Gas analyzer with synchronization of differential pressure flow measurement and extraction

A gas analysis and flow measurement technology, which is applied to measurement devices, sampling devices, and fluid flow detection by measuring differential pressure. , the effect of reducing equipment cost and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

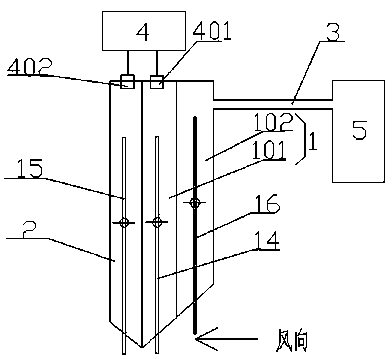

[0033] This embodiment provides a gas analysis device with simultaneous flow measurement and extraction, such as figure 1 As shown, the square total pressure measuring tube 1 and static pressure measuring tube 2, the pressure measuring part 4 (preferably Rosemount differential pressure transmitter), the gas analysis part 5 (preferably extracting type optical gas analyzer), a gas collection tube 3 with a diameter of 1 cm, a server-based computing processor (not shown in the figure), a first cleaning part 12 (preferably using a cleaning rod with irregular motion) and a second The second dust cleaning part 13 (preferably using a dust cleaning rod with irregular movement), the total pressure measurement tube 1 and the static pressure measurement tube 2 are welded and fixed together back to back, the total pressure measurement tube 1 is placed against the wind, and the static pressure measurement tube 2 is not Placed against the wind, both ends are closed ends, the pressure measuri...

Embodiment approach 2

[0038] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, since the first measurement probe 401 of the pressure measurement component 4 is located in the full pressure measurement tube 1, the gas collection tube of the gas analysis component 5 3 is also communicated with the total pressure measuring tube 1. When the first measuring probe 401 measures the gas pressure in the total pressure measuring tube 1, the gas flow rate and The pressure will cause inaccuracy of the pressure in the total pressure measuring tube 1 measured by the first measuring probe 401 ; however, in this embodiment, the above defects can be effectively avoided.

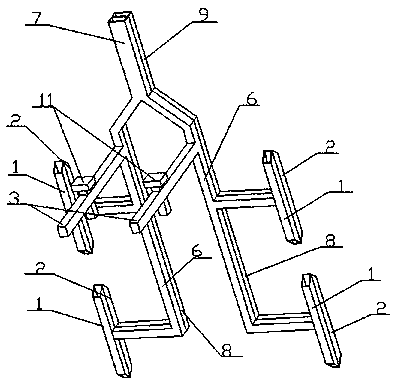

[0039] Specifically, as figure 2 , in the gas analysis device with differential pressure flow measurement and extraction synchronous in the present embodiment, the valve part 11 connected with the arithmetic processor signal is also set on the gas collection pipe 3, when the pressure measuring...

Embodiment approach 3

[0043] This embodiment is a further improvement of Embodiment 2. The main improvement is that, in Embodiment 2, there is only one total pressure measuring tube 1 and one static pressure measuring tube 2 in the measurement space. The flow rate, air pressure, and composition of different positions in the space may be different and change frequently. If the measuring tube is only installed at one measuring point in the measuring space, the measurement and analysis results of the pressure measuring part 4 and the gas analyzing part 5 will inevitably be different. Accurate; and this implementation mode can avoid above-mentioned defect, specifically:

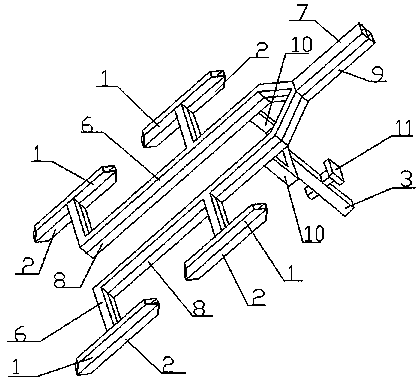

[0044] Such as image 3 , in this embodiment, four total pressure measurement tubes 1 and four static pressure measurement tubes 2 are arranged in different positions in the same measurement space in all directions; two total pressure measurement tubes 1 are connected to the total pressure by a total pressure measurement branch pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com