Reinforced prefabricated direct-buried insulation pipe

A technology of prefabricated direct-buried and heat-insulated pipes, applied in the direction of protecting pipes by heat insulation, heat preservation, and pipe protection, etc., can solve the problems of corrosion of steel pipes, poor sealing of exhaust holes, broken outer protective pipes of heat preservation elbows, etc. Service life, the effect of guaranteeing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

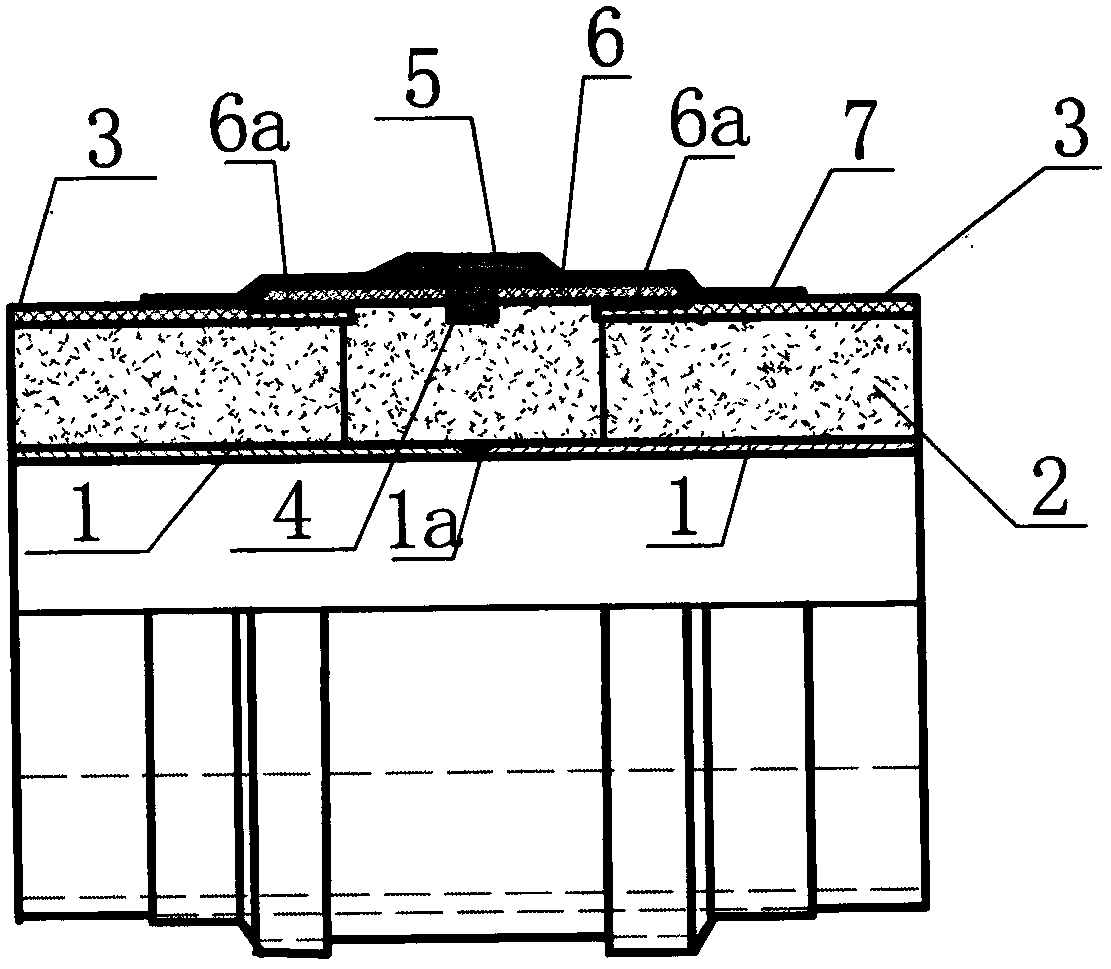

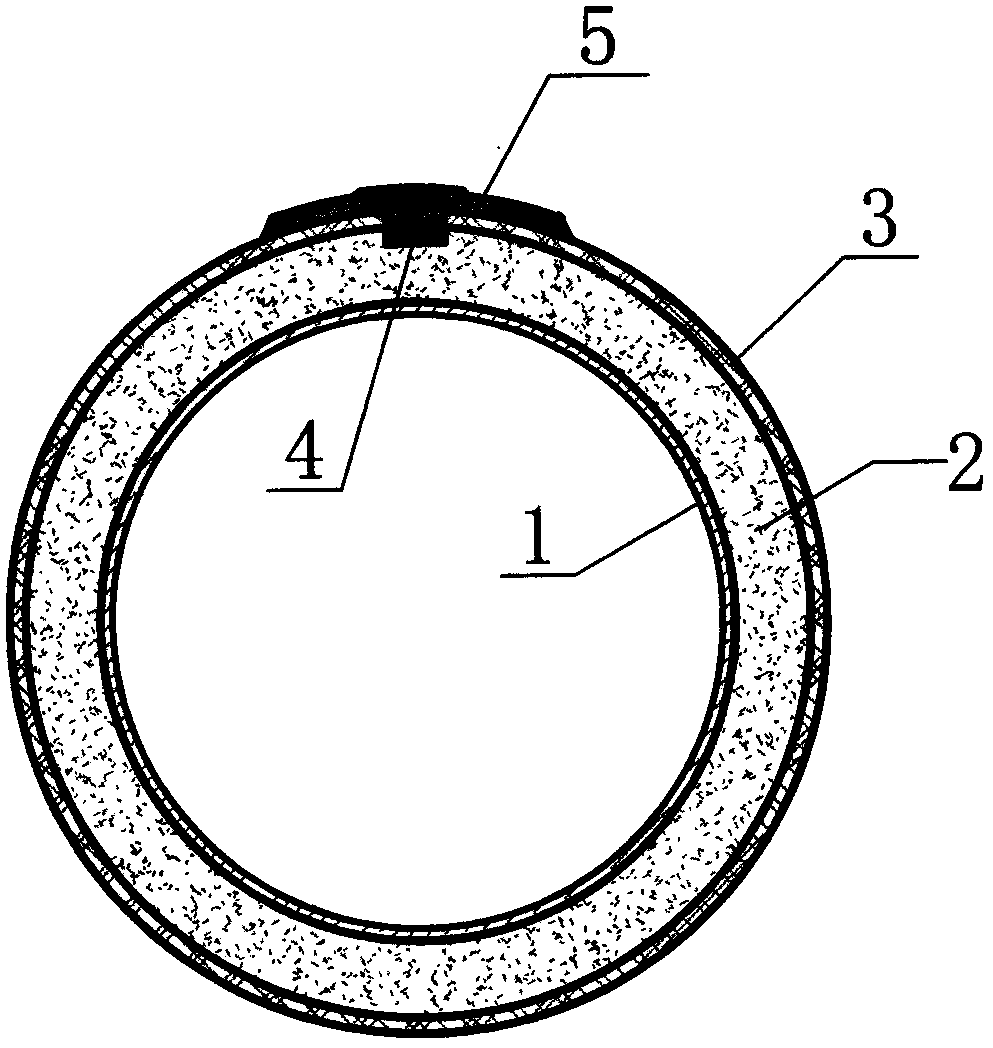

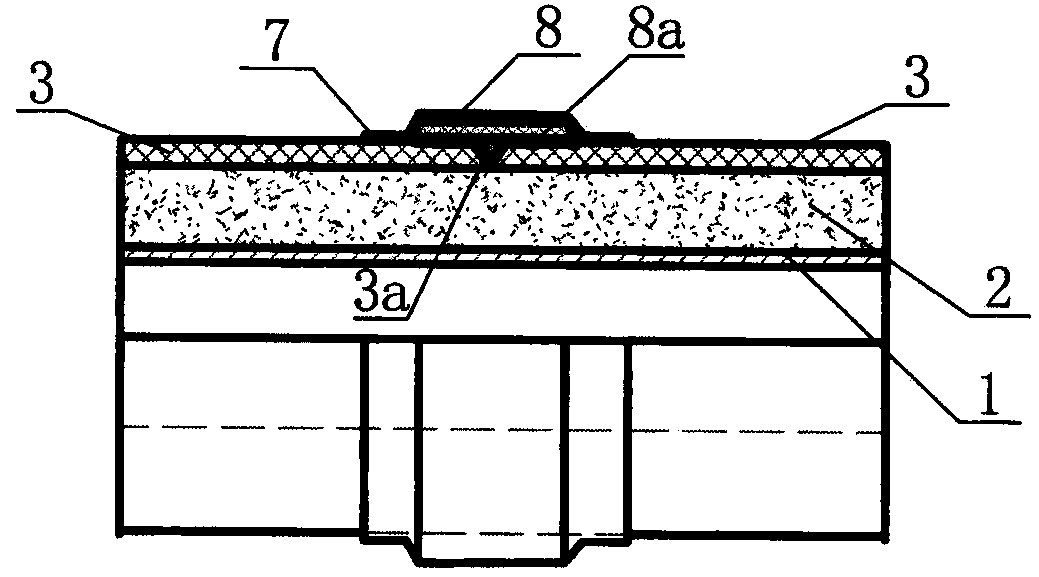

[0025] Taking a certain project as an example, the original design plan is: the pressure of the water supply and return pipe is 2.5MPa, the operating temperature is 135°C / 65°C; the double pipes are laid in the same ditch, all the technical parameters of the water supply pipe and the return pipe are the same, and the steel pipe specification is D1020*14 / PE The outer protective pipe D1155*15, the minimum density of the foam insulation layer is not less than 60KG / m3; the long-term temperature resistance of the foam is not lower than 140°C; in the insulation pipe fittings, only the bending diameter of the insulation elbow is required, and the insulation joints and other There are no specific technical requirements for technical details such as thermal insulation pipe fittings and injection hole sealing.

[0026] Based on the principle of equal-life optimization design, after consultation with the owner and the consent of the original designer, we take the following reinforcement me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com