High thermal conductivity photovoltaic cell component and manufacturing method thereof

A technology for photovoltaic cells and manufacturing methods, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as affecting the photoelectric conversion efficiency of cells, decreasing cell efficiency, and heat dissipation performance affecting the conversion efficiency and service life of solar cells. , to achieve the effect of optimizing the hot pressing process, improving the utilization rate, improving the stability and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

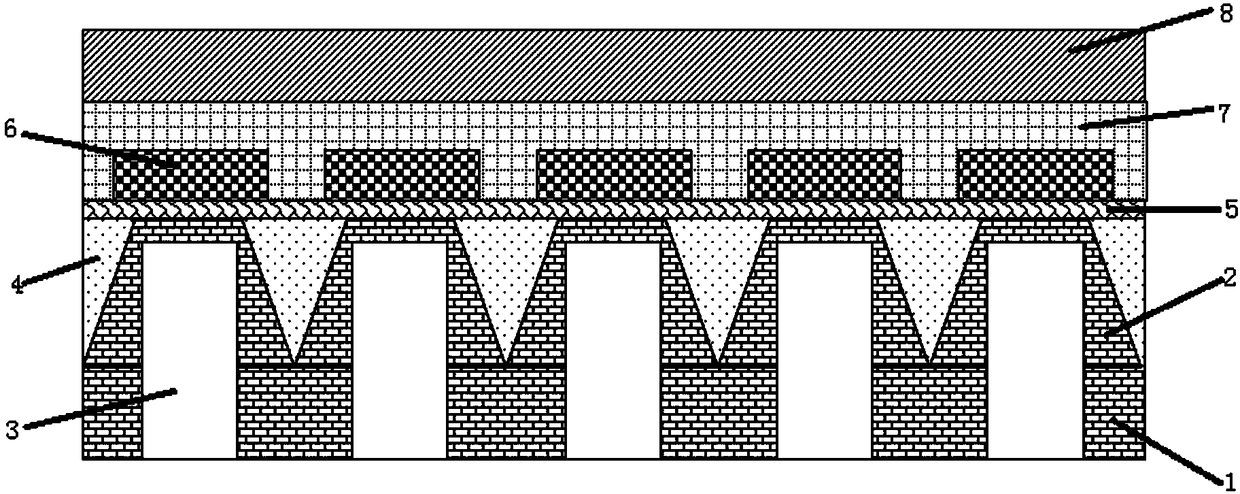

[0023] A method for manufacturing a high thermal conductivity photovoltaic cell assembly, comprising the following steps:

