Preparation method of mulberry leaf qianliang tea and mulberry leaf qianliang tea

A technology of Qianliang tea and mulberry leaves, which is applied in tea treatment before extraction, can solve the problems of cloudy tea soup and difficulty in flowering, and achieve the effect of increasing flavor, appropriate density of tea germ structure, and moderate content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

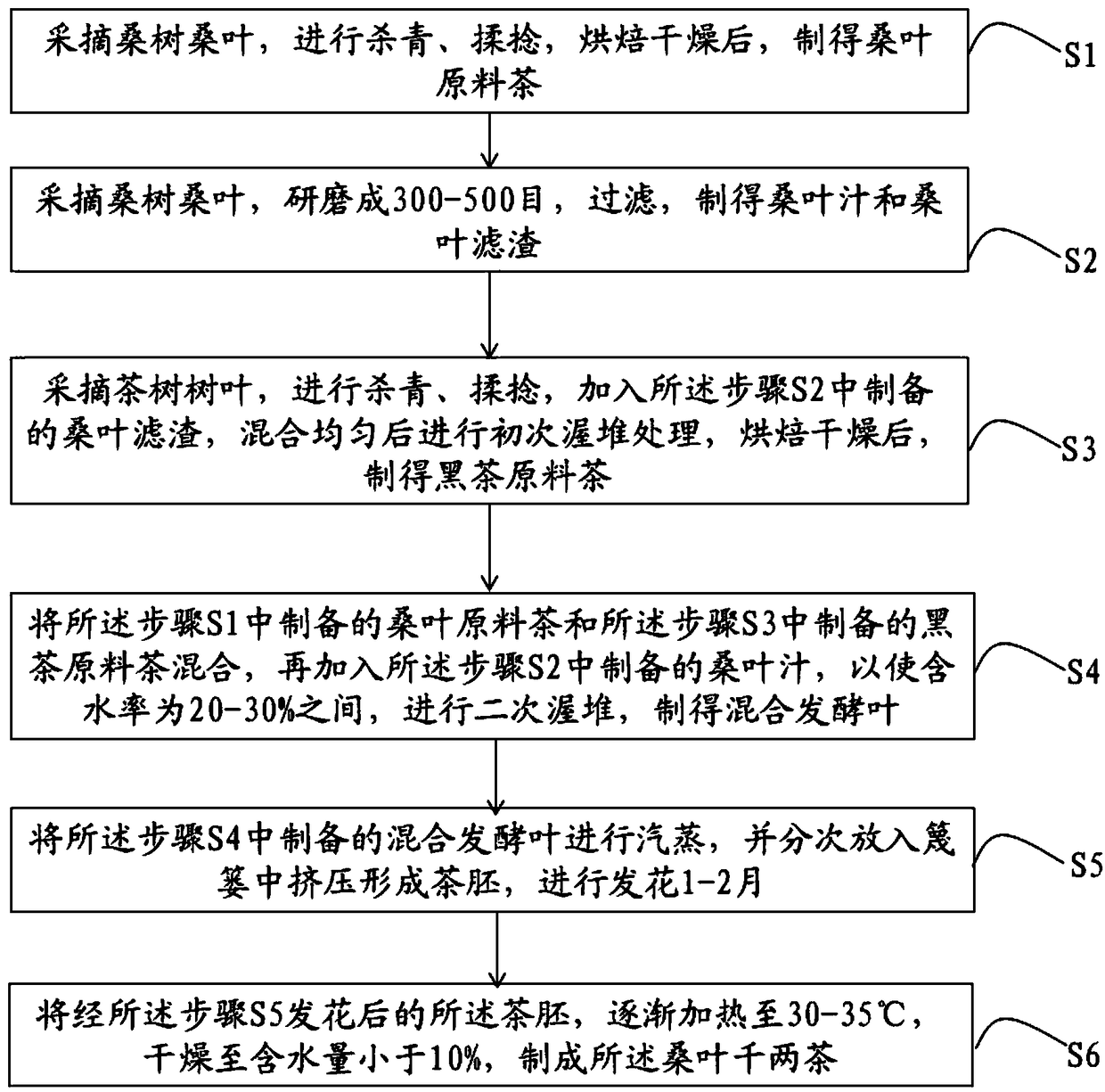

[0036] see figure 1 , is a schematic flow diagram of an embodiment of the preparation method of Mulberry leaf Qianliang tea of the present invention. The present invention proposes a kind of preparation method of mulberry leaf thousand two teas, comprising the following steps:

[0037] Step S1, picking mulberry leaves from mulberry trees, killing greens, kneading, baking and drying, to prepare mulberry leaf raw material tea;

[0038] Specifically, pick the fourth to seventh mulberry leaves of mulberry trees, wash them, and spread them for 1-1.5 hours at a temperature of 25-30°C; After being roasted and dried at 45°C until the water content is less than 15%, the raw mulberry leaf tea is prepared.

[0039] The fourth to seventh mulberry leaves of the mulberry tree, the veins of the leaves are formed, and have a certain degree of toughness, so that the raw material of the mulberry leaves can still maintain a complete shape after being piled up; the fourth to seventh mulberry ...

Embodiment 1

[0061] Pick the 4th to 7th mulberry leaves of mulberry trees, wash them, and spread them out for 1.5 hours at a temperature of 25°C; fix them for 2 minutes, knead them for 6 minutes; put them in and bake them at a temperature of 35°C until the moisture content is less than 15%. Prepare mulberry leaf raw material tea;

[0062] Pick the top buds of mulberry trees to the third mulberry leaves, grind them into 300 meshes, and filter to obtain mulberry leaf juice and mulberry leaf filter residue.

[0063] Pick tea tree leaves, fix them for 10 minutes, knead them for 8 minutes, add 1 kg of mulberry leaf filter residue to every 10 kg of kneaded tea tree leaves, mix evenly, carry out the initial heaping treatment at a temperature of 25°C and a humidity of 85% for 15 hours, and bake and dry at 35°C After the water content is less than 15%, black tea raw material tea is obtained.

[0064] Mix 7 kg of mulberry leaf raw tea with 35 kg of black tea raw material, add mulberry leaf juice to...

Embodiment 2

[0068] Pick the 4th to 7th mulberry leaves of mulberry trees, wash them, and spread them green for 1 hour at a temperature of 30°C; finish greening for 6 minutes, knead them for 2 minutes; bake and dry them at a temperature of 45°C until the moisture content is less than 15%. Prepare mulberry leaf raw material tea;

[0069] Pick the top buds of mulberry trees to the third mulberry leaves, grind them into 500 meshes, and filter to obtain mulberry leaf juice and mulberry leaf filter residue.

[0070] Pick tea tree leaves, fix them for 15 minutes, knead them for 3 minutes, add 2 kg of mulberry leaf filter residue to every 10 kg of tea tree leaves after kneading, mix evenly, carry out initial heaping treatment at a temperature of 35°C and a humidity of 70% for 6 hours, and bake and dry at 45°C After the water content is less than 15%, black tea raw material tea is obtained.

[0071] Mix 17.5kg of mulberry leaf raw tea and 35kg of black tea raw material tea, add mulberry leaf juic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com