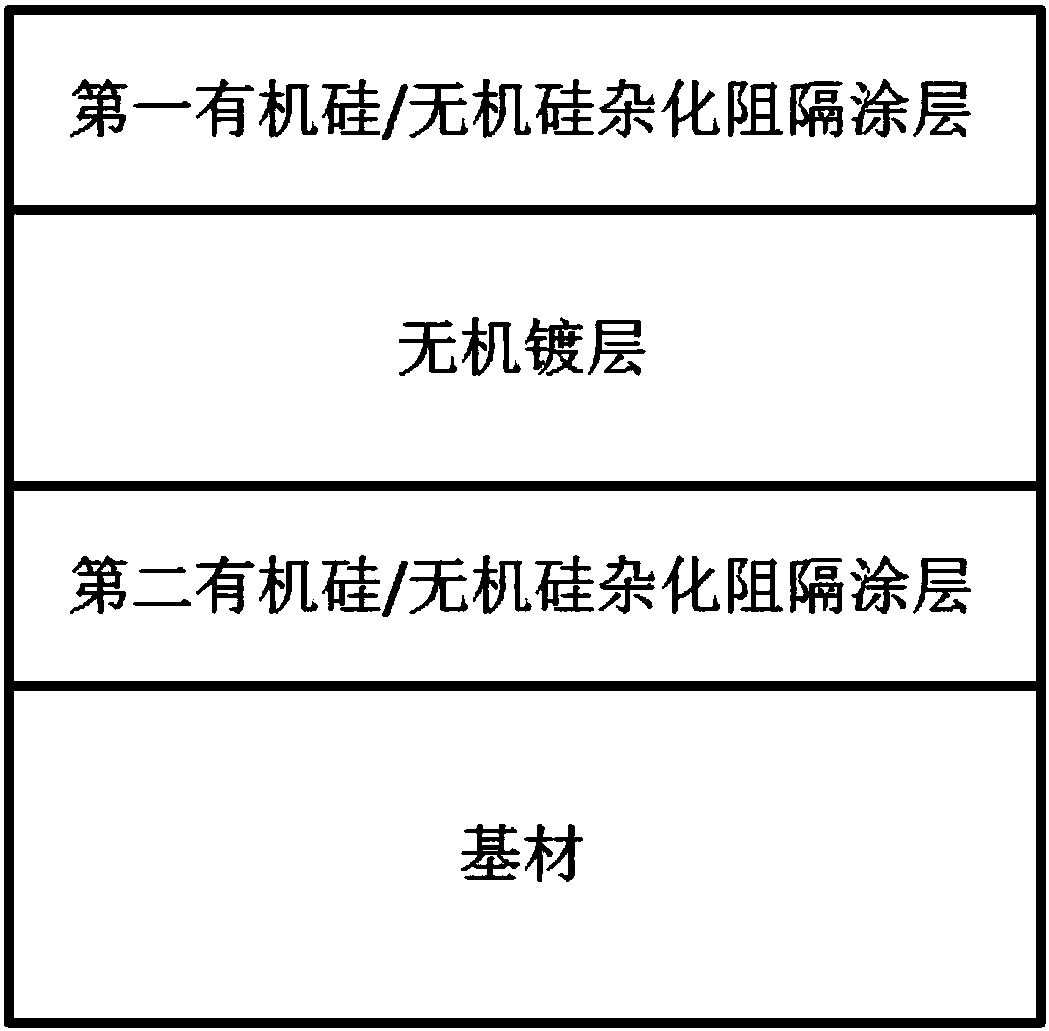

Organosilicone/inorganic silicon hybridization blocking coating composition and preparation method and application thereof

A barrier coating and silicone technology, applied in the field of functional polymers, can solve the problems of reduced water and oxygen barrier performance, process complexity, increased production costs, and insufficient interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

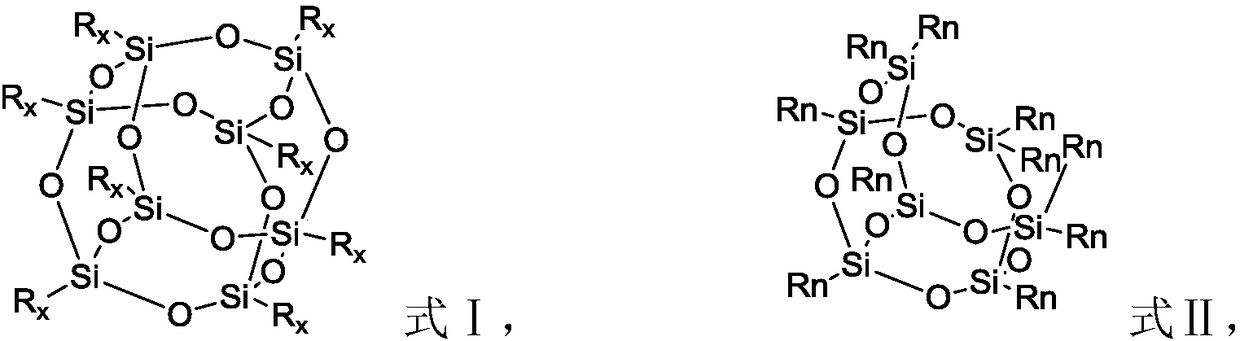

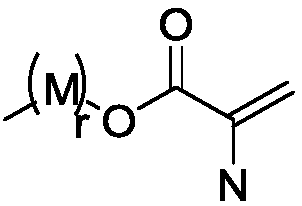

Method used

Image

Examples

Embodiment 1

[0084] An organosilicon / inorganic silicon hybrid barrier coating composition, consisting of the following components calculated in parts by weight:

[0085]

[0086] The preparation method of the described organosilicon / inorganic silicon hybrid barrier coating composition comprises the following steps:

[0087] (1) Put polyfunctional cage polysilsesquioxane, silicone resin, silicone-modified (meth)acrylic resin, photoinitiator, and additives in a planetary vacuum mixer, at a temperature of 40°C-50°C Under the conditions, stirring is carried out to obtain a mixture;

[0088] (2) Filter the mixture obtained in step (1) into a syringe with a 1600-mesh nylon filter cloth, then place the syringe in an oven, and heat and defoam at 50°C for 4 hours to obtain the silicone / Inorganic silicon hybrid barrier coating composition, the organosilicon / inorganic silicon hybrid barrier coating composition is a UV curable barrier coating glue.

Embodiment 2

[0090] An organosilicon / inorganic silicon hybrid barrier coating composition, the composition and preparation method of which are basically the same as in Example 1, except that the polyfunctional cage polysilsesquioxane used in Example 2 is B.

Embodiment 3

[0092] An organosilicon / inorganic silicon hybrid barrier coating composition, the composition and preparation method of which are basically the same as in Example 1, except that the polyfunctional cage polysilsesquioxane used in Example 3 is C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com