A method for continuous monitoring and control of cased well fracturing based on well-ground potential imaging

A monitoring and control, geopotential technology, applied in wellbore/well components, electrical/magnetic exploration, geophysical measurement, etc. The number of electrodes is small, the azimuth resolution is low, etc., to achieve the effect of improving accuracy, low usage, and increasing the amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

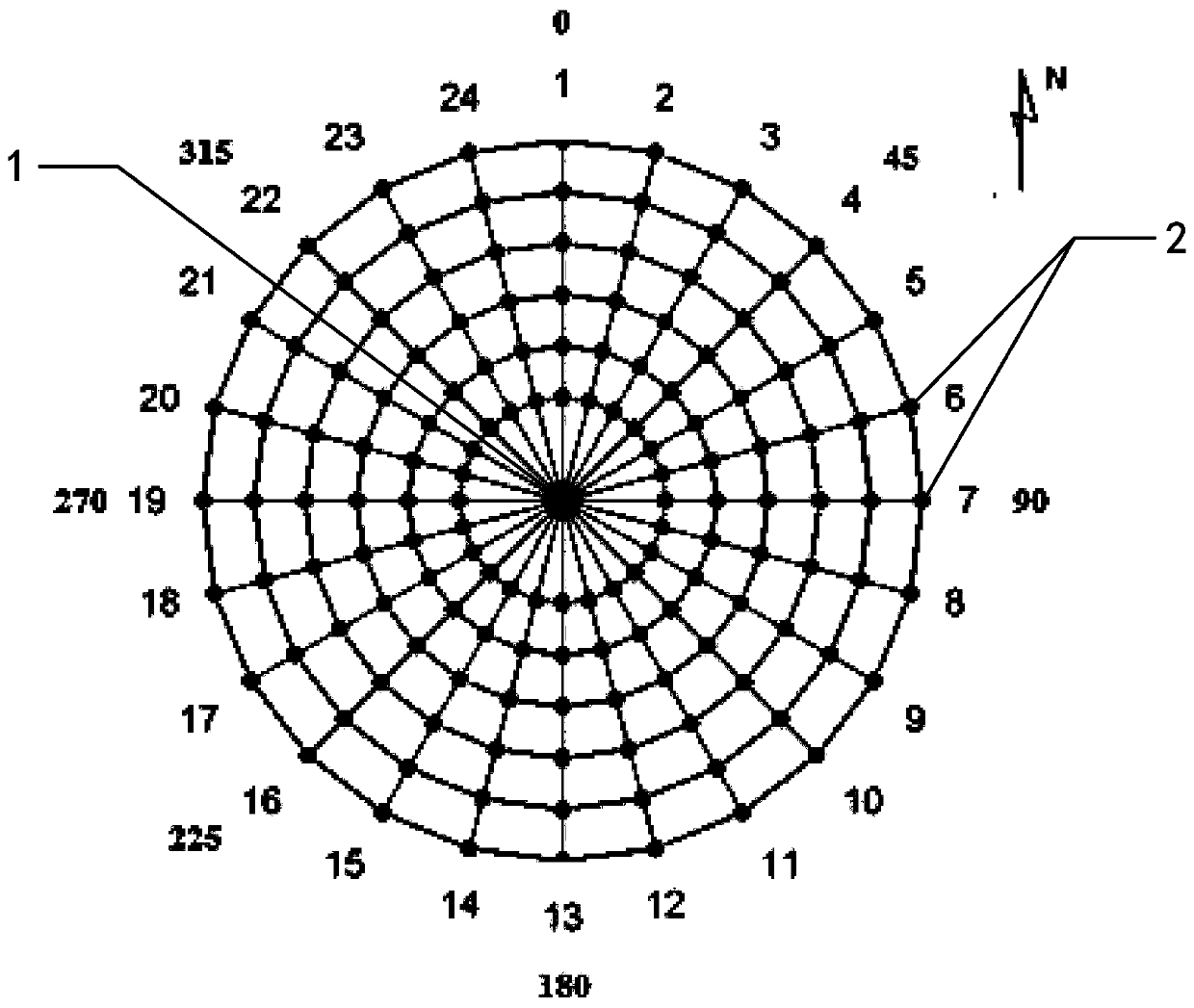

[0025] This example presents a method of measuring point layout for a cased well fracturing continuous monitoring and control method based on well-ground potential imaging, as shown in figure 1 As shown, with the measured cased well 1 as the center of the circle, radial measuring points 2 are arranged circularly on the ground. The arrangement of the measuring points 2 is 6 ring measuring points, the radius of each ring is 50 meters, 100 meters, 150 meters, 200 meters, 250 meters, 300 meters, and the angle between two adjacent measuring points in each ring is 15 degrees, 24 measuring points are arranged in each ring. The casing of the measured cased well 1 is connected to a power supply, and the measuring point is provided with a potential acquisition device for measuring the potential of the measuring point, and the potential data of the measuring point is sent to the data processing and analysis device at the back end by wired or wireless means .

Embodiment 2

[0027] This embodiment provides a method for continuous monitoring and control of cased well fracturing based on well-ground potential imaging, including the following steps:

[0028] 1. With the measured cased well as the center of the circle, radial measuring points are arranged circularly on the ground. Refer to Embodiment 1 for the specific arrangement.

[0029] 2. Supply current downhole through the casing, start the fracturing process, and continuously measure and collect the data of the supplied current and the potential data of the measuring point. Specifically, the measurement point data can be collected at constant time intervals (for example, the whole process of fracturing is expected to be 1 to 2 hours, and the time interval is set to 1 to 10 minutes), and the time of said data collection should cover before starting fracturing and before injection. The whole process of fracturing is monitored and displayed in real time during the whole process of fracturing, suc...

