Totally enclosed type magnetic separation system

A magnetic bead and magnetic field technology, applied in the field of magnetic separation, can solve the problems of poor applicability, pollution, false positives, etc., and achieve the effect of wide application range and avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

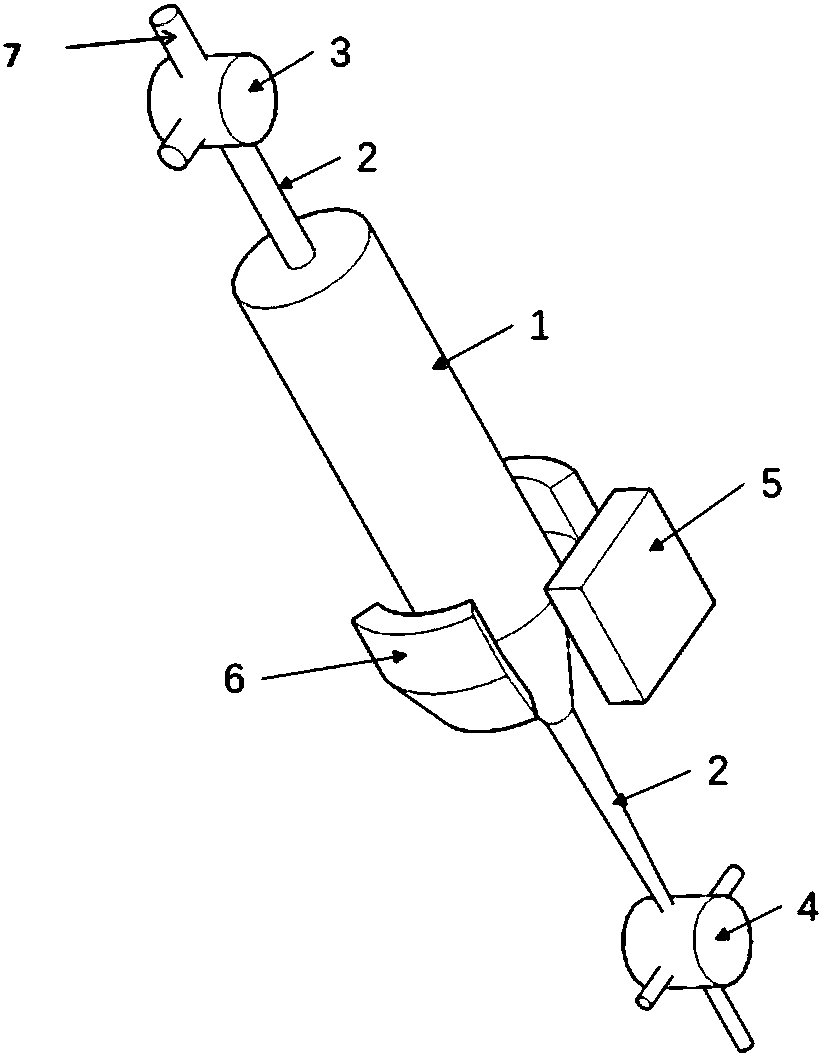

[0054] Such as figure 1 As shown, this embodiment provides a mixing device, which includes: a cavity 1 , a sample injection controller 3 , a sample outlet controller 4 , a magnet 5 and a mixer 6 .

[0055] Wherein, the shell of the cavity 1 is made of hard material, which is used to provide an operating space for mixing one or more sample liquids and magnetic beads. The sample liquid is various liquids such as a target solution containing a target substance and a solution containing surface-coated magnetic beads. The surface-coated magnetic beads are magnetic beads whose surface is coated with an adsorption substance for specific adsorption with a target substance. The average particle size of the magnetic beads is in the range of 0.01-100 microns. The cavity 1 is generally a combination of a cylindrical shape and a conical shape, but it can also be in other shapes.

[0056] The sample injection controller 3 is used to control the entry of the sample liquid, and has two ope...

