High-power LED heat dissipation structure based on thermoelectric refrigeration and micro-channel heat transfer

A technology of thermoelectric refrigeration and heat dissipation structure, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of low heat dissipation efficiency, reduce luminous flux, and affect the service life of LEDs, so as to improve work performance and reduce the temperature of the hot end, with good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

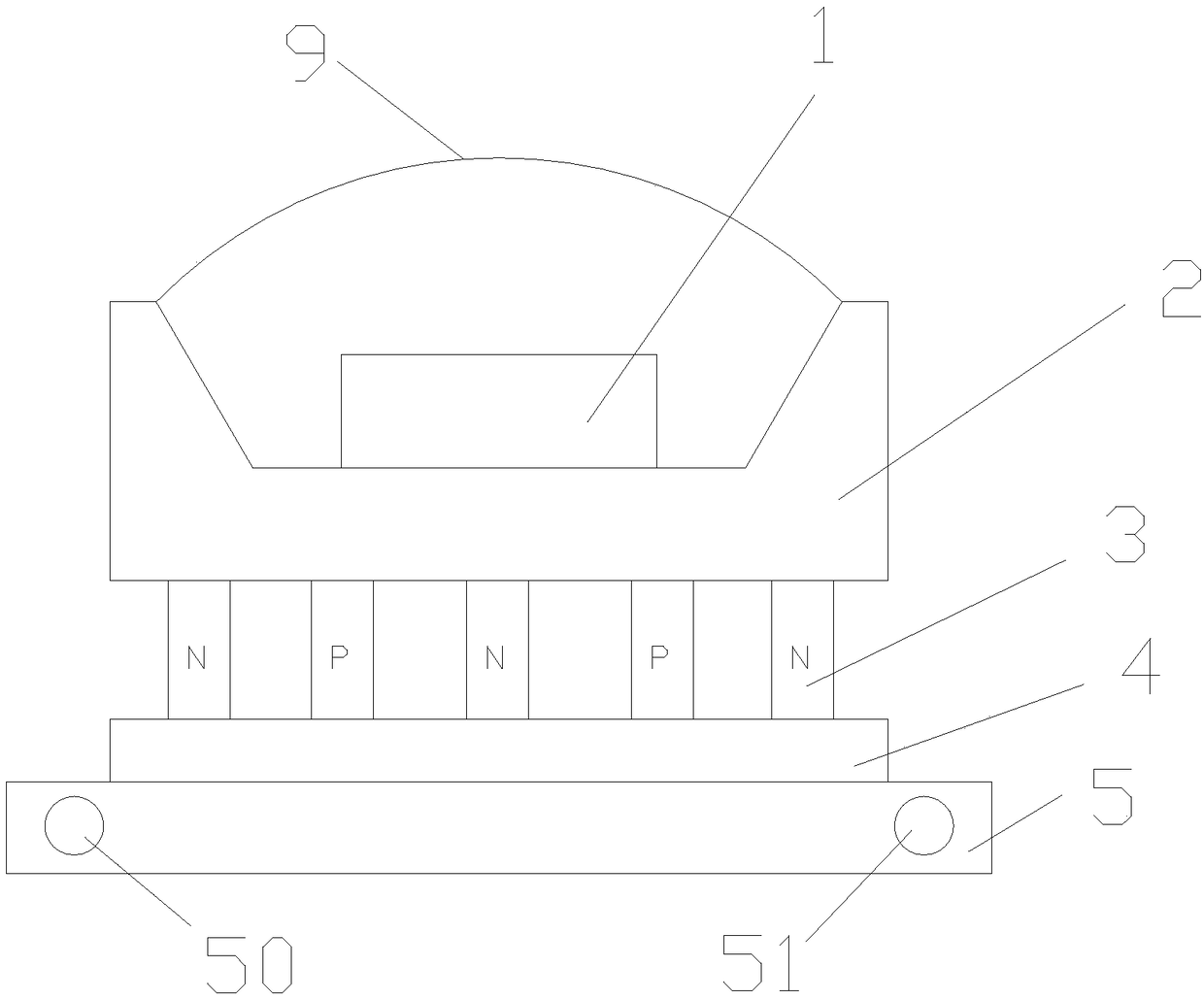

[0023] High-power LED cooling structure based on thermoelectric cooling and micro-channel heat transfer, such as figure 1 As shown, it includes a silicon substrate 2, an LED chip 1, a thermoelectric heat sink 4 and a microchannel heat exchanger 5. The LED chip 1 is attached to the cold end of the silicon substrate 2 to form an LED light source. The hot end of the silicon substrate 2 is connected to the cold end of the thermoelectric heat sink 4 , and the hot end of the thermoelectric heat sink 4 is connected to the cold end of the microchannel heat exchanger 5 . The LED chip 1 is connected to the silicon substrate 2 through soldering. Wherein the silicon substrate 2 and the thermoelectric heat sink 4 are integrally packaged, and the heat radiation end of the LED chip 1 is directly in contact with the thermoelectric heat sink 4 to improve heat dissipation efficiency. The thermoelectric heat sink 4 is fixedly connected with the microchannel heat exchanger 4 with crystal bonding...

