Rotary drilling tooth of rotary drilling machine

A rotary digging machine and root technology, applied in the field of rotary digging teeth, can solve problems such as shortened service life of rotary digging teeth, stuck rotary digging teeth, failure to form spin, etc., and achieve the effect of improving the holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

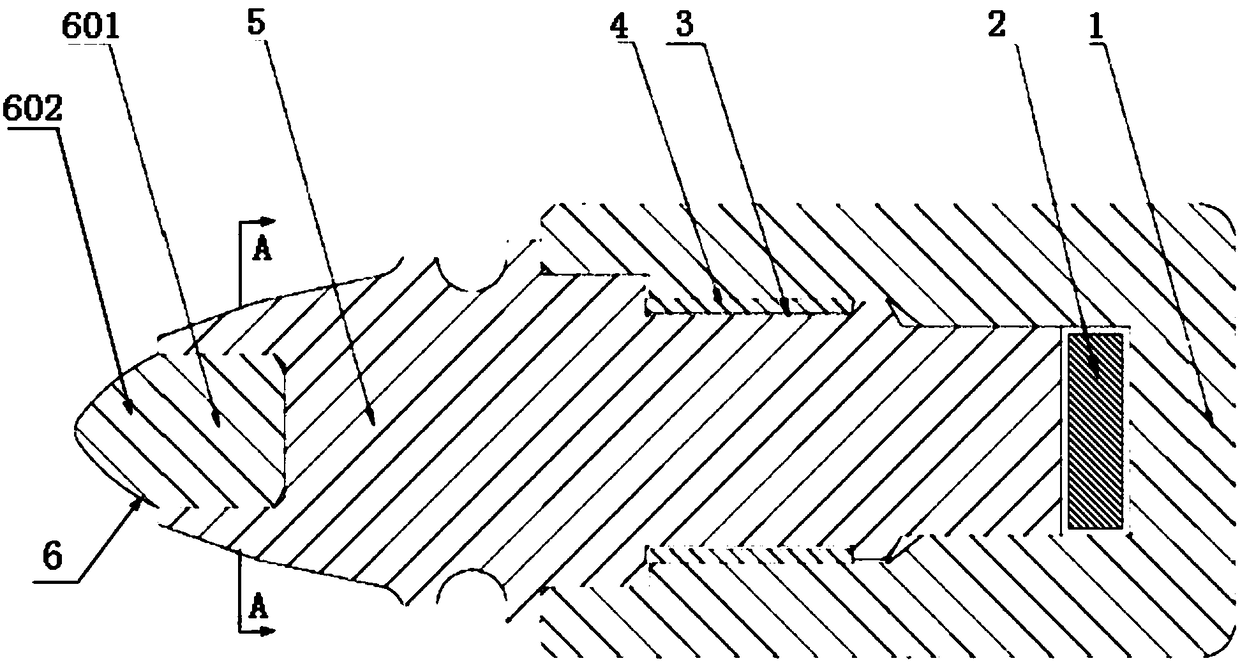

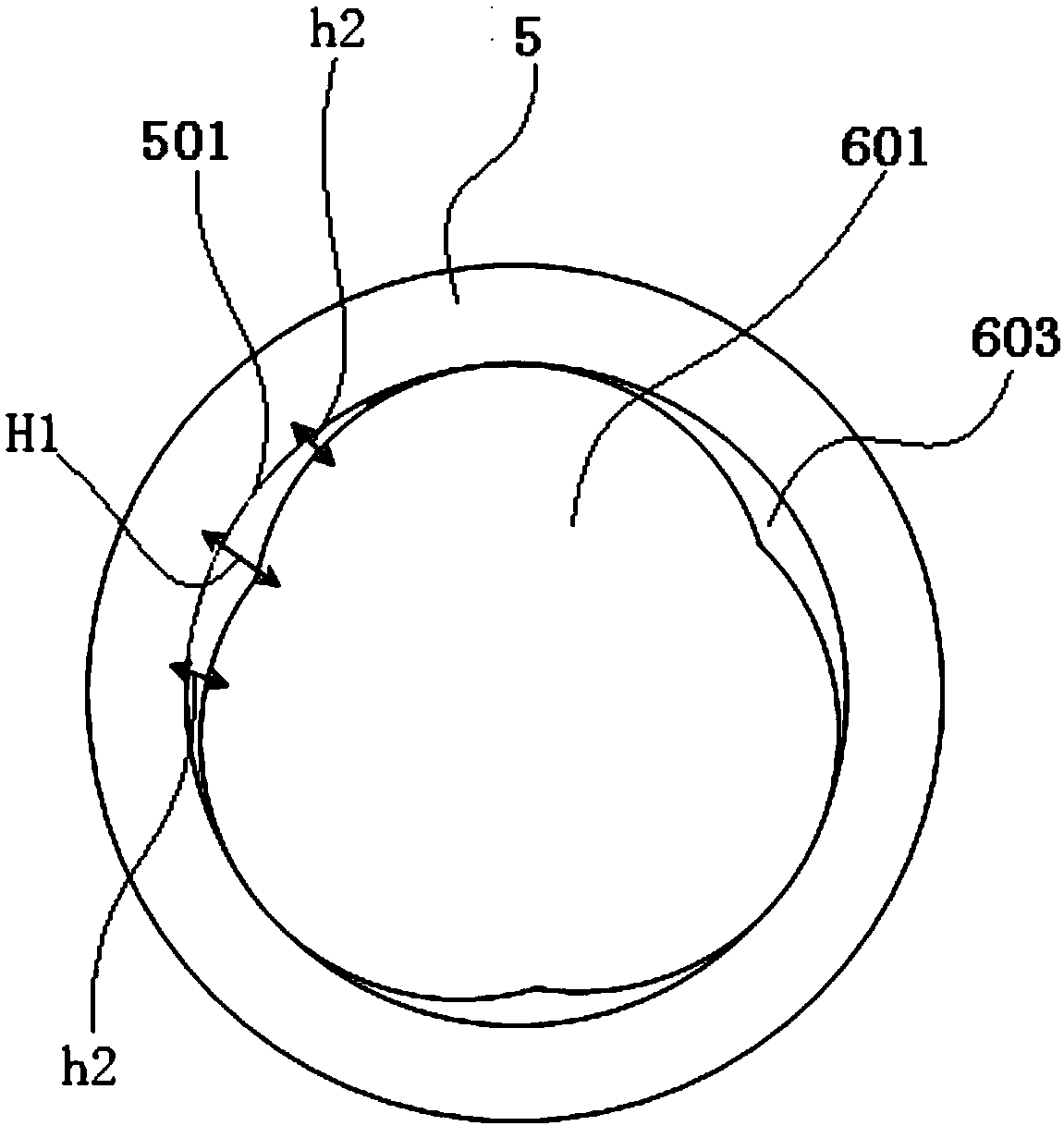

[0017] Embodiment 1: referring to accompanying drawing, reflect a kind of concrete structure of the present invention, the head device cemented carbide rod 6 of the rotary digging tooth 5 of described rotary digging machine, the cylindrical root of rotary digging tooth 5 is equipped with sleeve card The spring 4 and the sleeve spring 4 are pressed into the slot 3 of the inner cavity of the rotary digging tooth holder 1, thereby restricting the axial relative movement of the rotary digging tooth 5 and the rotary digging tooth holder 1, and realizing the rotation of the rotary digging tooth 5 and the rotary digging tooth holder 1. The rotatable sleeve connection between the tooth holders 1 . A gasket 2 is installed between the end face of the cylindrical root of the rotary digging tooth 5 and the end face of the rotary digging tooth seat 1 inner cavity. During the work of the rotary digging gear, as the bucket drill bit goes deeper into the excavation surface, the mud and rock m...