Embodiment 3

[0035] This example shows the effect of fracturing the 3044.8-3008.8m well section of Well S141 using the method described in Example 2. During construction, the data is collected at intervals of 5 minutes, and the results are as follows:

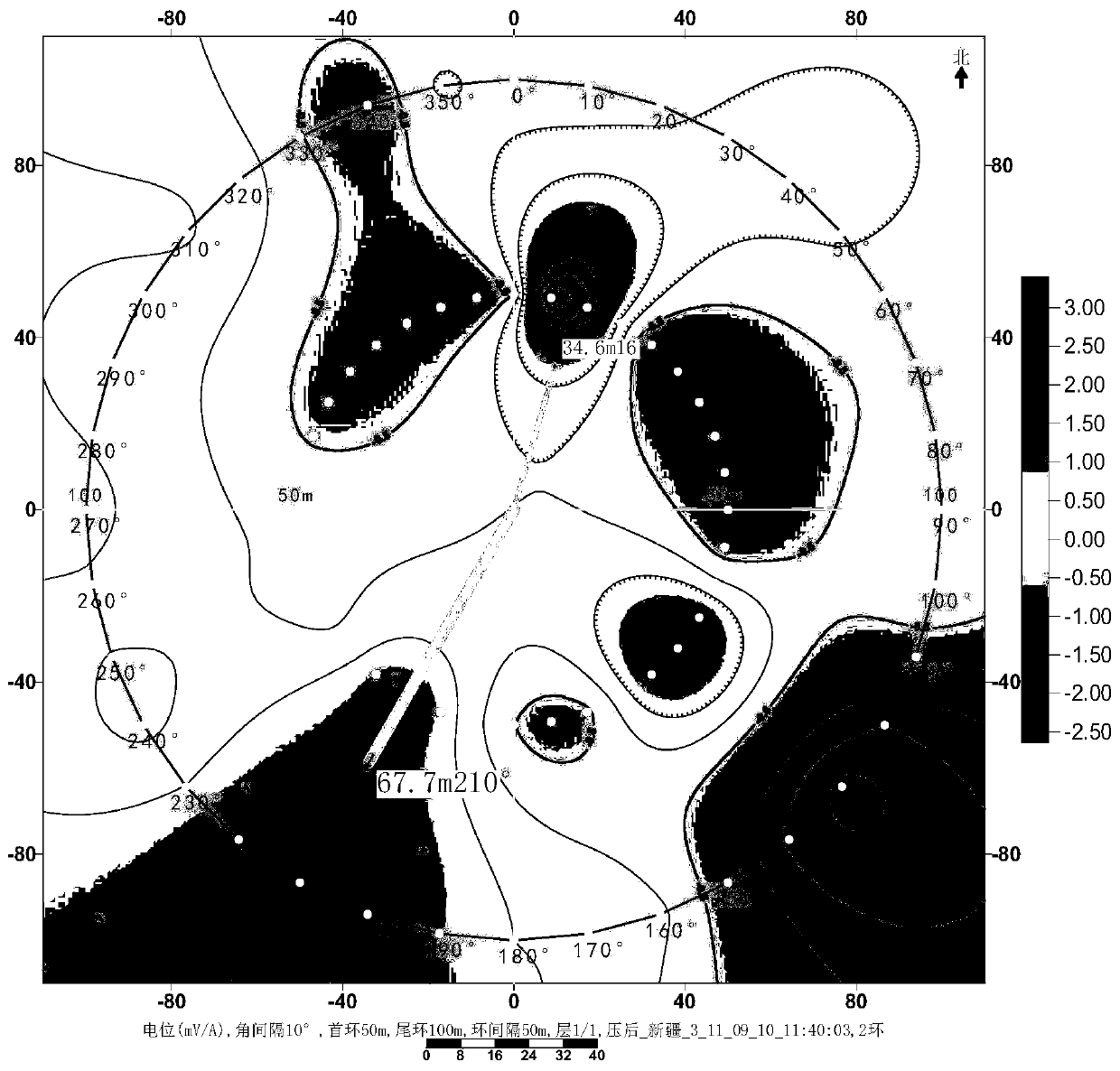

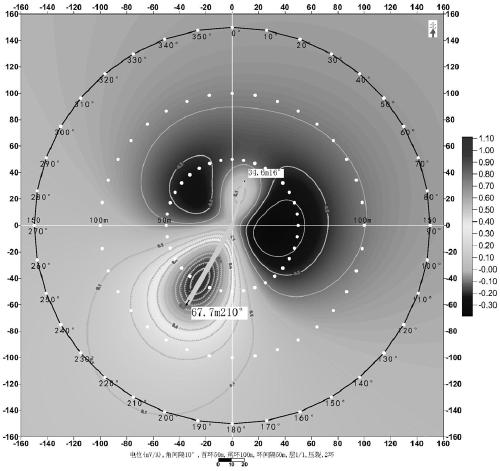

[0036] Figures 2 to 4 They are the potential measurement results of different rings before fracturing, after fracturing, and during fracturing (when sand-carrying fluid is injected). in, figure 2 and image 3 The potential imaging diagrams of the six rings before and after fracturing are shown respectively. It can be seen that the images before and after fracturing have obvious changes. There are fractures or abnormal development of permeable zones in one direction, and the imaging map after fracturing indicates that the south-south west is the main fracturing direction. Figure 4 It is the section view of the first ring and the second ring (ie, 50-meter ring and 100-meter ring) from the inside to the outside during fracturing (when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com