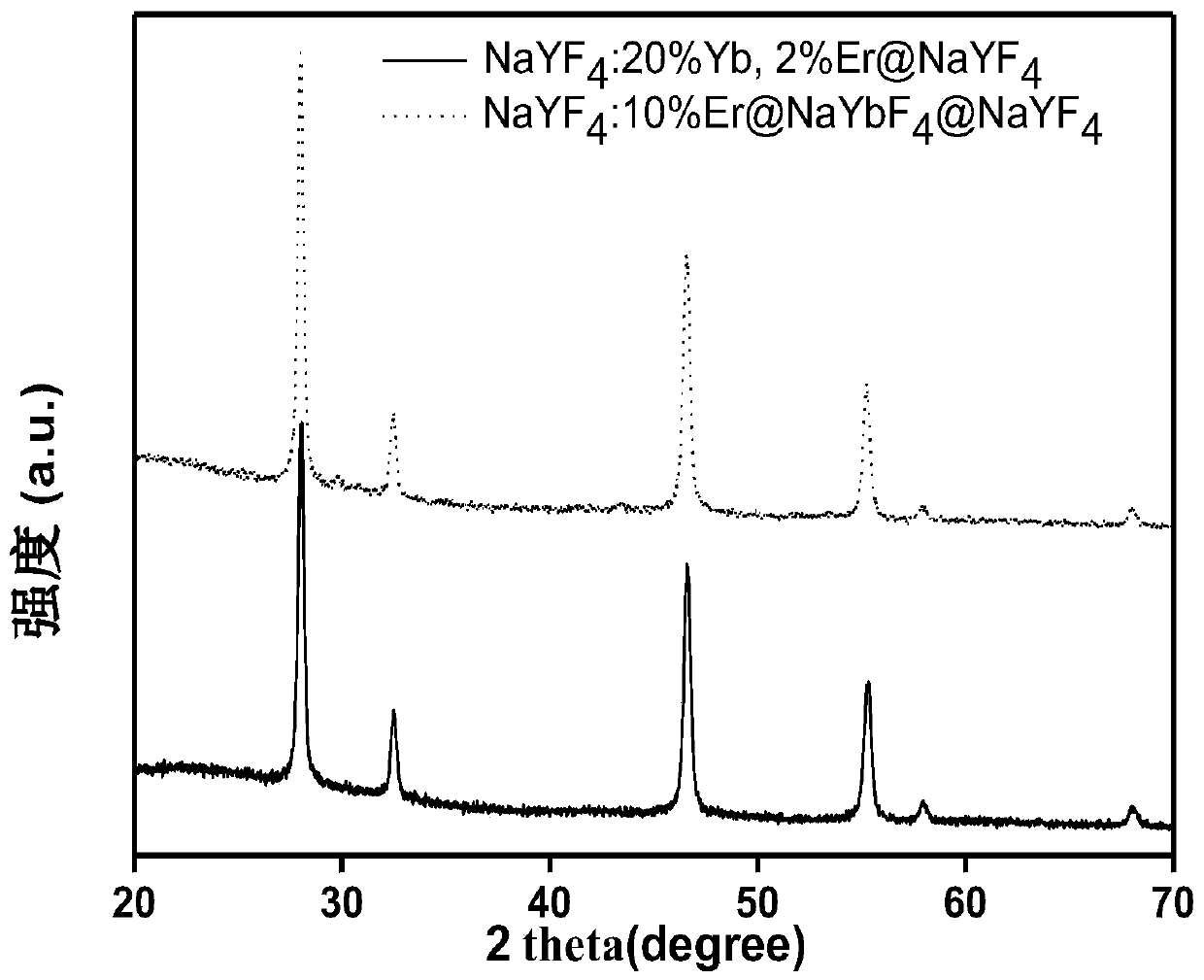

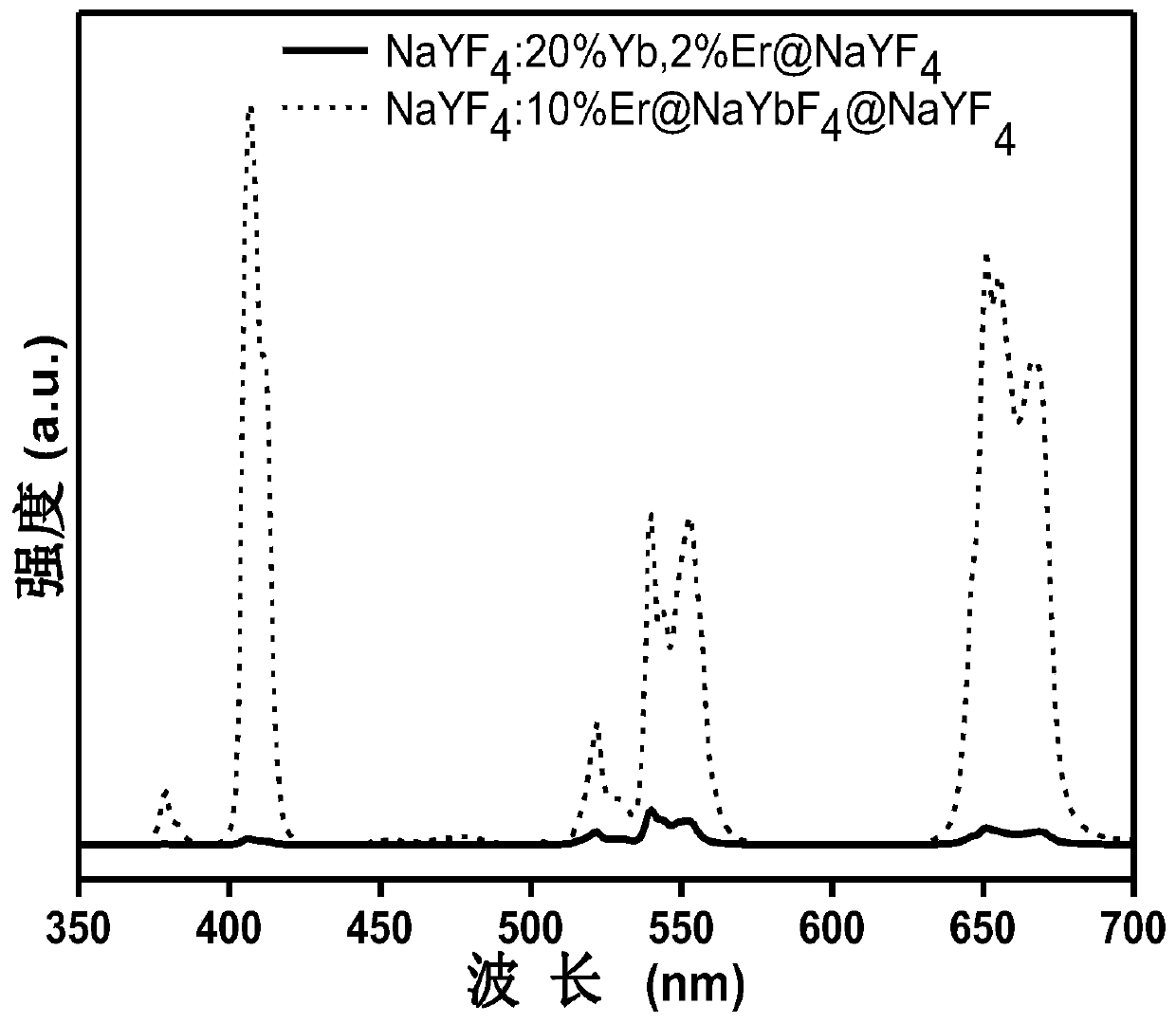

[0043] NaYF 4 :10%Er 3+ @NaYbF 4 @NaYF 4 preparation of

[0044] Step 1: NaYF 4 :10%Er 3+ Synthesis of C-nuclear nanomaterials: 0.9 mmol of Y-TFA and 0.1 mmol of Er-TFA in ethanol and 1 mmol of Na-TFA in ethanol were mixed, and ethanol was removed under argon flow at 120°C for 40 minutes to obtain trifluoroacetate Powder; add 8ml of oleic acid and 12ml of octadecene solvent under the Ar flow at room temperature, rise to 200°C for rapid dissolution, and cool down to room temperature; switch to Ar flow and remove water at 170°C for 40 minutes, then heat up to 270°C for 13 minutes, Incubate for 20 minutes, and after natural cooling, centrifuge twice with ethanol and place in 10ml cyclohexane.

[0045] Step 2: NaYF 4 :10%Er 3+ @NaYbF 4 Synthesis of C@S1-core-shell nanomaterials: Take 3ml of C-cyclohexane dispersion for core-shell structure synthesis. Take 1 mmol of Yb-TFA ethanol solution and 1 mmol of Na-TFA ethanol solution, remove ethanol for 30 minutes under argon fl...

Embodiment 2

[0050] NaYF 4 :50%Er 3+ @NaYbF 4 @NaYF 4 preparation of

[0051] Step 1: NaYF 4 :50%Er 3+ Synthesis of C-nuclear nanomaterials: 0.5mmol Er-TFA ethanol solution, 0.5mmol Y-TFA ethanol solution and 1mmol Na-TFA ethanol solution were mixed, and ethanol was removed under argon flow at 120°C for 30min to obtain trifluoro Acetate powder; add 8ml of oleic acid and 12ml of octadecene solvent under the Ar flow at room temperature, rise to 200°C for rapid dissolution, and then cool down to room temperature; switch to argon flow and remove water at 170°C for 30 minutes, then heat up to 270°C, keep warm for 16min, after natural cooling, centrifuge twice with ethanol, and place in 10ml cyclohexane.

