Hydraulic winching

A winching and hydraulic technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc., can solve the problems of hidden safety hazards in line construction, few speed gears, large volume, etc., and achieve traction speed and Wide traction range, avoid equipment damage, high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

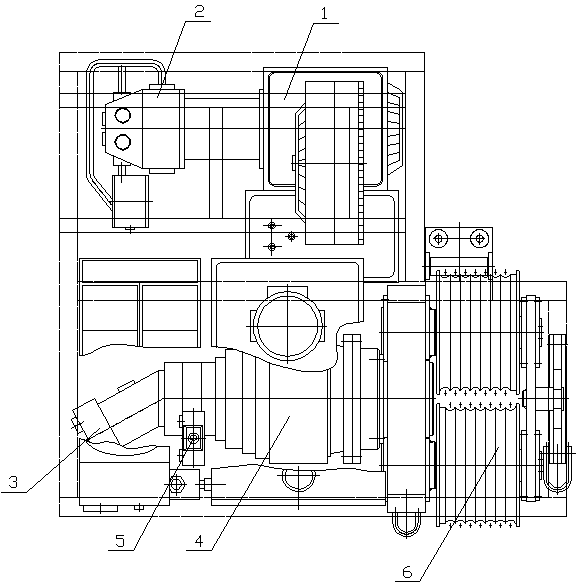

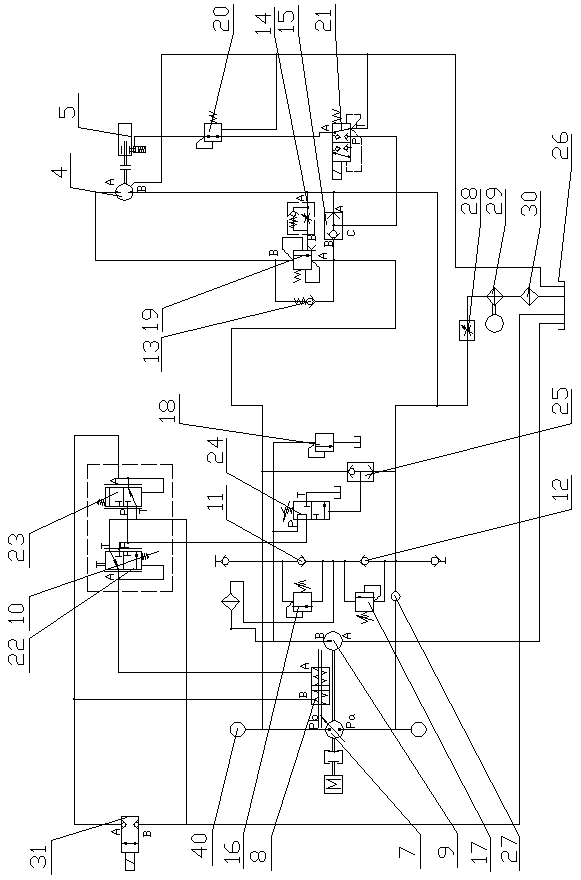

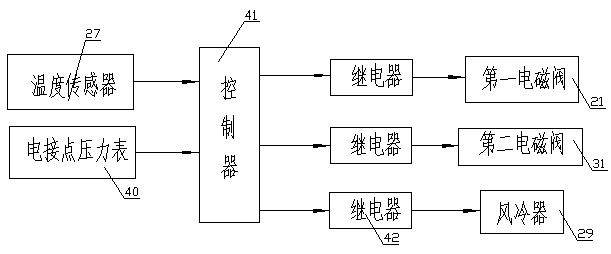

[0023] Such as figure 1 , 2 As shown, the present invention includes a gasoline engine 1, a hydraulic pump 2, a hydraulic motor 3, a speed reducer 4, a hydraulic brake 5, a winch mill cylinder 6 and a hydraulic system for controlling the hydraulic pump 2, the hydraulic motor 3, and the hydraulic brake 5. The gasoline engine 1 The power transmission end of the hydraulic pump 2 is connected, the output end of the hydraulic motor 3 is connected to the grinding cylinder 6 through the reducer 4, the hydraulic brake 5 is connected to the output end of the hydraulic motor 3, and the grinding cylinder 6 belongs to the prior art, which is divided into single twisting The specific structure of the grinding cylinder and the twisted grinding cylinder will not be repeated here.

[0024] The hydraulic pump 2 is a closed variable displacement plunger pump, including a main pump 7, a variable control cylinder 8 and an auxiliary pump 9, and the hydraulic brake 5 is a normally closed hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com