Embodiment 2

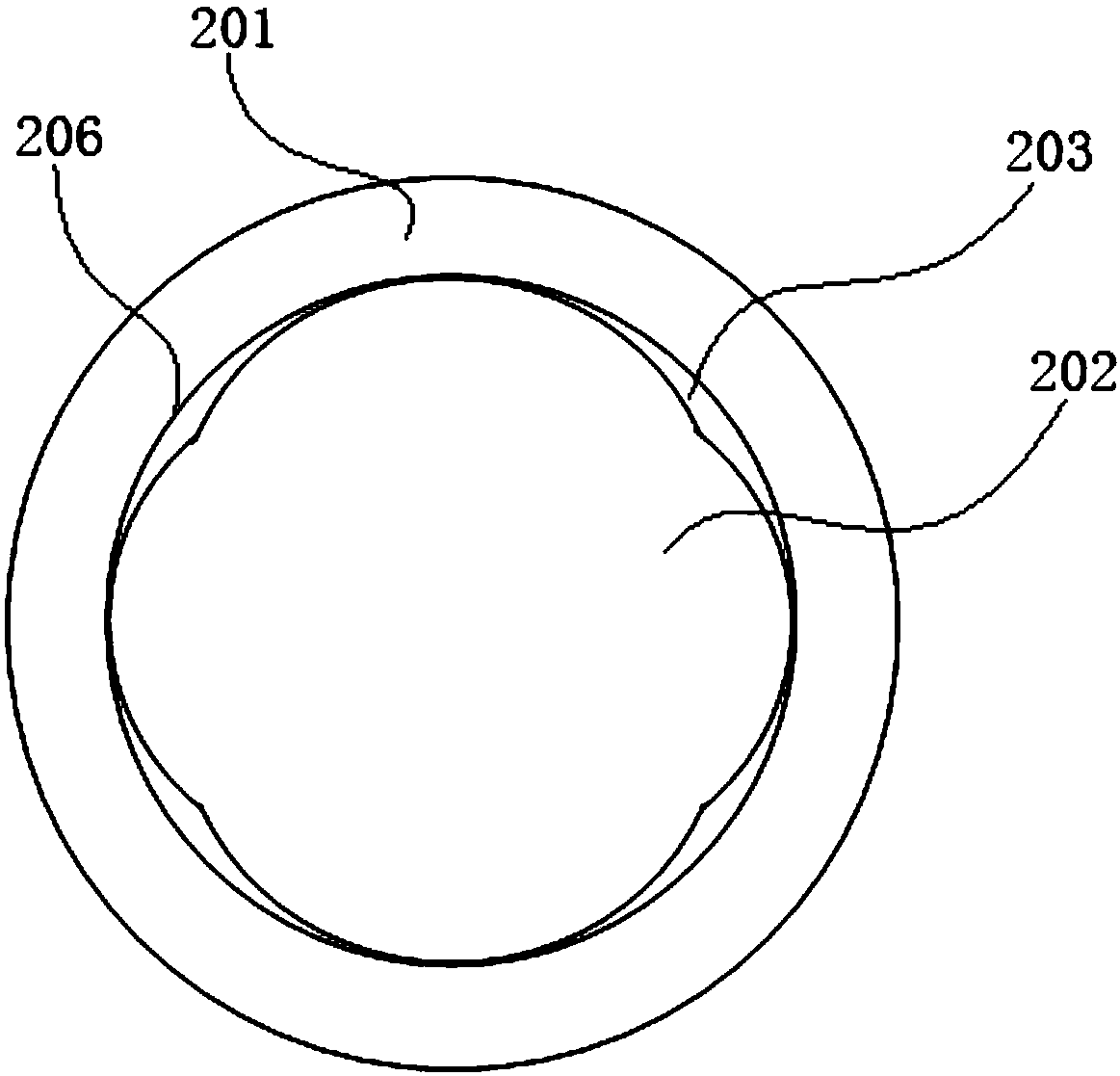

[0020] Example 2: see image 3 The root 202 of the cemented carbide rod is inserted into the mounting hole 206 of the rotary digging tooth 201. The difference from Embodiment 1 is that the number of grooves 203 evenly distributed in the circumferential direction on the side of the root 202 is four.

Embodiment 3

[0021] Embodiment 3: see Figure 4 The root 302 of the cemented carbide rod is inserted into the mounting hole 306 of the rotary digging tooth 301. The difference from Embodiment 1 is that the number of grooves 303 evenly distributed in the circumferential direction of the root 302 is four. The groove 303 is an arc groove, and the cross section of the root 302 constitutes as Figure 4 The arc notch shown is circular, not quincunx.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com