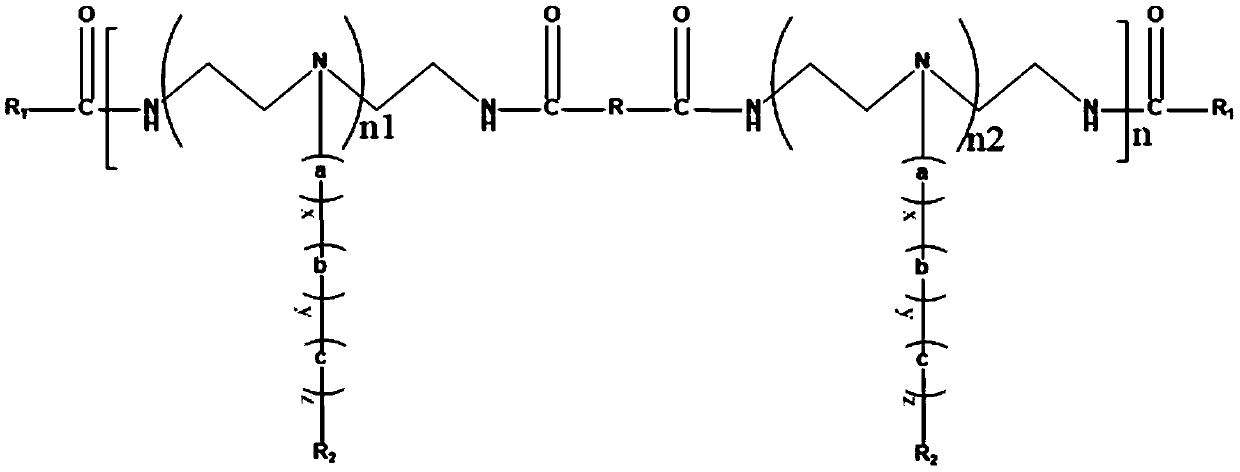

Viscoelastic auxiliary agent, and composition, preparation method and application thereof

A technology of bomb adjuvant and composition, applied in the field of pesticide adjuvant, can solve the problems of pollution of the environment, waste of NH3, complicated preparation process of polyetheramine, etc., and achieve the effects of good compatibility, reduction of by-products, and improvement of physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The embodiment of the present invention discloses a droplet viscoelastic water-based polymer additive and its composition. The preparation method specifically includes the following steps:

[0058] (1) Add 2.75g of methanesulfonic acid and 561g of dimer acid (HONGTAI) into the reaction kettle, and replace it with nitrogen for 3 times, raise the temperature to 140-160°C, add 156g of diethylenetriamine dropwise, and pass through Inject nitrogen for dehydration, while controlling the dropping temperature at 140-160°C, and the dropping time is 2.5-3h. After the dropping is completed, control the temperature at 160-165°C to carry out the aging reaction, and the aging time is 4-6h. When about 36g of water is collected, detect When the acid value is less than 2.5mgKOH / g, add 280g of oleic acid, control the temperature at 180-185°C, and dehydrate with nitrogen gas. The aging time is 5-7h. When about 18g of water is collected, the acid value is less than 1.8mgKOH / g , and finally...

Embodiment 2

[0065] The embodiment of the present invention discloses a droplet viscoelastic water-based polymer additive and its composition. The preparation method specifically includes the following steps:

[0066] (1) Add 3.1g p-toluenesulfonic acid, 561g dimer acid (UNIDYME TM14), and replace it with nitrogen for 3 times, increase the temperature to 140-160°C, add 347g of pentaethylenehexamine dropwise, and dehydrate with nitrogen, while controlling the dropping temperature to 180-190°C, and the dropping time is 2.5- 3h, the dropwise addition is completed, and the temperature is controlled at 180-190°C for aging reaction. The aging time is 4-6h. When about 36g of water is collected, the acid value is less than 1.8mgKOH / g, and 216g of oleic acid is added, and the temperature is controlled at 180-195°C. It is dehydrated with nitrogen gas, and the aging time is 5-7 hours. When about 18g of water is collected and the acid value is less than 1.2mgKOH / g, it is finally vacuumed at 80-85°C to...

Embodiment 3

[0073] The embodiment of the present invention discloses a droplet viscoelastic water-based polymer additive and its composition. The preparation method specifically includes the following steps:

[0074] (1) Add 7.5g p-toluenesulfonic acid, 561g dimer acid (UNIDYME TM 18), and replaced with nitrogen for 3 times, raised the temperature to 140-160°C, added 138g of diethylenetriamine dropwise, and dehydrated with nitrogen, while controlling the dropping temperature to 180-190°C, and the dropping time was 2.5- After 3 hours, the dropwise addition is completed, and the temperature is controlled at 180-190°C to carry out the aging reaction. The aging time is 4-6h. When about 35g of water is collected and the acid value is less than 4mgKOH / g, add 228g of coconut oleic acid and control the temperature at 180-195°C. It is dehydrated with nitrogen gas, and the aging time is 5-7h. When about 11g of water is collected and the acid value is less than 0.8mgKOH / g, it is finally vacuumed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com