[0052] Step 2: NaYF 4 :50%Er 3+ @NaYbF 4 Synthesis of C@S1-core-shell nanomaterials: Take 3ml of C-cyclohexane dispersion for core-shell structure synthesis. Take 1 mmol of Yb-TFA ethanol solution and 1.5 mmol of Na-TFA ethanol solution, remove ethanol at 120°C for 30 minutes under a...

Embodiment 3

[0056] NaGdF 4 :10%Er 3+ @NaYbF 4 @NaGdF 4 preparation of

[0057] Step 1: NaGdF 4 :10%Er 3+ C-Synthesis of nuclear nanomaterials: Mix 0.9 mmol of Gd-TFA and 0.1 mmol of Er-TFA in ethanol and 2 mmol of Na-TFA in ethanol, remove ethanol at 170°C for 20 minutes under argon flow to obtain trifluoroacetate powder; Add 4ml of oleic acid and 6ml of octadecene solvent under the Ar flow at room temperature, rise to 160°C for rapid dissolution, and then cool down to room temperature; switch to Argon flow and remove water at 120°C for 30 minutes, then raise the temperature to 320°C for 13 minutes, and keep warm for 16 minutes , after cooling naturally, centrifuge twice with ethanol and place in 10ml cyclohexane.

[0058] Step 2: NaGdF 4 :10%Er 3+ @NaYbF 4 Synthesis of C@S1-core-shell nanomaterials: Take 3ml of C-cyclohexane dispersion for core-shell structure synthesis. Take 1 mmol of Yb-TFA ethanol solution and 1.5 mmol of Na-TFA ethanol solution, remove ethanol at 120°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com