A piston and pneumatic dual-purpose 3D printing biomaterial extrusion test device

A 3D printing and biomaterial technology, which is applied in the field of piston and pneumatic dual-purpose 3D printing biomaterial extrusion test devices to achieve high integration, liberate experimenters, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

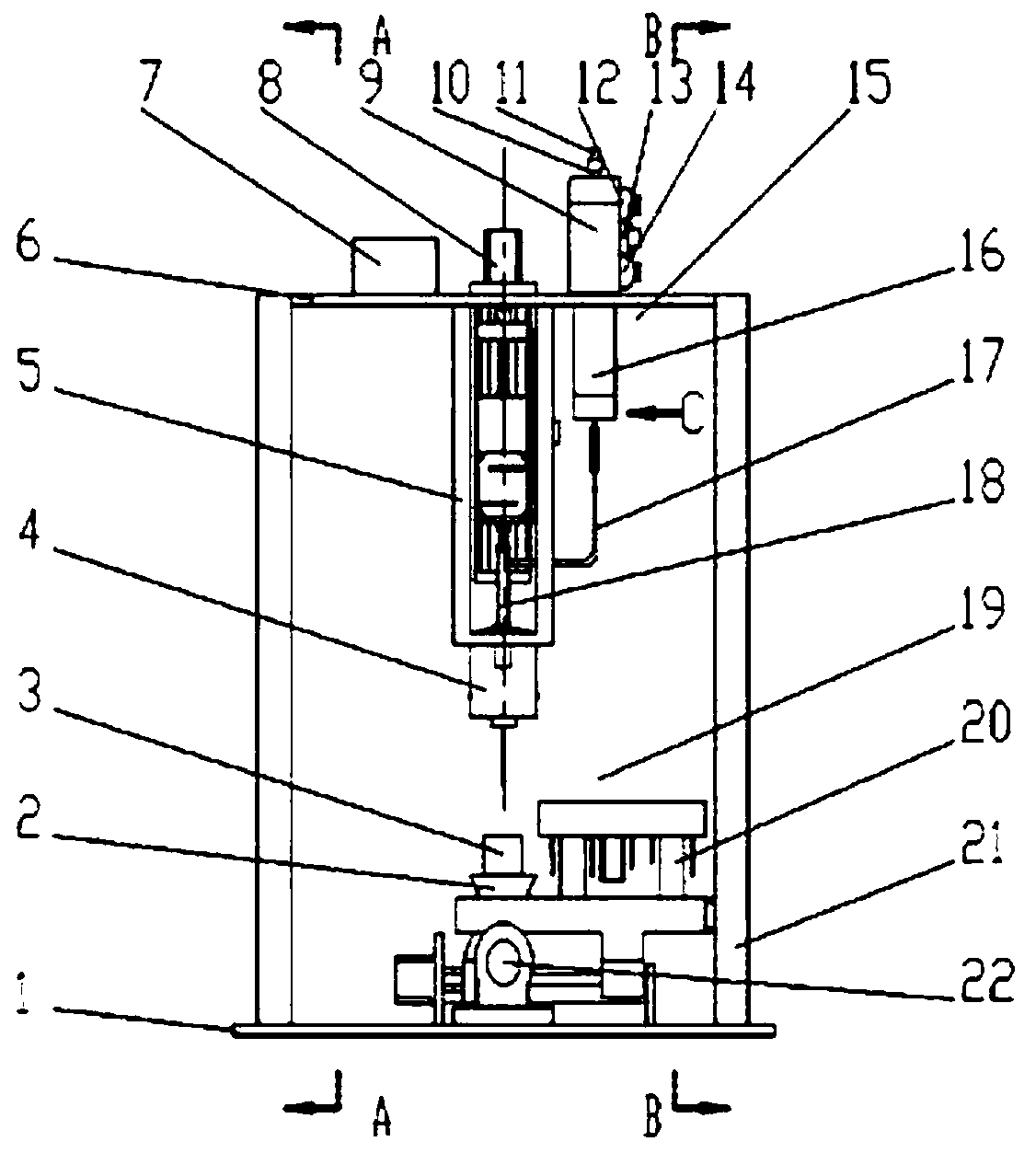

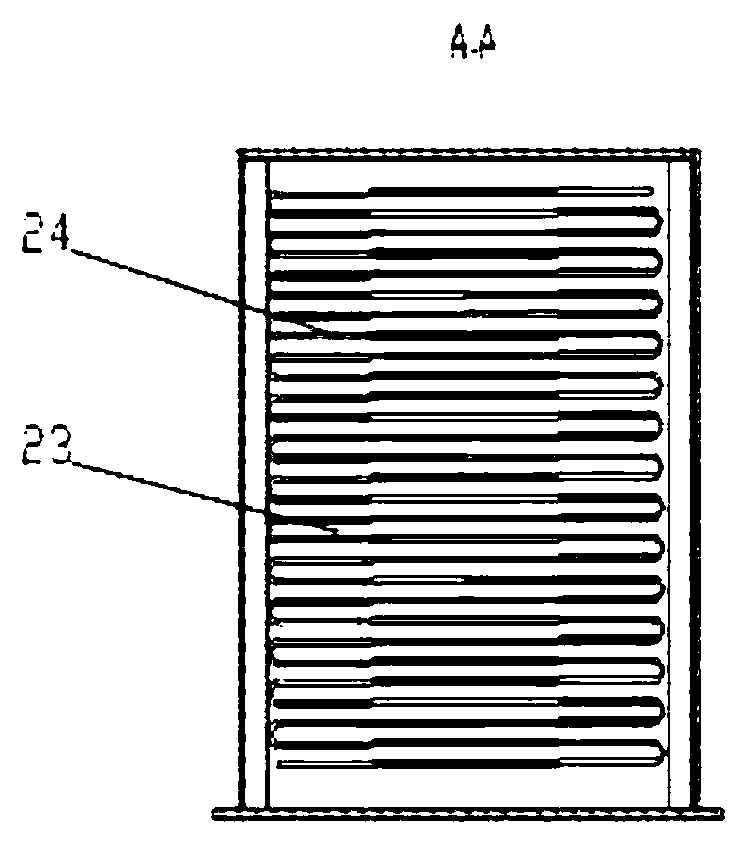

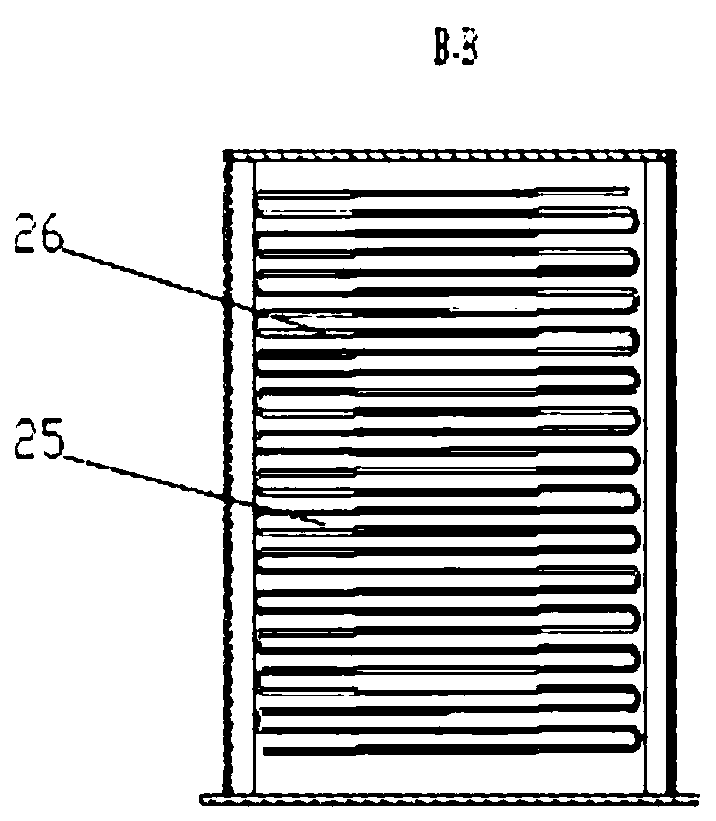

[0030] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-11 As shown: the present invention provides a piston and pneumatic dual-purpose 3D printing biological material extrusion test device, including a box body, a piston assembly 18, a mixing assembly, a pushing assembly and an air pressure assembly. The box body consists of a base 1, an upper Heat shield 6, front heat shield, rear heat shield 19, left heat shield 23, right heat shield 25 and support frame 21 are assembled, and left heat shield inner wall is provided with heating pipe 24, and right heat shield The inner wall is provided with a condensation pipe 26, the base is provided with two fans 22, the bottom of the upper heat shield is provided with a support 5 for fixing and positioning the piston assembly and the push assembly, and the bottom of the support is provided with a heating and clamping part 4, the The heating and clamping part includes a heat con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com