Improved cartridge for feeding a stereolithography machine and stereolithography machine employing said cartridge

A lithography machine and three-dimensional technology, which is applied in microlithography exposure equipment, optomechanical equipment, accessories for processing main materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

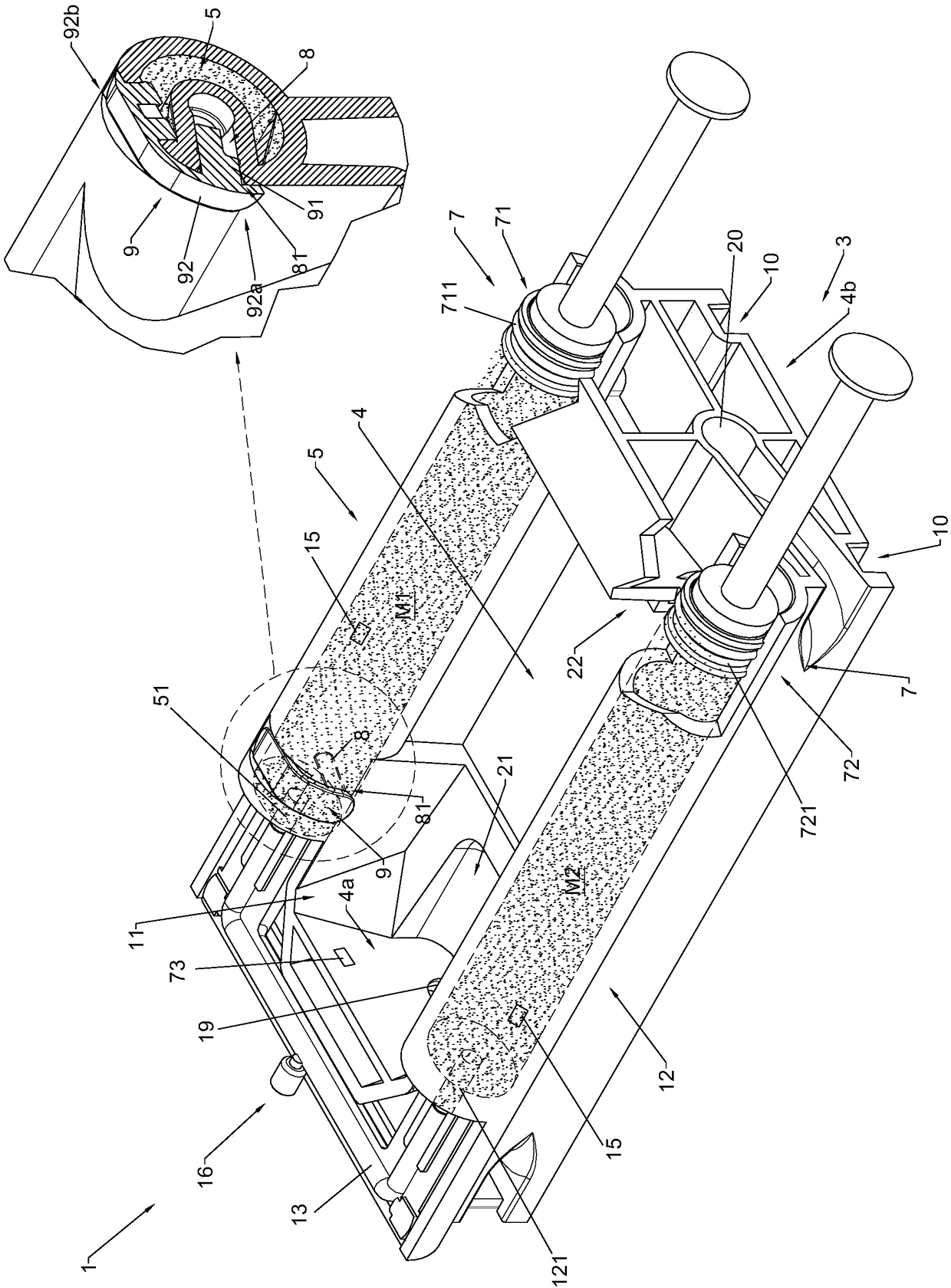

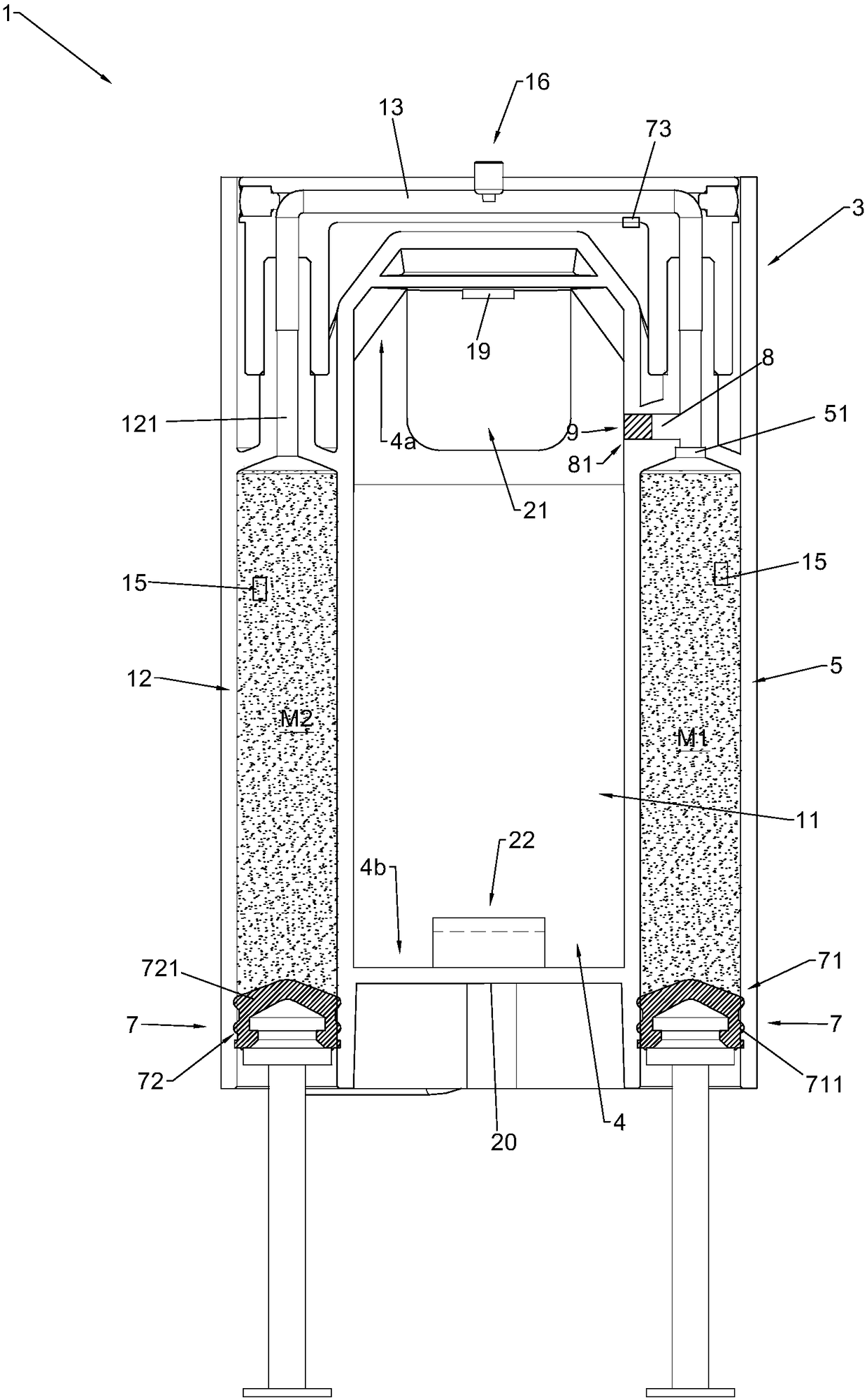

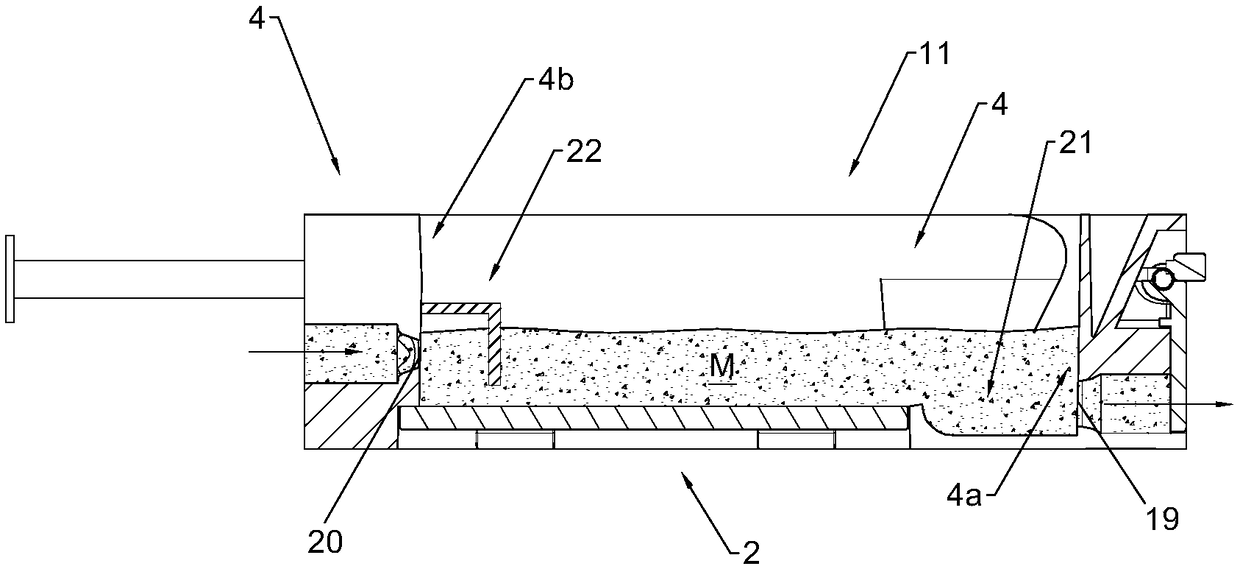

[0042] According to figure 1 and 2 In a first preferred embodiment, generally indicated by 1 , the cartridge of the invention for supplying a stereolithography machine comprises a support structure 3 associated with a container 4 .

[0043] However, it cannot be excluded that, in an alternative embodiment to said first preferred embodiment of the invention, said container 4 may not belong to the cartridge 1 of the invention, but may be inserted independently in the stereolithography machine 200 and a separate element associated with the same cartridge 1 in the operative configuration.

[0044] Cassette 1 also comprises a first reservoir 5 associated with support structure 3, adapted to contain a first liquid or pasty material M1 adapted to be obtained by exposure to a predetermined Radiation R and freeze. The first reservoir 5 communicates with the container 4 through a first conduit 8 facing the container 4 through a delivery port 81 .

[0045] Obviously, according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com