Triplex backup temperature measurement sensor

A technology of temperature measurement sensor and temperature sensor, which is applied in the direction of instruments, thermometers, measuring devices, etc., can solve the problems of increased cost, weight of the entire test system, large measurement error, high cost of four-wire platinum resistance sensor, etc., and achieve shock resistance Good, reduced volume and weight, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

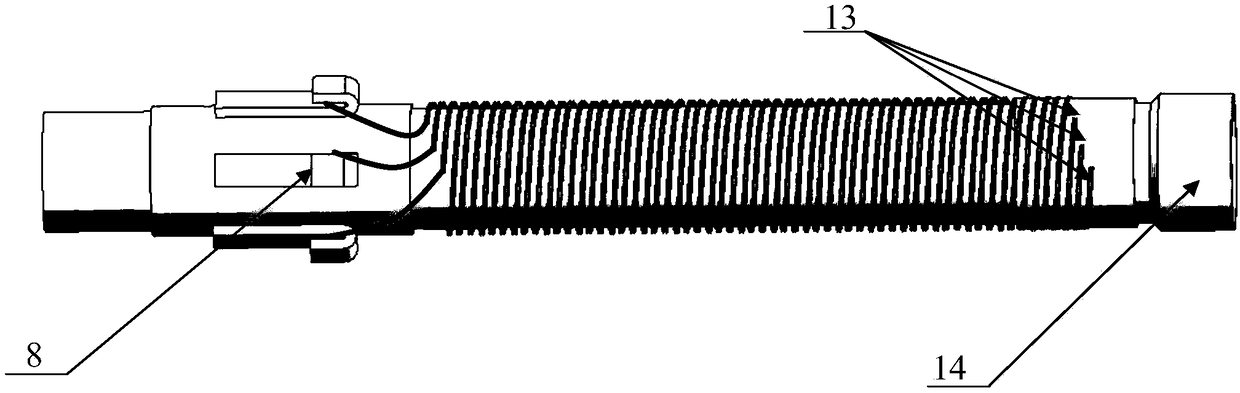

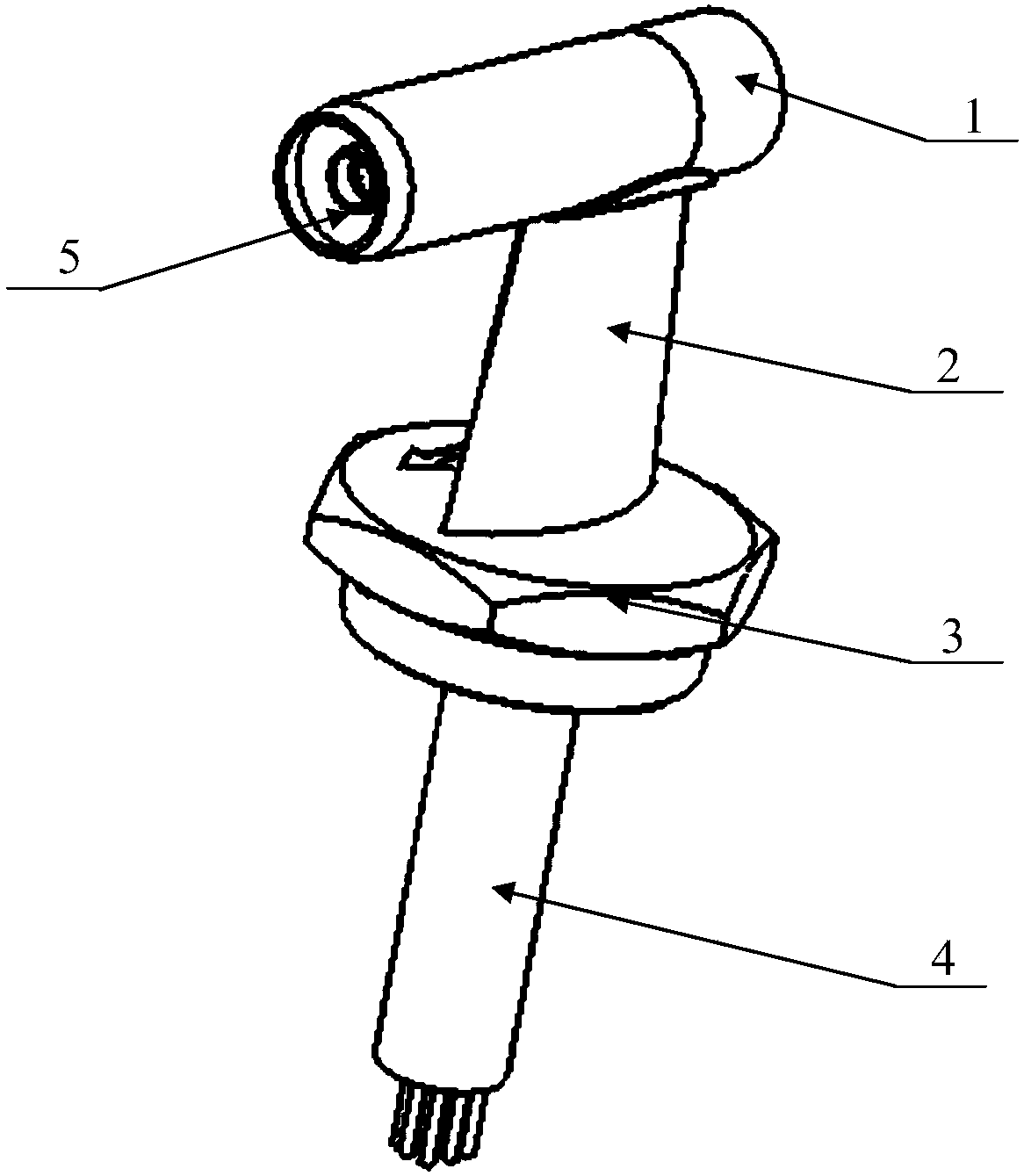

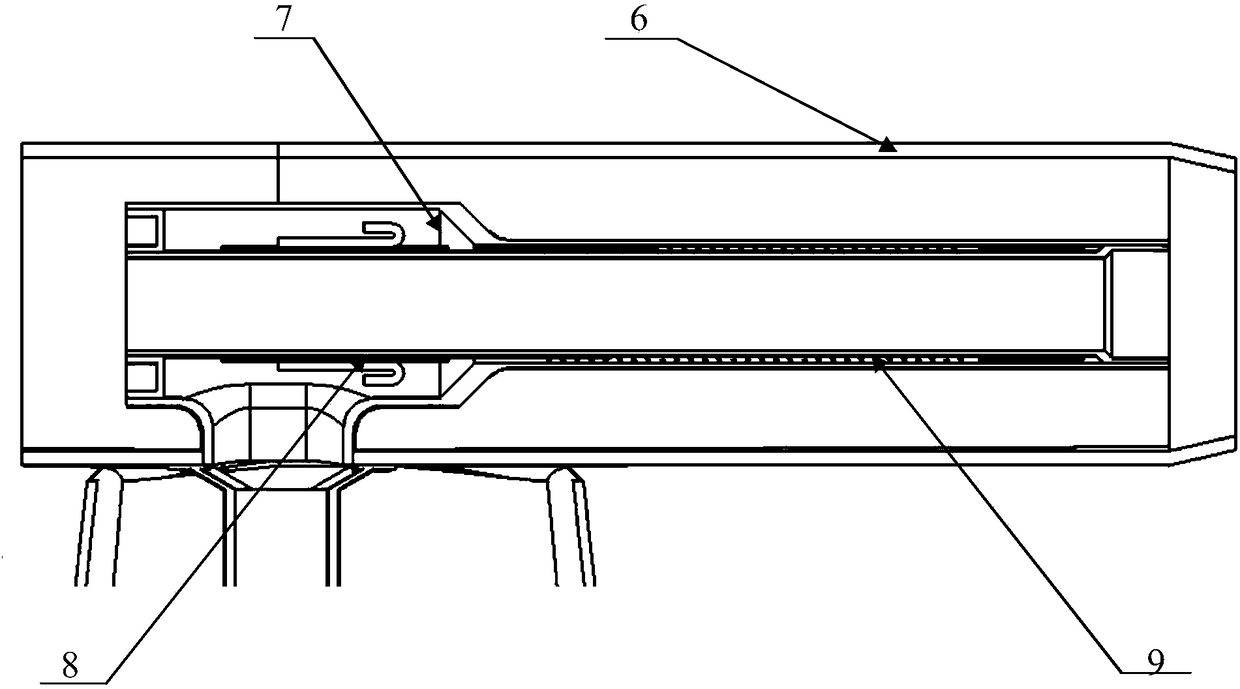

[0019] refer to Figure 1-Figure 4 . In the embodiment described below, a triple backup temperature measuring sensor includes: a temperature sensing sensor 1 and a cable sleeve 4 fixedly connected to the body of a threaded connection plate 3 through a streamlined bracket 2 . The inner tube of the double-layer sealed semiconductor probe 9 of the coaxially connected temperature sensor 1 passes through the heat insulation layer, passes through the metal throat 7 of the temperature sensor 1, is fixedly connected to the rear end tail cover, and is encapsulated in the metal outer tube 6 In the mutually independent air flow channels, the curved lug 8 is elastically attached to the cylindrical surface of the double-layer sealed semiconductor probe 9, and connected to the measuring end of the secondary coil winding tap of the signal toroidal transformer, and the coil winding taps are respectively connected through the curved lug 8 The wire 10 of the cable sleeve 4 outputs a signal; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com