A plant-mixed thermal regeneration method capable of realizing full regeneration of rap

A technology of thermal regeneration and heating method, applied in the field of thermal regeneration of plant mixing, can solve the problems of low RAP recycling and use, RAP cannot be reused, etc., and achieve the effect of ensuring the quality of gradation control and low heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

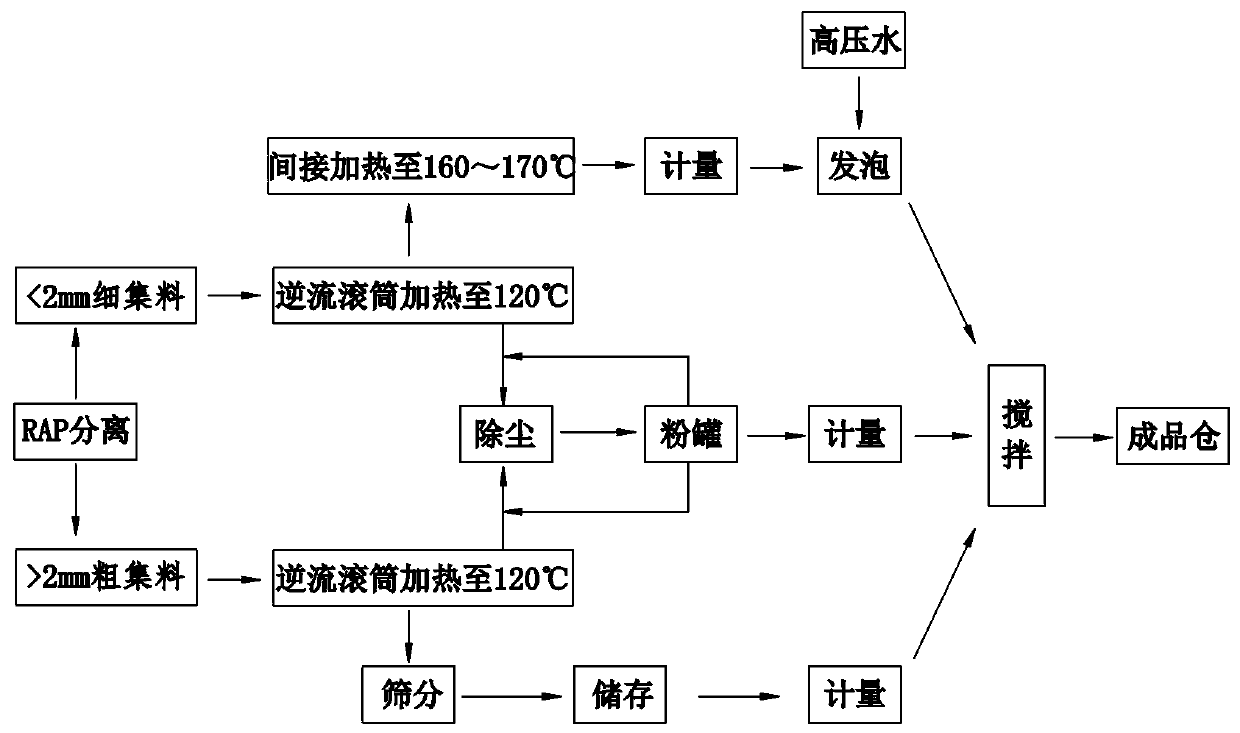

[0024] The present invention discloses a plant-mixed heat regeneration method that can realize full regeneration of RAP, referring to figure 1 , including the following steps:

[0025] (1) Crushing and screening the RAP, and classifying the RAP into fine aggregate with a particle size less than 2mm and coarse aggregate with a particle size larger than 2mm.

[0026] (2) Separately heat fine aggregate and coarse aggregate: use two-stage heating to heat fine aggregate to 160-170°C to make it melt into latex; heat coarse aggregate to 120°C.

[0027] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com