Embodiment 2

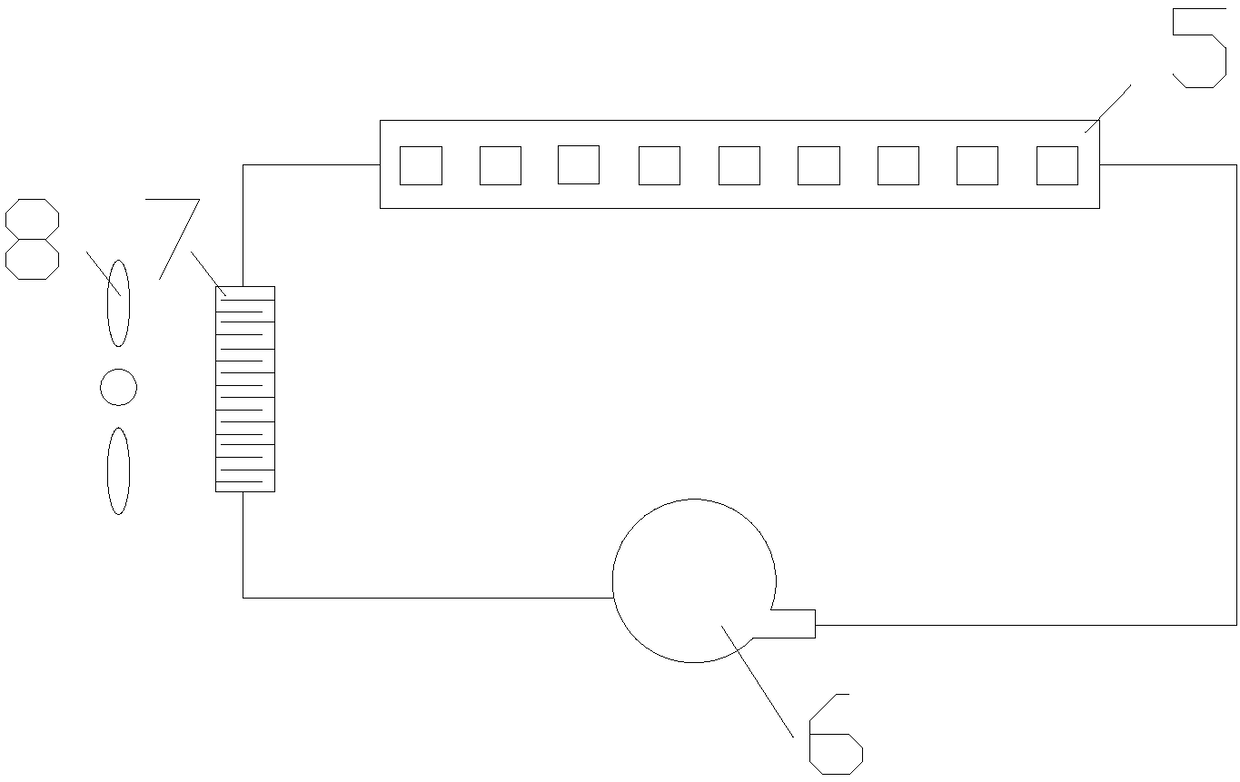

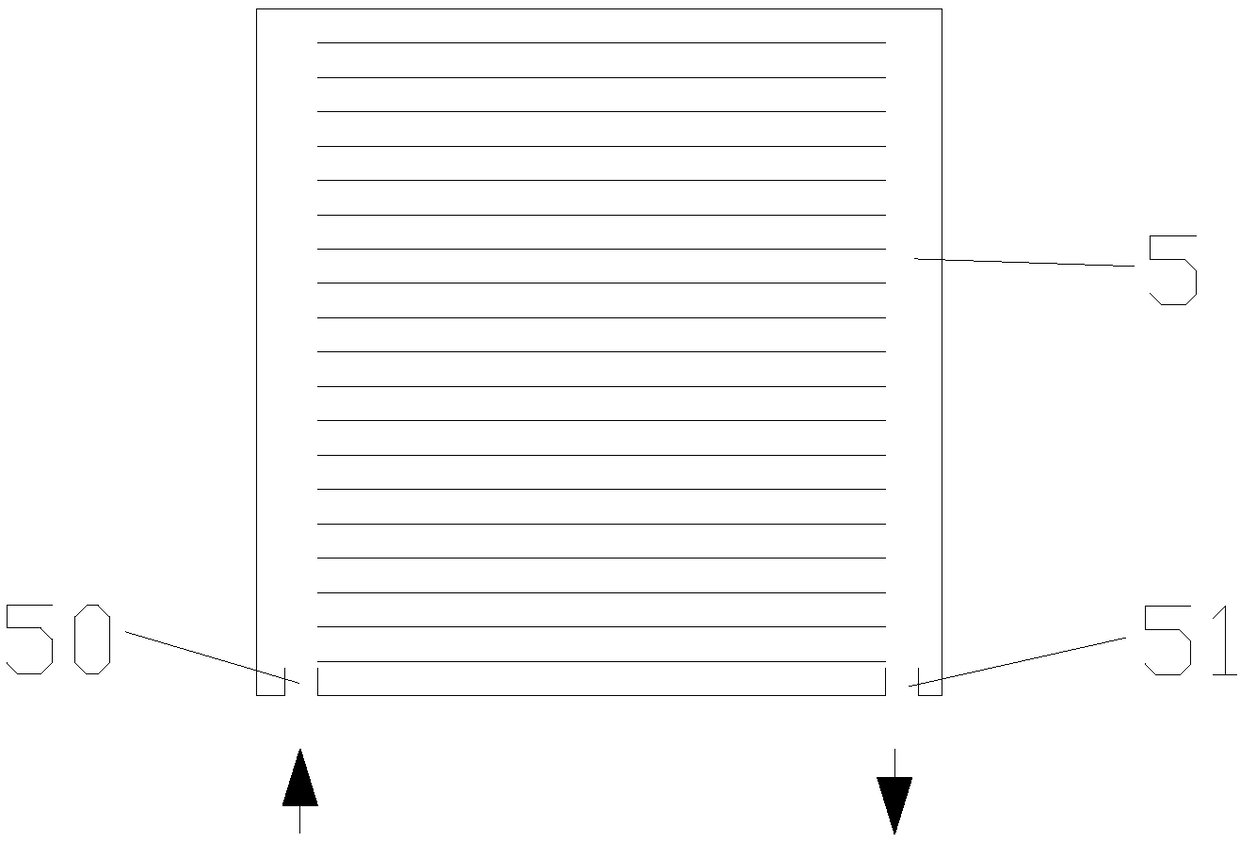

[0030] High-power LED cooling structure based on thermoelectric cooling and micro-channel heat transfer, such as Figure 4-5 As shown, it includes an aluminum substrate 21 , an LED chip 2 , a thermoelectric heat sink 4 and a microchannel heat exchanger 5 . The LED chip 1 is mounted on the aluminum substrate 21 to form the LED light source part. The aluminum substrate 21 is attached to the cold end of the thermoelectric heat sink 4 , and the hot end of the thermoelectric heat sink 4 is connected to the cold end of the microchannel heat exchanger 5 . The nano-fluid working medium is used for heat exchange in the microchannel heat exchanger 5, and the nano-fluid working medium is exported to dissipate heat through an air-cooled or liquid-cooled radiator. An arc-shaped transparent cover 9 is mounted on the upper surface of the aluminum substrate 21 , and the transparent cover 9 encapsulates the LED chip 1 on the aluminum substrate 21 . A fluorescent powder layer is arranged insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com