Bag molding method of composite material component

A composite material component and molding method technology, which is applied in the field of bag press forming composite materials, can solve the problems of forming wrinkles on the surface of the blank, bridging holes, scrapping composite material components, and breaking vacuum bags, etc., and achieves good deformability, Not easy to wrinkle, good fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

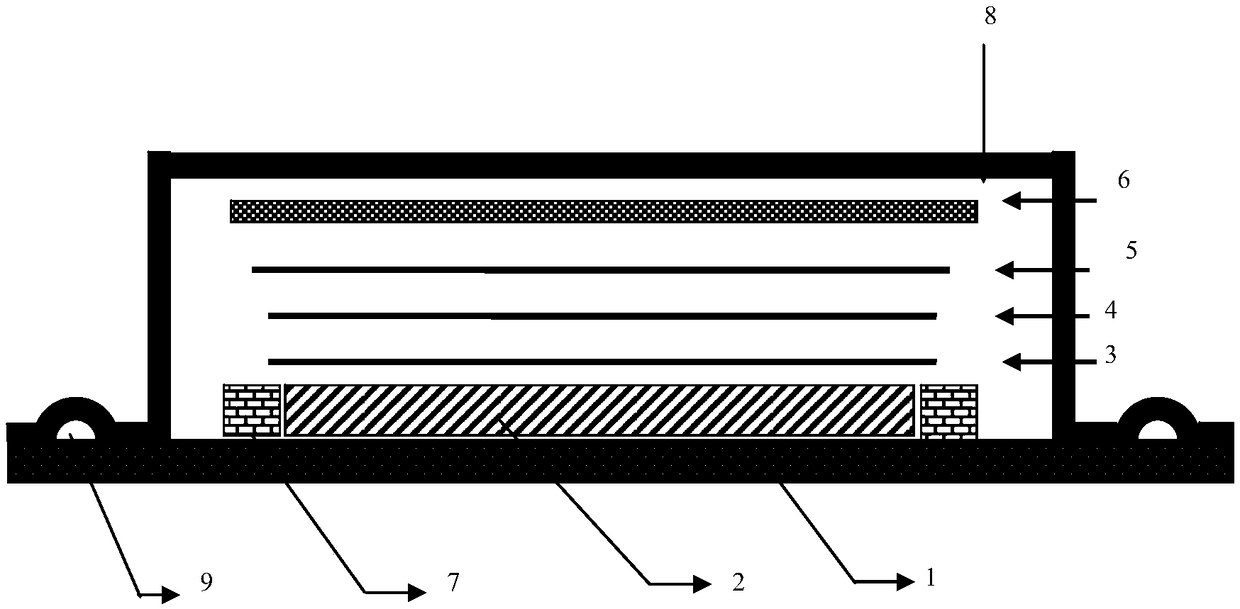

[0013] See figure 1 , a bag press forming method of a composite member of the present invention, comprising the following steps:

[0014] When the curing temperature is 220°C±5°C, choose heat-resistant plastic fabric R85PA66;

[0015] Lay composite material blank 2 on the surface of tooling 1 according to the specified angle, place a circle of vulcanized rubber retaining strip 7 around the blank 2; spread a layer of temperature-resistant plastic fabric 3 on the composite material blank; heat-resistant plastic fabric The surface is covered with a porous isolation film 4; a layer of non-porous isolation film 5 is tiled on the porous isolation film 4; a breathable cloth 6 is placed around the blank 2; a vacuum bag 8 is sealed with a sealing strip 9, vacuumized, and placed The curing and molding are completed in an oven or autoclave according to the specified curing process parameters.

[0016] The temperature-resistant plastic fabric 3 can also replace the release cloth, the po...

Embodiment 2

[0020] A bag press forming method for composite material components. When the curing temperature is 120 ° C ± 5 ° C, the temperature-resistant plastic fabric Bleeder lease B or KZ85PA is selected; the composite material blank 2 is laid on the surface of the tooling 1 according to the specified angle, and the blank 2 Place a circle of vulcanized rubber retaining strips 7 around the periphery; spread a layer of temperature-resistant plastic fabric 3 on the composite material blank; spread a porous isolation film 4 on the surface of the temperature-resistant plastic fabric; Layer non-porous isolation film 5; place air-permeable cloth 6 around the blank 2; seal the vacuum bag 8 with a sealing strip 9, vacuumize it, put it into an oven or autoclave according to the specified curing process parameters to complete the curing and molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com