High-barrier-performance transparent and flexible display material and preparation method thereof

A flexible display, high barrier technology, applied in the field of flexible materials, can solve the problems of insufficient flexibility, the water and oxygen barrier layer is not resistant to bending, and cannot achieve long-term water and oxygen barrier properties, and achieves high water and oxygen barrier properties. The effect of excellent comprehensive performance and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A preparation method of a high-barrier transparent flexible display substrate material, comprising the following steps:

[0053] a) heating and reacting the cationic two-dimensional layered material with an organic intercalating agent in a solvent to obtain a layered material modified by organic intercalation;

[0054] b) exfoliating the organic intercalation-modified layered material in a solvent to obtain a nanosheet dispersion;

[0055] c) mixing the nanosheet dispersion with the polymerized monomer of polyimide and performing in-situ polymerization to obtain a polyamic acid slurry;

[0056] d) heat-treating the polyamic acid slurry to obtain a flexible display substrate material;

[0057] The cationic two-dimensional layered material is aluminosilicate layered material;

[0058] The organic intercalating agent is selected from one or more of organic amine salts, quaternary ammonium salts and quaternary phosphonium salts.

[0059] In the preparation method provide...

Embodiment 1

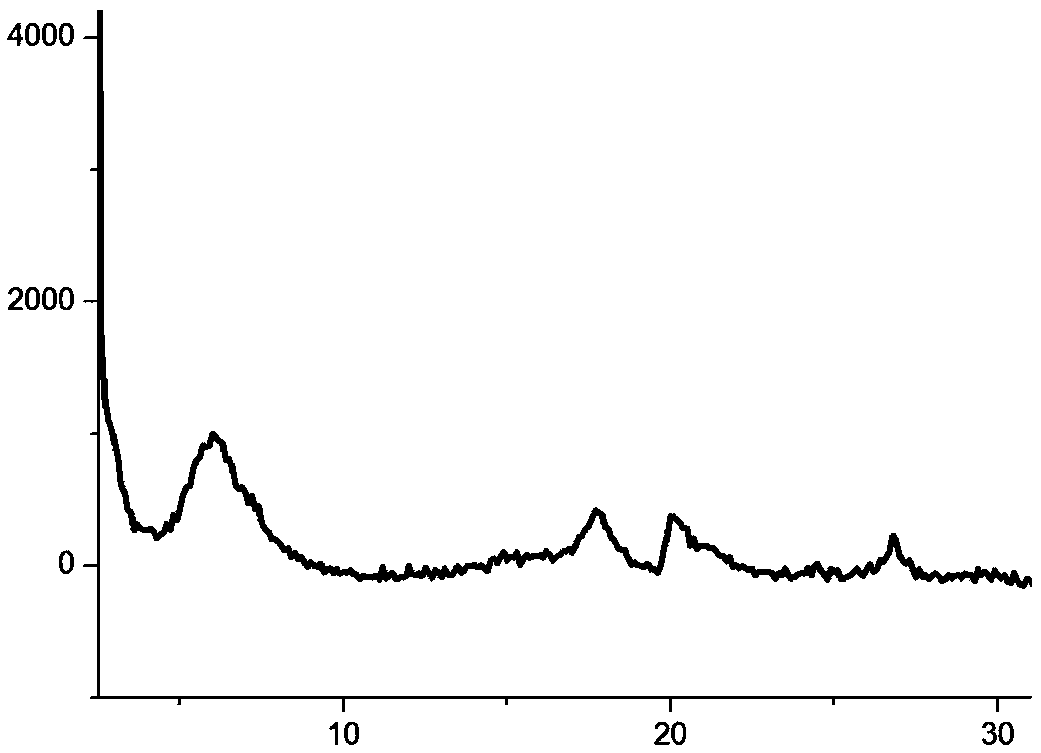

[0119] Add aniline hydrochloride (2.29g, 0.022mol) and sodium montmorillonite (10.0g, 0.01mol) into ethanol (100mL), heat to 70°C, and react for 12h. After that, the solid matter was filtered out and dried to obtain aniline intercalation modified montmorillonite with a yield of 95%. Gained sample is carried out wide-angle X-ray diffraction test, the result is as follows figure 1 as shown, figure 1 It is the X-ray diffraction pattern of aniline intercalation modified montmorillonite in Example 1. It can be seen that there is an obvious characteristic peak at 2θ=6.5°, and the interlayer distance is enlarged to 1.38nm calculated by combining with the Bragg equation.

