Bacteriostatic compounding agent applied to metal cutting fluid and preparation method and application thereof

A technology of metal cutting fluid and compounding agent, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of allergies, smelly employees, and bacteria that are easy to grow in the liquid, so as to solve the problem of reducing PH and odor, and improving antibacterial performance. , the effect of large alkali reserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

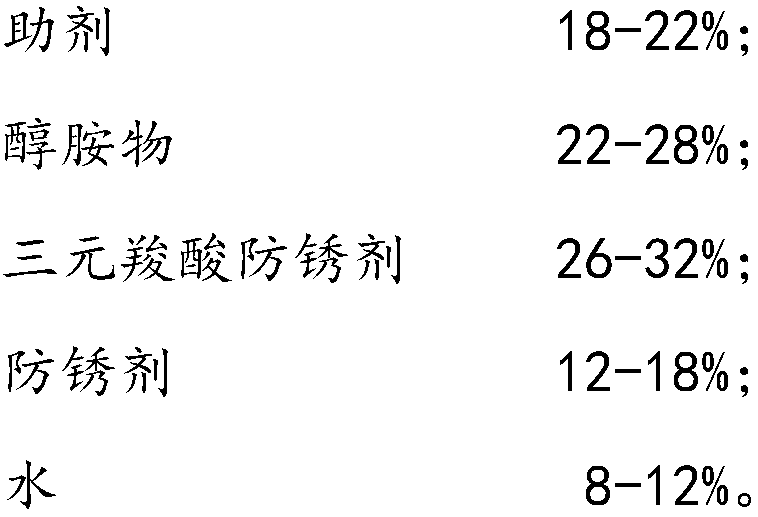

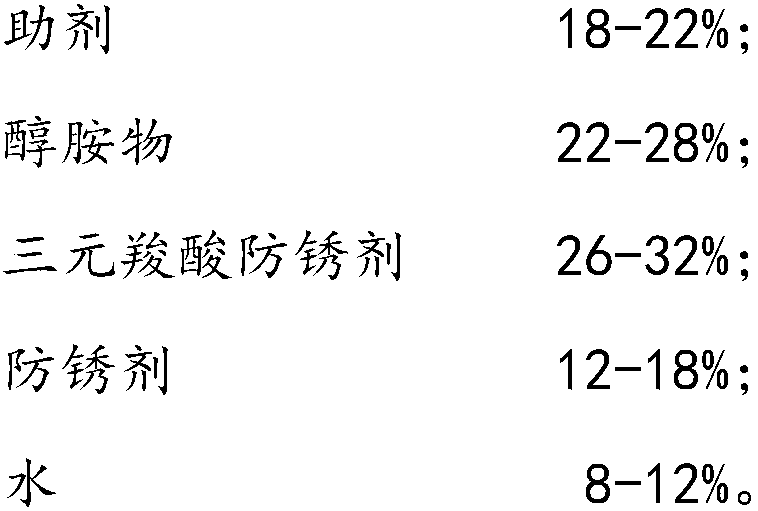

[0026] Add 20% of AMP-95 additive, 25% of Genamin CH 020 (J) alcohol amine, 29% of tribasic carboxylic acid antirust agent, 16% of DB-1 antirust agent and 10% of distilled water. Specifically, the following weight ratios can be used: 20g of MP-95 additive, 25g of Genamin CH020 (J) alcohol amine, 29g of tricarboxylic acid antirust agent, 16g of DB-1 antirust agent and 10g of distilled water.

[0027] The preparation process is as follows: In a beaker, add 10g of distilled water, 20g of AMP-95 and 25g of Genamin CH 020(J), stir evenly until transparent. Add 29g of tricarboxylic acid antirust agent and 16g of DB-1 and stir for 1 hour until it is uniform and transparent, and composite agent A is obtained.

[0028] In application, it is mainly used in emulsified semi-synthetic cutting fluid, the addition amount is 10-20%, the effect is the best, it has a large alkali reserve, excellent antibacterial performance and biological stability, good emulsification performance, etc.

[002...

Embodiment 2

[0031] Others are the same as Example 1, the difference is that the proportioning is different: add 18% of AMP-95 auxiliary agent, 22% of GenaminCH 020 (J) alcohol amine, 32% of tribasic carboxylic acid antirust agent, DB-1 antirust agent Rust agent 18% and distilled water 10%.

Embodiment 3

[0033] Others are the same as Example 1, except that the proportioning is different: add 22% of AMP-95 auxiliary agent, 28% of GenaminCH 020 (J) alcohol amine, 26% of tribasic carboxylic acid antirust agent, DB-1 antirust agent Rust agent 12% and distilled water 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com