Embodiment 2

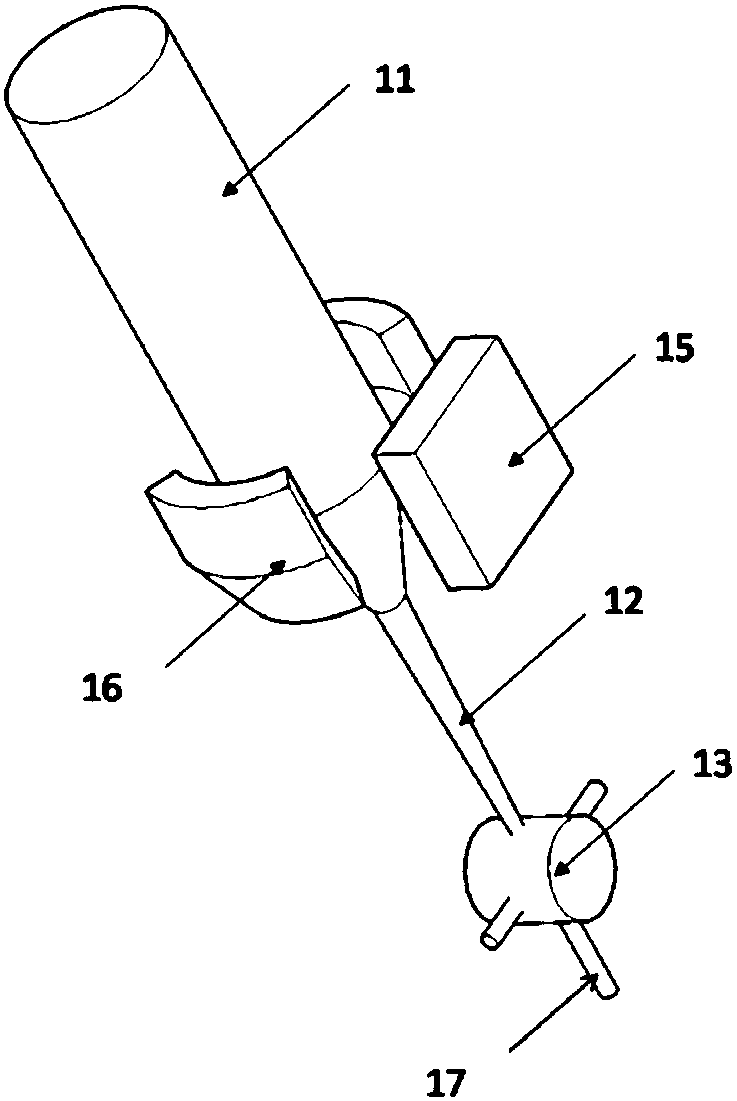

[0077] The sample inlet controller 3 and the sample outlet controller 4 of the mixing device in the first embodiment are separated, however, they can also be combined together. Such as figure 2 As shown, this embodiment provides a mixing device, which includes: a cavity 11 , a sample inlet and outlet controller 13 , a magnet 15 and a mixer 16 .

[0078] Wherein, the cavity 11 provides an operating space for mixing one or more sample liquids with the magnetic beads, and its shell is made of hard material. The sample liquid is various liquids such as a target solution containing a target substance and a solution containing surface-coated magnetic beads. The surface-coated magnetic beads are magnetic beads whose surface is coated with an adsorption substance for specific adsorption with a target substance. The average particle size of the magnetic beads is in the range of 0.01-100 microns. The cavity 11 is generally a combination of a cylindrical shape and a conical shape, bu...

