Rapid sewage discharge and precipitation device and method for rapid settlement and recovery

A rapid sewage discharge and rapid technology, applied in separation methods, chemical instruments and methods, settling tanks, etc., can solve the problems of long installation time, no need to have water first, or unable to build masonry, and many installation procedures, etc., to speed up The effect of cleaning time, speeding up the investment of pumping time, and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

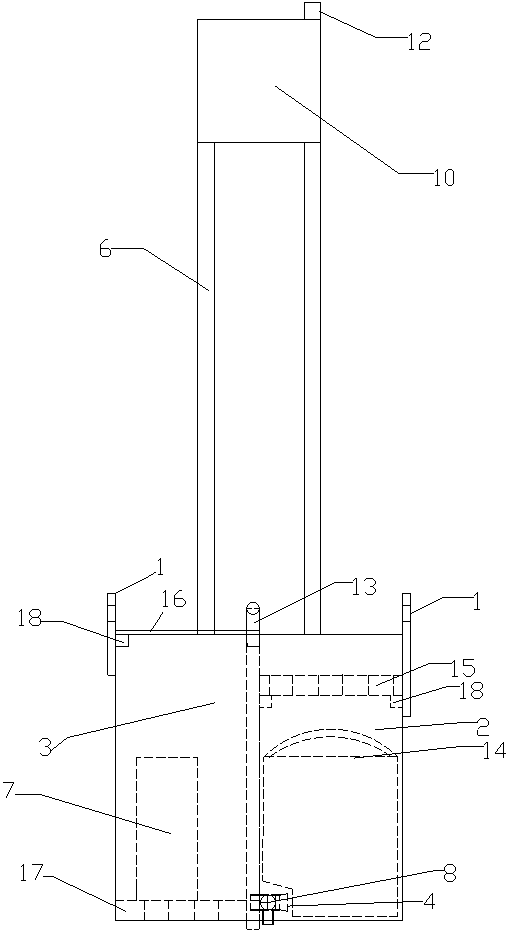

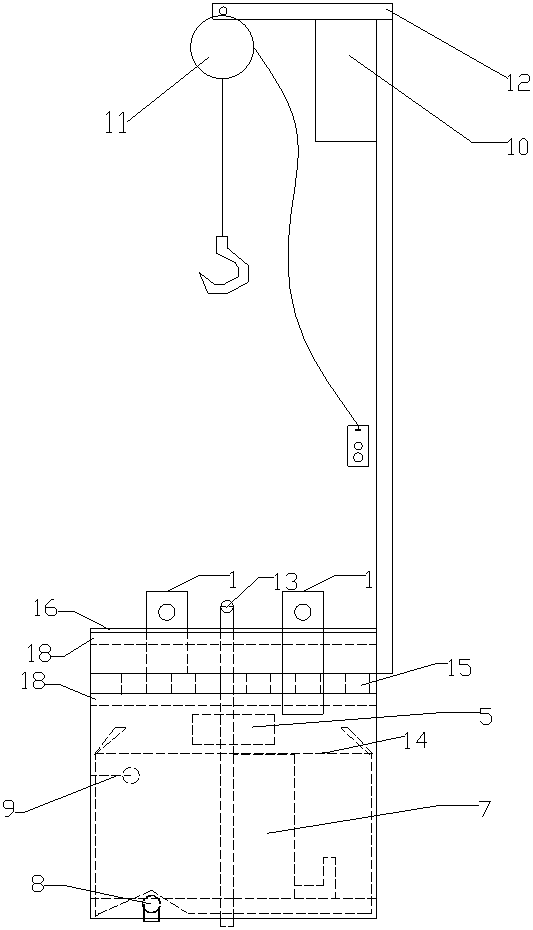

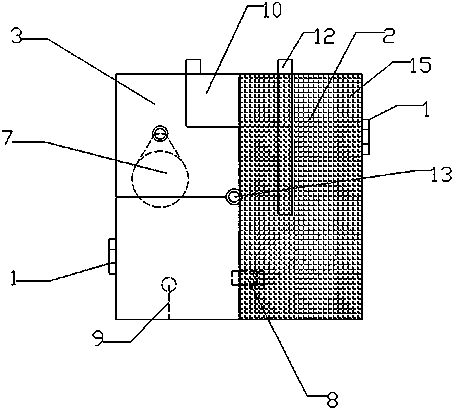

[0026] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-3 shown).

[0027] A rapid sewage discharge and precipitation device for rapid installation and recovery, which includes a 2-3 stage sedimentation tank box and a boom part;

[0028] The inside of the 2-3 level sedimentation tank box (the 2-3 level sedimentation tank box is a cuboid steel box structure) is divided into the third-level sedimentation tank 3 and the second-level sedimentation tank 2, and the third-level sedimentation tank The upper part (steel plate) between 3 and the secondary sedimentation tank 2 is connected through an overflow port 5; the bottom of the 2-3 sedimentation tank box is provided with a three-way valve 8, and the three ports of the three-way valve 8 are respectively connected to three Three-way valve 8 is provided with a three-way valve plug 4 on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com