A kind of production method of oat whole grain extrusion product

A production method and grain technology, applied in the field of food processing, can solve the problems of difficult storage, difficult storage of products, high fat content, etc., and achieve the effects of controlling starch aging, good market prospects, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

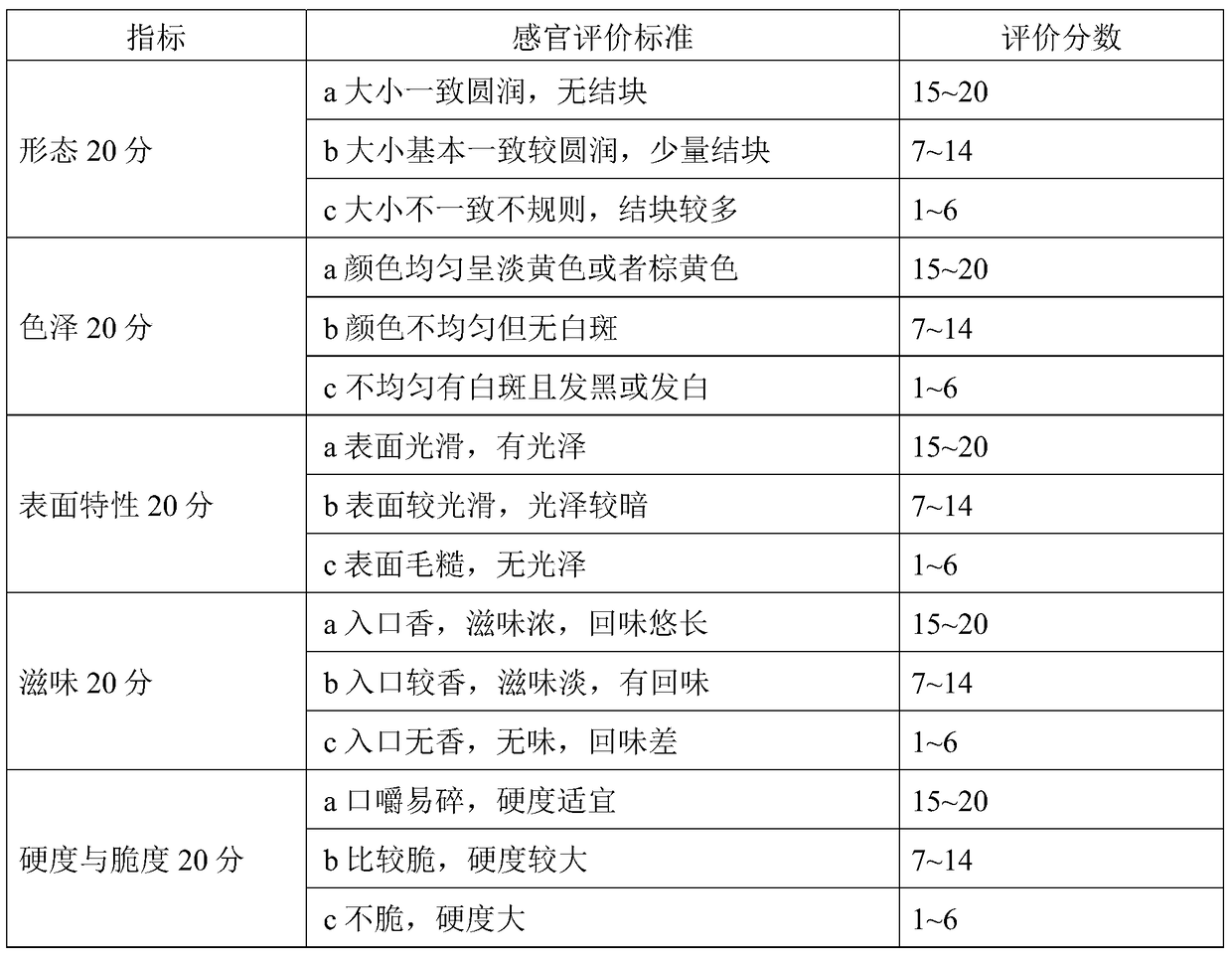

Examples

Embodiment 1

[0022] Taking the production of 50kg oat whole grain extruded products as an example, the method for producing oat whole grain extruded products consists of the following steps:

[0023] (1) Pretreatment of raw materials

[0024] Dry the selected whole grains of oats with the wind, blow off the bran with the blower, and wash them with water. The oats with shells can float on the water, then sieve off the oats with shells on the upper layer, drain the water, weigh 30kg, add water to all All the oats are submerged in water, soaked at room temperature for 2 hours, boiled in boiling water for 10 minutes to soften, drain the water, add 20kg of starch to it, and stir evenly.

[0025] (2) Extrusion treatment

[0026] Set the initial rotation speed of the screw of the screw extruder to 100r / min, the constant rotation speed to 280r / min, the temperature to 150°C, and the solid feeding speed to 12kg / min; Turn on the machine, drain water to make the passage of the extruder smooth, turn ...

Embodiment 2

[0030] Taking the production of 50kg oat whole grain extruded products as an example, the method for producing oat whole grain extruded products consists of the following steps:

[0031] (1) Pretreatment of raw materials

[0032] Weigh 45kg of selected shelled whole oat grains, add water until all the oats are submerged in water, soak at room temperature for 2 hours, cook in boiling water for 8 minutes to soften, drain the water, add 5kg of starch to it, and stir evenly.

[0033] (2) Extrusion treatment

[0034] The set temperature is 140°C, and the solid feeding rate is 10kg / min; when the temperature of each zone of the screw extruder reaches the set value, start the machine, and add the pretreated whole oat grains into the screw extruder. It should not be too high, and keep constant after rising from 100r / min to 250r / min. After the discharge is stable, the cutter is turned on, and the primary product of oat whole grain extrusion is obtained.

[0035] (3) Modeling and dryin...

Embodiment 3

[0038] Taking the production of 50kg oat whole grain extruded products as an example, the method for producing oat whole grain extruded products consists of the following steps:

[0039] (1) Pretreatment of raw materials

[0040] Weigh 35kg of selected shelled whole oat grains, add water until all the oats are submerged in water, soak at room temperature for 2 hours, cook in boiling water for 15 minutes to soften, drain the water, add 15kg of starch to it, and stir well.

[0041] (2) Extrusion treatment

[0042] The set temperature is 160°C, and the solid feeding rate is 15kg / min; after the temperature of each zone of the screw extruder reaches the set value, start the machine, and add the pretreated whole oat grains into the screw extruder. It should not be too high, and keep constant after rising from 100r / min to 300r / min. After the discharge is stable, the cutter is turned on, and the primary product of oat whole grain extrusion is obtained.

[0043] (3) Modeling and dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com