[0120] The obtained montmorillonite modified by aniline intercalation (0.11 g) was added into N,N-dimethylacetamide (20.0 g), and ultrasonicated at room temperature for 3 h to obtain a dispersion liquid of exfoliated and dispersed montmorillonite nanosheets. Add 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (3.2...

Embodiment 2

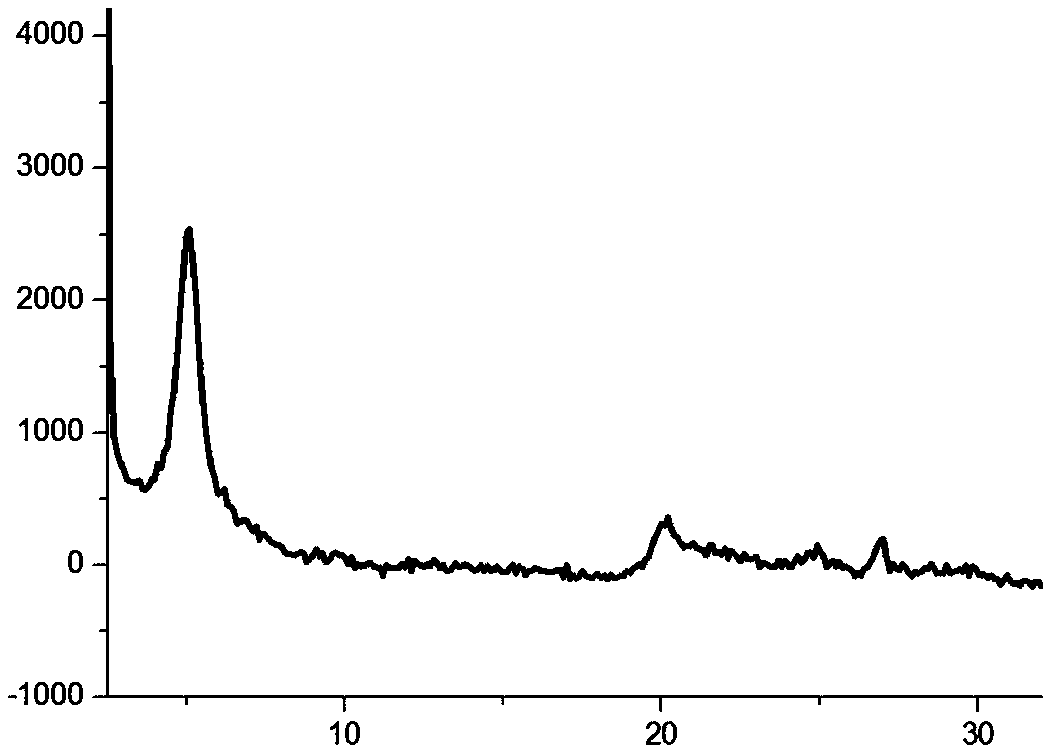

[0122] Add 4-hydroxyaniline hydrochloride (3.18g, 0.023mol) and sodium montmorillonite (10.0g, 0.01mol) into dioxane (100mL), heat to 100°C, and react for 12h. After that, the solid matter was filtered out and dried to obtain 4-hydroxyaniline intercalated modified montmorillonite with a yield of 97%. Gained sample is carried out wide-angle X-ray diffraction test, the result is as follows figure 2 as shown, figure 2 It is the X-ray diffraction pattern of 4-hydroxyaniline intercalation modified montmorillonite in Example 2. It can be seen that there is an obvious characteristic peak at 2θ=5.1°, and the interlayer distance is enlarged to 1.73nm calculated by combining with the Bragg equation.

[0123] The resulting 4-hydroxyaniline intercalation-modified montmorillonite (0.08 g) was added to N,N-dimethylformamide (19.0 g), and ultrasonicated at room temperature for 2 h to obtain a dispersion of exfoliated and dispersed montmorillonite nanosheets. 1,4-Diaminocyclohexane (1.14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com