Experimental system and method for flammable gas explosion in a small-sized pipeline

An experimental system and gas explosion technology, applied in the field of flammable gas explosion experimental systems in small-sized pipelines, can solve problems such as leakage of radioactive substances, damage to containment, etc., and achieve high safety, low cost, and simple experimental steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

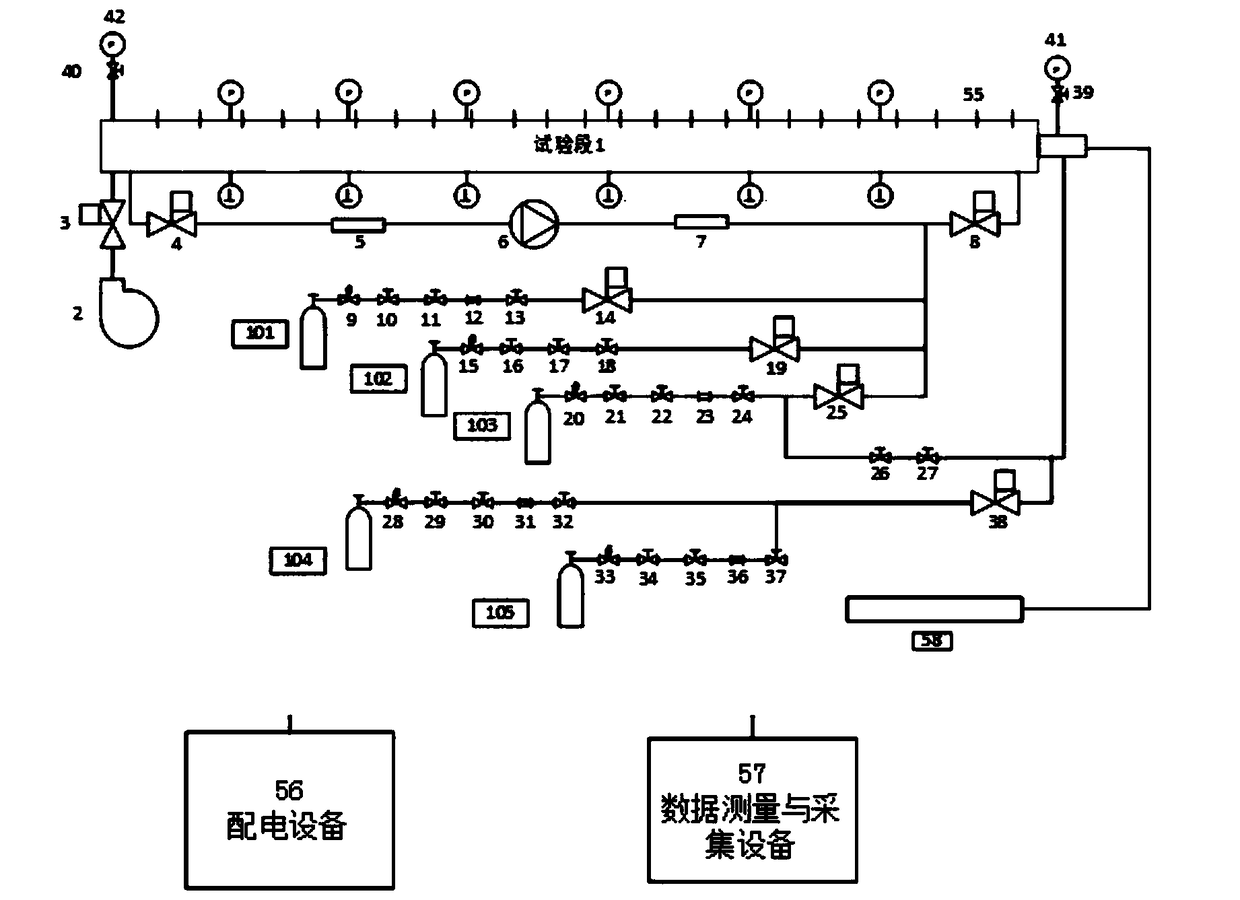

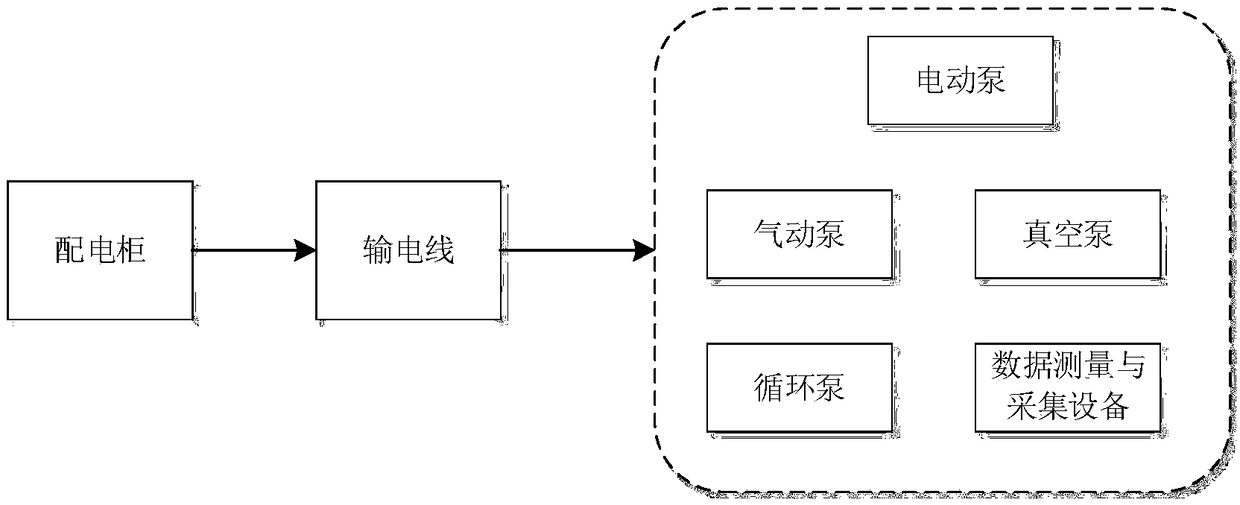

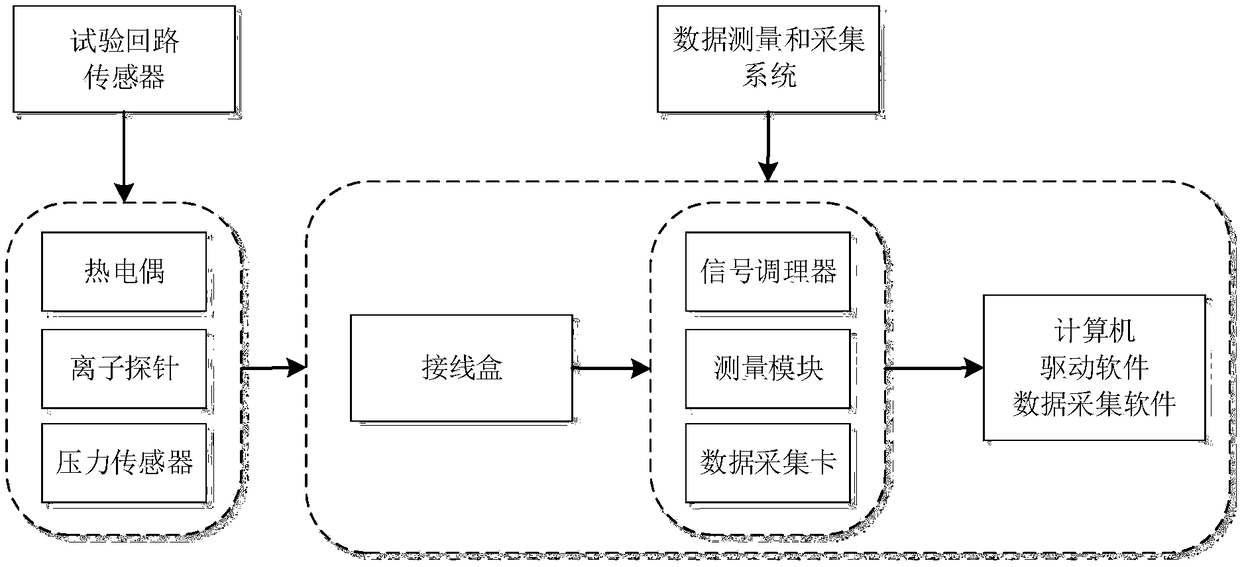

[0023] Such as figure 1As shown, the present invention is an experimental system for flammable gas explosion in a small-sized pipeline, which includes an experimental section 1, an acetylene detonating section connected to the experimental section 1 through a flange with the same inner diameter and wall thickness as the experimental section 1, and power distribution equipment 56 and data measurement and acquisition equipment 57; the ignition end of the acetylene detonation section is arranged with an opening for installing the ignition rod and connecting the ignition section pipeline, and a detonation section static pressure sensor 41 is arranged on the wall surface of the acetylene detonation section to detonate The section static pressure sensor 41 is connected to the ignition section through the detonation section static pressure valve 39; when needi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com