Embodiment 3

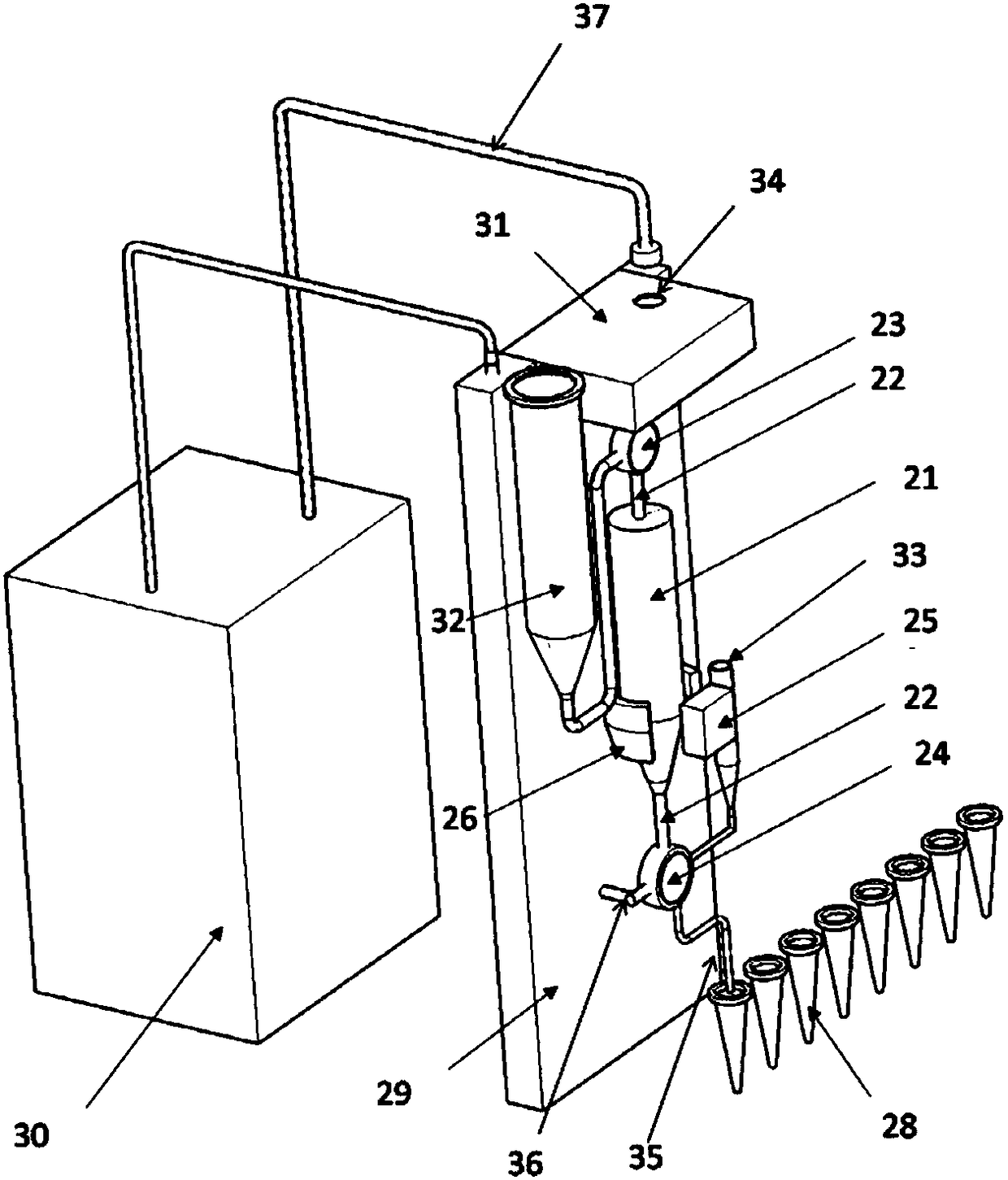

[0099] This embodiment provides a magnetic separation system, which includes: a cavity 21, a magnet 25, three sample injectors, a sample injection controller 23, a sample discharge controller 24, a mixer 26, a recovery device 29, and a drive device 30. Collection device 28.

[0100] Wherein, the cavity 21 is used for temporarily storing the sample liquid and providing an operation space for mixing the sample liquid and the magnetic beads, and its shell is made of hard material. The sample liquid is various liquids such as a target solution containing a target substance and a solution containing surface-coated magnetic beads. The average particle size of the magnetic beads is in the range of 0.01-100 microns. The cavity 1 is cylindrical as a whole, but may also be in other shapes.

[0101] The magnet 25 is used to apply a magnetic field to a part of the cavity 21 to attract the magnetic beads to the inner wall of the cavity 21 .

[0102] There are three sample injectors, nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com