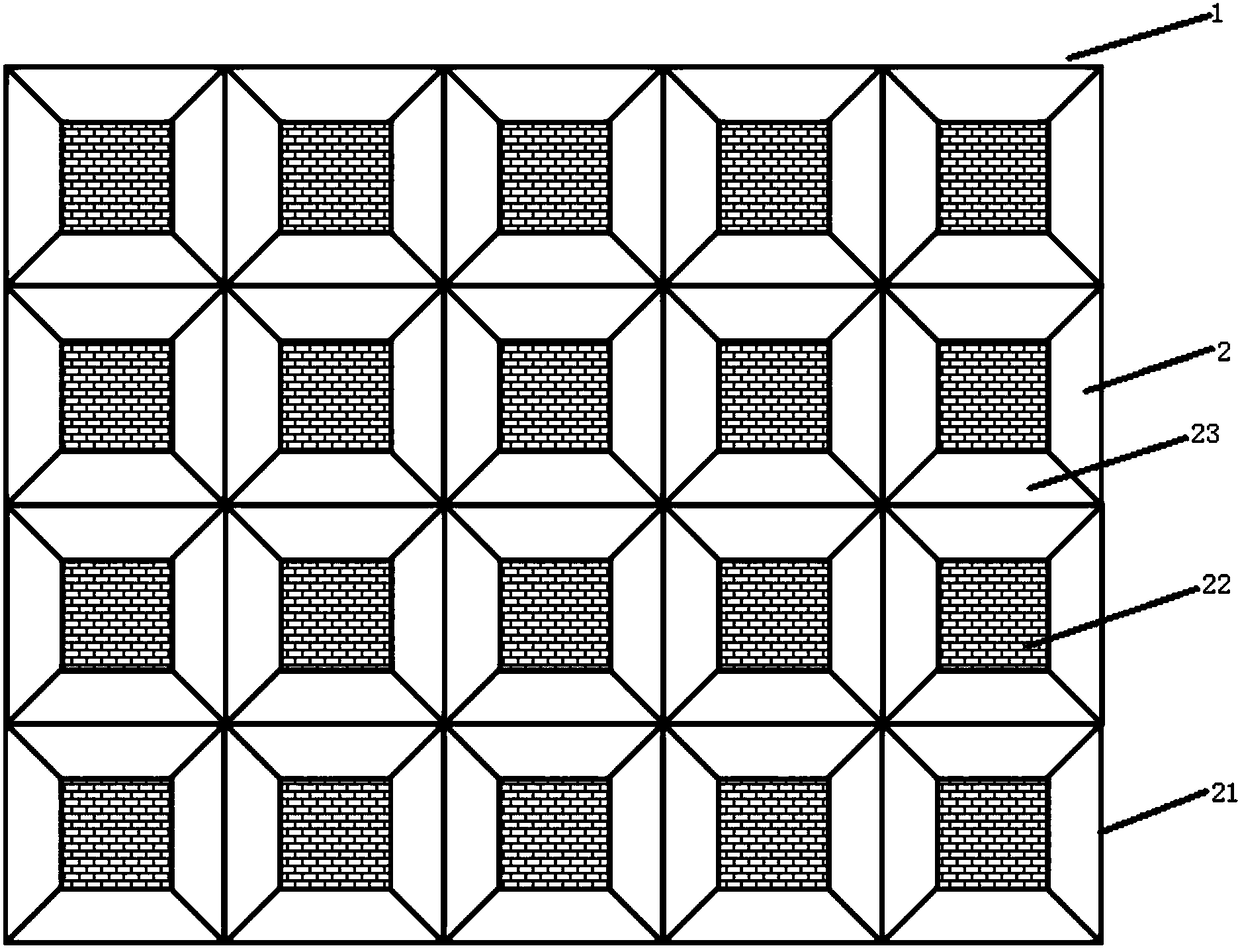

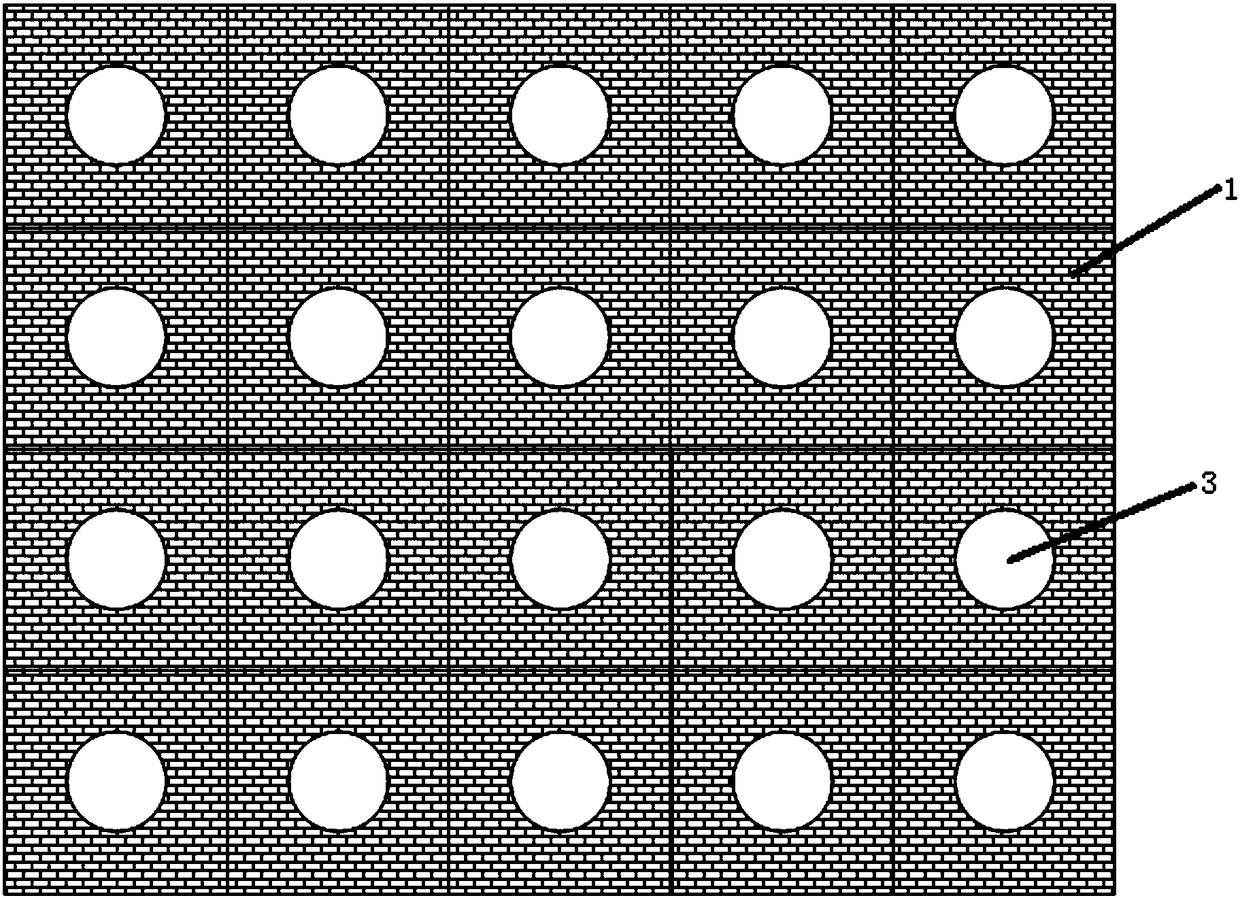

[0024]1) A plurality of protrusions are formed on the upper surface of the metal substrate, each of the protrusions includes a bottom surface and a top surface corresponding to the bottom surface, the bottom surface and the top surface are both square, the The side length of the bottom surface is greater than the side length of the top surface, and the protrusion also includes four inclined side surfaces, and the adjacent bottom surfaces between any adjacent protrusions share a side, and the side surfaces are polished processing, and then form a plurality of blind holes along the thickness direction of the metal substrate on the lower surface of the metal substrate, and form the protrusion by cutting, the side length of the top surface and the side length of the bottom surface The ratio is 0.8, the shape of the side surface is an isosceles trapezoid, the ...

Embodiment 2

[0029] A method for manufacturing a high thermal conductivity photovoltaic cell assembly, comprising the following steps:

[0030] 1) A plurality of protrusions are formed on the upper surface of the metal substrate, each of the protrusions includes a bottom surface and a top surface corresponding to the bottom surface, the bottom surface and the top surface are both square, the The side length of the bottom surface is greater than the side length of the top surface, and the protrusion also includes four inclined side surfaces, and the adjacent bottom surfaces between any adjacent protrusions share a side, and the side surfaces are polished processing, and then form a plurality of blind holes along the thickness direction of the metal substrate on the lower surface of the metal substrate, and form the protrusion by punching, the side length of the top surface is the same as the side length of the bottom surface The ratio is 0.5, the shape of the side surface is an isosceles tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com